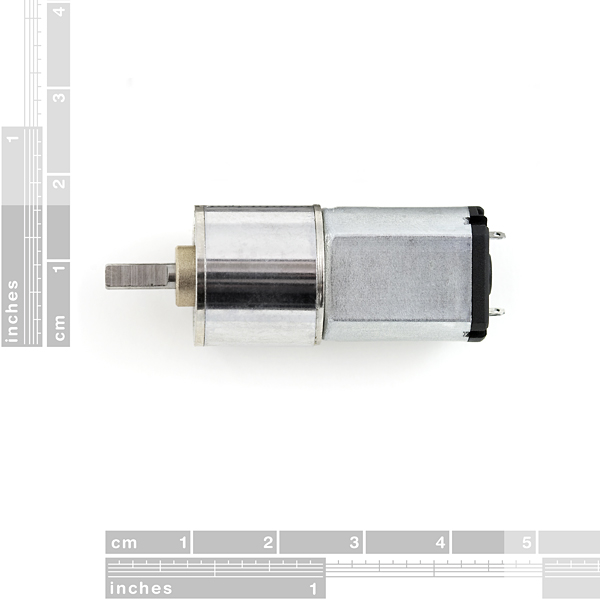

Mini Metal Gearmotor 100:1

Replacement:ROB-12008. Our new gearmotors have a gear ratio of 105:1 and 152 RPM, go check them out! This page is for reference only.

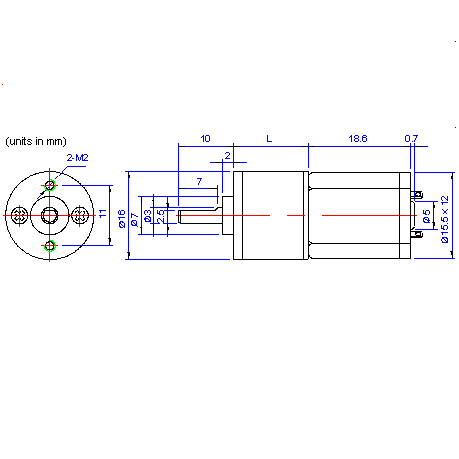

This motor has a 0.275" (7 mm) D-shaped metal output shaft that matches the Pololu wheel 42x19mm and 32x7mm. The face plate has two mounting holes threaded for M2 screws.

These motors are intended for use at 6 V. In general, these kinds of motors can run at voltages above and below this nominal voltage, so they should comfortably operate in the 3 – 9 V range. Lower voltages might not be practical, and higher voltages could start negatively affecting the life of the motor.

- 100:1 gear ratio

- 140rpm @6V

- 60mA @ 6V

- 26 oz inches torque @6V

Mini Metal Gearmotor 100:1 Product Help and Resources

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Rookie - You will be required to know some basics about motors, basic motor drivers and how simple robotic motion can be accomplished.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Rookie - You may be required to know a bit more about the component, such as orientation, or how to hook it up, in addition to power requirements. You will need to understand polarized components.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

For anyone who was interested, the torque on this unit (at 6V) comes out to about 0.1059 Nm.

Hi, just wondering, why were these retired? You guys still seem to carry the motor mounts for these motors.

has anyone tried to calculate the Voltage and Torque constant?

It seems that 26 oz inches for torque @6V is not correct. From the datasheet we have Rated Torque = 0.3 kgcm. Since 1 kgcm = 13.9 oz-in then it will be 4.2 oz-in for Rated Torque. You can check it here.

Has anyone run one (or more) of these off a single cell 3.7 LiPo? Thanks!

If I use 2 of these on the back of a vehicle, how should I mount the front 2 wheels? Where can I buy a shaft that works.

the units are in millimeters, right?

Does Sparkfun sell the screws that fit the holes on the faceplate?

Will the Pololu Wheel Encoder (ROB-09208) fit on this motor?

Anyone know if the gearbox on these is plantary or series geared?

I just took one apart - they're series. Several brass gears, metal pinion on the motor, a bunch of yellowish grease. (Best to hold the shaft downwards as you do this.)

hey Tom, by any chance do you remember the radius of the pinion?;-)

Could you use this to make a hand crank charger?

Does anyone know how much these weigh?

I get 23.4 g.

Is this compatible with the "Micro Metal Gearmotor Bracket"?

No. I believe that bracket is designed to fit the geared motors.

Thank you. Are there any other mounting kits that will do the job or do I need to design one?

Also, if you look at the drawings, the height on the unit looks to be 12mm, and the width to be 15.5mm, which are only .5mm larger than the brackets... would it fit if it was shaved down?

Any help is appreciated, thank you.

Unless you plan on sending this into space, some hot glue (preferably high temperature) or double sided foam tape should work just fine.

Shaving it down may be risky, but it's worth a shot.

It's funny that you mention "sending this into space." Would they work in space? Would they work at, say, 90-100,000 feet, by any chance?

My guess is the main issue would be temperature extremes, if stuff contracted at different rates it could seize. Datasheet says okay down to -10 C. Though, meh, I bet it's fine.

These were not designed to be sent into space, which doesn't mean they automatically won't work, but it does mean that it's up to you to determine that, by doing it or testing it in as close an environment as you can manage (dry ice, vacuum, etc.)

Haha, this will definitely stay on planet earth :P. I'll see what I can do. Thank you.

I've looked at a few similar motors, and I can't find a datasheet for them. Where are they?

Is the 140 rpm the output rotation or the rotation inside the motor?

if 140rpm is inside the motor that makes output to be 1.4rpm,so if you use 42mm wheel then your vehicle is gonna gonna cover 58.8mm in one minute so to cover 1 meter it would take app 17 minutes right

I believe that the 140rpm is actually output shaft RPM. A few pieces of evidence supporting this are: the Mini Metal 24:1 motor has a higher listed RPM and has the same internal motor connected to a different set of gears. Also, 1.4 RPM is extremely slow and would not support applications in hobby robots (which is what I believe this is target towards).

lol man this is exactly my point. i assumed that it's the output of motor not final shaft then proved it wrong as 1 meter in 17 minutes would be pretty scary :) i should have inserted a heading of conclusion. my bad

What is the diameter of the output shaft?

From what the diagram shows, the output shaft diameter is 3mm round, while the flat is 0.5mm deep.