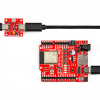

Soldering is one of the most useful skills you can have - and it truly is an art. With practice and patience, you can solder tiny pitch SMD components and rework your projects with the best of them. With that said, there are tricks to the trade that, while maybe a bit unorthodox, can make soldering a bit easier. Today, we have a tutorial from SparkFun Engineer Chris Taylor on the "Slap Method" for Through-Hole Rework. Check out the video:

In the above video, Chris is demonstrating how he removes solder out of some vias when he accidentally soldered a row of header pins to the wrong side of the board. To sum it up succinctly - you heat up the vias and then "slap" the board onto your desk - sending the solder flying and thus clearing the vias.

Keep in mind that though it sounds really simple (and truthfully, it kind of is), this can be a dangerous method and you should take precautions (like wearing goggles and long pants). We don't recommend it for beginners. Remember too that this can be hard on components. We have almost never had any issues, but the potential for harming something on your board is certainly present. Check out the tutorial for more explanation and pictures on how to use the "slap method." What non-conventional tricks and tips do you have for working on your projects? Let us know in the comments!

Don't forget to clip any plastic that holds your headers together. You will need to separate each metal header from one another so that you can then slap them out individually.

I just fire up my Heaterizer XL3000, melt all the solder at once, and slap out the intact header. This is surprisingly effective.

That's great for salvage. Maybe not so great for rework when you already have a lot of other components in place.

Not necessarily. Sometimes you can save the header if the pin count is short enough (probably no more than 3).

One trick I like is to add more solder until I bridge all the pins in a nice big blob. That allows me to heat them all up at the same time. It doesn't work as well with the 'slap the board' method though.

Sometimes what I do is sit on the floor, hold a pair of pliers between my knees, gripping the header or other multi-pin component. Then, holding my board in one hand and iron in the other I heat the solder blob while gently pulling up on the board. (obviously I already made the blob before getting on the floor)

This is really only worthwhile when you are short on headers and want to finish the project tonight (don't want to wait for more to ship). If you have a nice supply already just cut them apart, heat and slap the board just as described above.

...and the pieces come together. I was wondering how you magically ejected individual pins from a solid row of headers.

Well, if you hit it really hard... you'd like just break the board into pieces... Good question.

Honestly folks, a very bad idea. At our place we spend a great deal of time in microscope inspection of boards from one source. The problem is solder balls of all sizes that can get between close pins or under surface mount parts, and tiny splats of liquid solder. The culprit is rework in China with the "slap method" of cleaning the iron - smack it against a tin can. Cleans the iron great. Throws microscopic solder balls all over the place. If you have a separate place with some barriers, OK maybe, but very thoroughly inspect the board on which the slap method was used -- and you will still miss balls that went under parts. Even if the balls are too small to be a problem in your design, they cam fall onto much finer pitch parts in an assembly. Really, just don't do it.

I've been doing this (when appropriate) for more years than Chris has been alive. Yes, once in a while you get an unintended consequence, but overall, applied with a little common sense, it is a useful technique.

One important tip, unplug any vacuum tubes from their sockets before slamming the chassis on the table.

I think for most hobbyists, this is a non-issue.

A lot of these guys are still getting used to SMT, and don't use fine-pitch parts, so they likely won't really run into that issue.

I do reasonably fine pitch stuff with hot air, paste, and a microscope, but paste does the same thing - it leaves little balls of solder on the board for places where the paste was accidentally applied over the mask (I don't use stencils).

I just make sure to clean the board with alcohol and a brush after I use it. Simple enough.

Today's hobbyists are tomorrow's engineers, technicians, etc.

Why not learn techniques that minimize difficult to troubleshoot issues creeping into one's circuits? Later on, it may have a positive impact on one's career, where a prototype that is being demonstrated works reliably instead of failing at odd intervals.

I have found the following unit to be excellent for removing through hole parts. It is not cheap, but it outperforms desoldering stations that cost three times as much.

The secret is the slight vibration that the vacuum pump imparts to the desolder tip during desolder, which allows the vias to be cleaned better.

http://www.howardelectronics.com/den-on/sc7000.html

Perhaps SFE should look into selling them.

I do an alcohol clean as well. The disposable tooth brush with the battery from Oral-B is a good tool for this. However, my boards have big BGA parts and solder ball Pachinko under a BGA is something to avoid. If I had a point to make about hobbyists or beginners, it would be that they could be hanging their part over a motherboard and it will eventually rain some solder balls. Maybe harmless, and maybe the undiagnosable intermittent failure.

This technique coupled with a heat gun is a great way to get lots of components off a board at once, for instance when you're trying to salvage components from abandoned electronics. It's really satisfying how things like power transformers drop right off without much work.

