Barometric Pressure Sensor MEMs - SCP1000-D01

Replacement:COM-09603. Although there is not a drop-in replacement, the BMP085 is a suitable replacement for most applications. This page is for reference only.

This is the very first absolute pressure sensor on the market to use MEMs technology to grant 17-bit resolution. Under ideal conditions, this sensor can detect the pressure difference within a 9cm column of air. Breakout board available below!

Please note: We now stock the ASCI rev C (IC label 'D01'). Please disregard the product image.

VTI's SCP1000-D01 digital absolute pressure sensors are intended for barometric pressure measurement and altimeter applications for 30kPa...120kPa and -20°C...70°C measuring ranges. The pressure and temperature output data is calibrated and compensated internally and the communication between the SCP1000 and its host micro-controller is realized using an SPI interface.

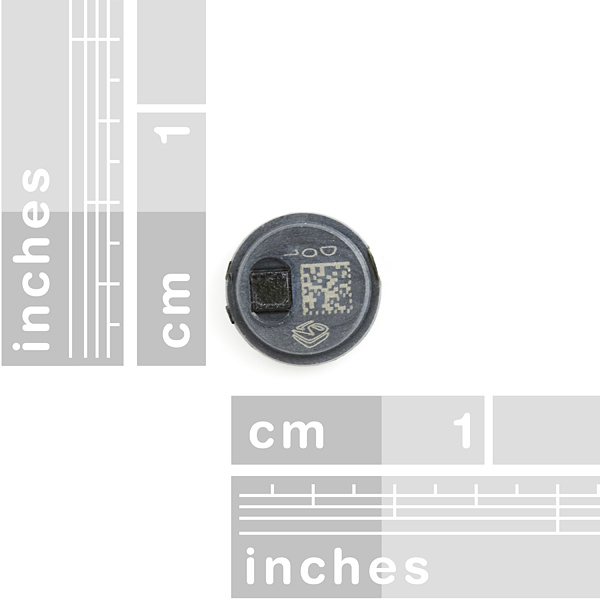

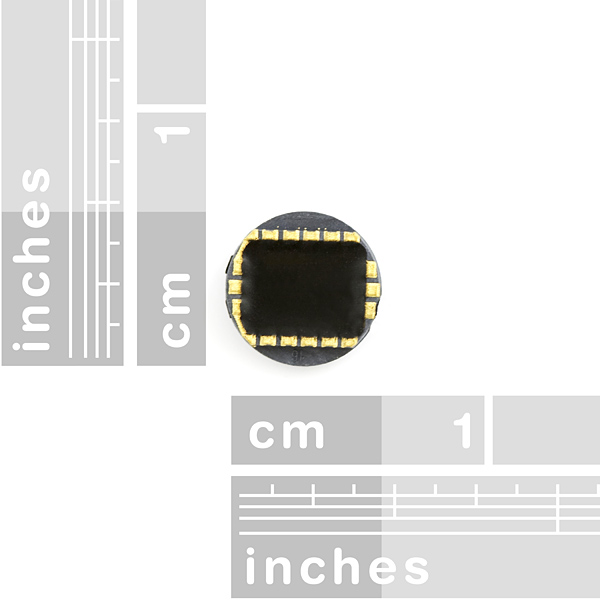

SCP1000 is comprised of a VTI's 3D-MEMS capacitive sensing element, a dedicated low power CMOS interface ASIC with on-chip calibration memory, 4 preset measuring modes and a LCP (Liquid Crystal Plastic) MID (Molded Interconnect Device) housing. The component is a surface mountable device incorporating a circular vertical wall for easy waterproof sealing.

Four user selectable measuring modes combine 17-bit resolution (9cm of air column) with low or ultra-low power consumption, or alternatively 15-bit resolution (18cm of air column) with high speed data read (9Hz) or less than 5µA and power consumption. For example, at Low Power mode, the SCP1000 has an overall resolution of 2 Pa (15cm of air column) and a power consumption of 3.5µA.

This unit comes in a newly developed plastic housing. Normal hot-air rework will destroy this sensor.

Note: If you plan on using this board in direct sunlight, we suggest purchasing the SCP1000 Gasket as shown below in the related items.

Features:

- 30 kPa - 120 kPa measuring range

- Single +2.4 … 3.3 V supply

- Four measuring modes plus power down mode

- On-chip linearization and temperature compensation

- On-chip temperature measurement

- Pre-programmed calibration coefficients, temperature offset and sensitivity coefficients in the EEPROM

- Standard digital output: SPI

- Small package size with I-seal gasket option, diameter 6.1 mm, height 1.7 mm

- Proof pressure 3.2 MPa

- Pb-free solderable component & RoHS-compatible.

- VTI Website

- SCP1000-D01 Datasheet

- Example SCP1000 application

- App note for DiosPro

- mbed Example

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

Had a lot of problems using this in helicopters. It would work most of the time, but if the wind hit the rotor wash the wrong way, it started oscillating. To get results as smooth as the uBlox5 GPS required delaying the SCP1000 output to greater than GPS latency.

Now that GPS is definitively going down to free up money for mortgage programs, more people should try pressure sensors in helicopters & get more data.

Soldering profile and rework guidelines are not in the datasheet, but in separate document: tn51_scp1000_assembly_instructions_rev07.pdf

I once used this method for fun, to desolder some

old hard disk ICs...

I took my mom's cloths iron, tuned it to max temp,

turn it upside down, place the PCB on the hot plate and ICs

desoldered in no time...

Guess you can do the same using soldering paste and your home brew PCB..... ( for PCB try toner transfer method with a laminator and print the circuit on a magazine paper... Best PCBs I got so far, and I'm trying nearly a year various toner transfer methods...)

Best Regards,

Lefteris,

GReece

One left, whoever needs it should get it now or forever hold your peace.

Works well in tri rotors. Keep it far away from rotor wash.

How do you solder this part? I have tried the techniques described in "SMD How To - 6, Hot Air Magic Tricks", but it is hard to "re-ball" these tiny contacts without damaging the plastic case. Does anyone have experience soldering this device?

Thanks!

Does a hotplate work for soldering this part?