I have recovered hundreds of SMD and PTH components using this method. It's a great way to keep cost down for a hobbyist.

You won't learn this sort of technique in an electronics tech school (for good reason). The slap method is good for removing solder from the lugs of switches and pots, but not much else. Slap method is bad for PCB mounted components. And don't even bother trying the slap method on a PCB that has 4 or more layers.

A demonstration of F=ma in action! You would make Newton proud-- actually, probably not. Sorry. He was somewhat of a hardass, being Sir Isaac Newton and all.

I Guess this method forgoes to soldor sucker.

Yeah. The mass of the solder helps it hold the necessary momentum to fly off the board. After using a solder sucker you just have the little bit that got sucked into the hole through capillary action and you will never get it out. (w/o adding more solder anyway)

Why slap the board onto the desk? I hold the board in my hand and "slap" my hand/wrist onto the desk, works just as good but it's a bit better for your board!

Well, once you've gotten to the point where you need to remove entire rows of pin headers you usually feel like slamming the PCB against your workbench anyway.

or is that just me?

I second that - or in my case, grow so impatient that you deliberately thermally stress the board to release your anger. Definitely lost that battle.

It is very hard to figure out how to actually buy something. Where is the icon/button fo "check out"??

Click the shopping cart in the upper-right corner. Then you can check out if you are logged in.

This needs to be fixed. The pages are loaded with icons; should new users click every single one until they get to a solution?

This got me last week - and again, just now - the page used to have text to click on for access to wish lists. It's gone now. Now you need to know to click on the down arrow in the upper right corner of the screen.

This is a poor idea for usability. Are you trying to alienate your users? You just made it harder to do business with you.

//curmudgeon mode off

I dunno, it makes sense to me.

The shopping cart is a picture of a cart, and it says "0 items" next to it. Pretty clear to me its a cart.

Once logged in, the dropdown makes sense - I've got my username there, next to my cart... that arrow is probably a dropdown menu that has to do with user and/or cart related stuff... and it is!

Top right is pretty common for "account stuff", so you don't need to click every single icon on the page - just follow your instincts and its supposed to be easy.

Where this falls apart is people who, for whatever reason, haven't yet developed instincts when it comes to this stuff. But unfortunately, the web is moving away from being obvious towards a cleaner look, with the expectation that most people know how things tend to work.

I noticed that google is going the same thing Sparkfun has done - they show your account name in the top right, and any settings are buried in a menu instead of just being listed there. I admit I didn't like that logging out became a two step process instead of a single click, but it seems thats the way the web is moving in terms of design, and I can't say that I see anything particularly wrong with what Sparkfun is doing that everyone else isn't doing.

I like the cleaner look, but I'll admit that it took me an embarrassingly long time to re-find wish lists after that change. ;)

Well, if you're looking for unconventional tips... When I had several large boards with lots of components I wanted to salvage I used a related method. This was for through hole components though not surface mount parts.

Fist I took off all the special or valuable parts I wanted individually by hand. After that everything else left on the board isn't worth the time to remove one by one. So I clamped the board upside-down and then used a propane torch in one hand and a shop air blow gun in the other hand. Keep the torch moving or you will catch the board on fire. Once you have all the solder in a few square inch area molten pull the torch back and quickly blast straight down on the holes with the air. It should be obvious that this method should probably not be used inside your house! Wear proper PPE and do it somewhere the molten solder spray won't hurt anything.

The yield rate for this method isn't a hundred percent; some parts will be melted beyond use and some will be stubbornly stuck to the board. However, if you have lots of boards that you are going to pitch anyway it's a quick way to salvage a lot of components.

Obviously, this is not following any temp profile and could be stressful for certain types of components so use common sense on what you reuse. I wouldn't use it on ICs but probably for resistors, capacitors, LEDs, switches, connectors, etc. I think it is a useful method when the parts would otherwise not be worth the time and effort to remove.

-Eric

I'm sure most have done this - but I'm proud of my recent discovery. I now use a breadboard to hold header pins while soldering them in place. Here's how I did it (inadvertent shameless plug for the EasyDriver from Sparkfun) http://www.flyinglow.ca/flyinglow/2012/02/shop-tip-soldering-pin-headers.html

Ugh! not so sure this is good advice, but sometimes there's just no better way. I once saw a guy use a test-tube agitator to buzz the solder off a board. Its all in the timing, you know. Sometimes re-soldering with extra flux helps to scavenge out better, then do the smack thing. After 40 years of spattering my jeans and leathers. not to mention the ills of loose lead around the lab/shop/kitchen -ack! -and how many times have you held solder in your mouth while two-handing everything juuuust right while you dab on that first joint...maybe why I've got the dubious honor of a swiss-cheese brain now. For me, a day without soldering/welding is like a day without sunshine, but I have learned: Dont wear polyester ANYTHING. -as in dont sit on a hot 40watt iron Wear facemask AND shoes. -as in balls-O-fire between the toes Dont work near carpet. -as in snip the solder out b4 old lady sees Sniff detect a hot iron. -as in melted fingers together lol k

Kilo,

More important than avoiding polyester is remembering that no matter how brilliant the inspiration was that woke you up, soldering naked in bed is a really bad idea.

Also, don't cook bacon in your underwear (or without your underwear).

Life lessons learned the hard way....

I'm baffled by this, I think for the educational value that Sparkfun provides, this is a bad method to be posting. The best solution is some variation of your own hot air rework station ($99.95). I use an industrial version of this that works great, is clean and keeps the temperature as low as possible, no lifted pads, splashed solder, or other mess. I use the in-line nozzle, aim it at the opposite side of the header and it drops out with no muss or fuss. Both board and header are in great shape to be re-used. If you are going to do SMT rework, you need the right tools.

Have you had any issues with pads or traces being pulled up? To be honest this doesn't seem like the best approach. You can remove components just as easily with solder and wick if you know what you are doing.

Hey today's my birthday, can I have a shoutout on the New Product Post? :P

+1 for "And boom goes the dynamite" quote! Love it...made me laugh when I saw that.O

Intresting. Removing the spacer and than each pin seperately isn t enough(i removed all the male/female spacers on a crappy knock off arduino shield this way in less then 5 minutes including cleaning the pads up )?

I can see using this to recover parts for your next project but if you fudge up? Mechanical stresses combined with the heat stressed metal could break a run free of the board or worse break a run at the pad causing all sorts of fun. As a certified PCB repair tech( US Navy 2M!!) i'm shocked and protest this abuse, and as an amature DIY geek, I'm not suprised and find it amusing.

I guess it's about the same as using a solder sucker (which I like a lot more than the braid). I'd trust the solder sucker more though, because in the time I'd flip that board around and slap it down some of the solder may have plasticized.

I've always called it the "Heat and Beat" method.

The best way to desolder something is still to apply as much solder as possible (so the heat equally spreads overall pin), to cover all pins and then gently pull out the header with a tweezer. So you can desolder almost all part that are non-QFN/MLF and non-BGA. The removal of the plastic will in most cases harm the board (as the pins get bent away) and also all the flying solder and pin parts are a hugh downside.

Hmm.. just spent 7 minutes watching a ridiculously big engine spinning a flywheel around.. wonder where youtube gets it's suggestions from

Good idea-I'll have to try it some time. I've had good results with a desoldering iron for about $20. It has in one tool a heating iron and a vacuum bulb that you squeeze before you heat up the solder, then let go to pull the solder out of the hole. Sometimes, the hole is stubborn-just add some fresh solder to the hole and vacuum again.

I always use "canned air" duster(tetrafluoroethane or whatever it happens to be) for de-soldering. It blasts heated solder completely away. And if you turn the can upside down you can use it to cool parts :)

How about : 1. Flooding all the pins with solder. 2. Heat it up. 3. Pull the hole header from the other side with a plier.

A similar way to do that is with an equally dangerous tool, a solder pot. Hold the board over the solder pot and then you can pull the part out with pliers. Don't want to spill the solder pot (like a volcano eruption of solder!).

That'll get the header out for sure. But it's likely the vias will still be filled with solder. If you try to push you iron into the hole, you might take the whole via out. You can try to use sodler wick or a solder vacuum, and those might work, but this is a nice quick-and-dirty trick!

A solder sucker will work beautifully on getting the solder out of PTHs, especially if you have a vice of some sort. Apply heat to one side, keep the sucker decently flush to the other side, once the solder is molten, suck it out.

I have more issues flooding the pins with solder.

didnt you post this video to youtube a while ago?

We uploaded the video a little over a week ago.

Great Scott!

Am I the only person that keeps a clean workbench?

Yes.

My workbench has a nice protective layer of everything in the universe on top of it...

You probably aren't the only person to have a bench they don't use... If I were in you situation I would donate my bench to someone that would use it :P

LOL Good one!

Remember, a workbench is for life, not just for christmas. (http://www.dogstrust.org.uk/az/a/adogisforlife/default.aspx)

Cluttered desk -> cluttered mind Empty desk -> draw your own conclusion This is how I justify my mess... er, desk/workbench.

all i know is my workbench is burried under the sparkfun order i just got

Funny cuz its the only thing in my possession that I can stand to have messy. Everything else is super clean. In short, yes you are.

yup.

I like mine messy, when it's clean I have a part of my brain going "Don't do that! You'll make it dirty." Said voice sounds suspiciously like my mum.