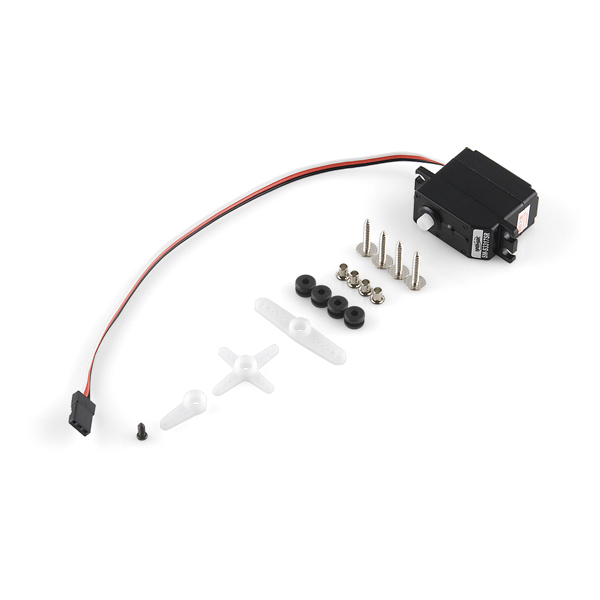

Servo - Generic Continuous Rotation (Micro Size)

Here, for all your mechatronic needs, is a simple, high quality continuous rotation servo motor. This servo is able to take in 6 volts and deliver 30.6 oz-in. of maximum torque at 0.14 sec/60°

A standard 3-pin power and control cable is attached. Check out the 'Includes' tab for all the hardware that is included.

- 1x SM-S3317S Full Rotation Servo

- 1x Single Arm Horn

- 1x Double Arm Horn

- 1x Four Point Horn

- 4x Rubber Grommets

- 4x 2x15mm Phillips Screw

- 4x Brass Eyelets

- Voltage: 4.8-6.0 Volts

- Torque: 27.8/30.6 oz-in. (4.8/6.0V)

- Speed: 0.16/0.14 sec/60° (4.8/6.0V)

- Rotation: 360°

- Dual Ball Bearing

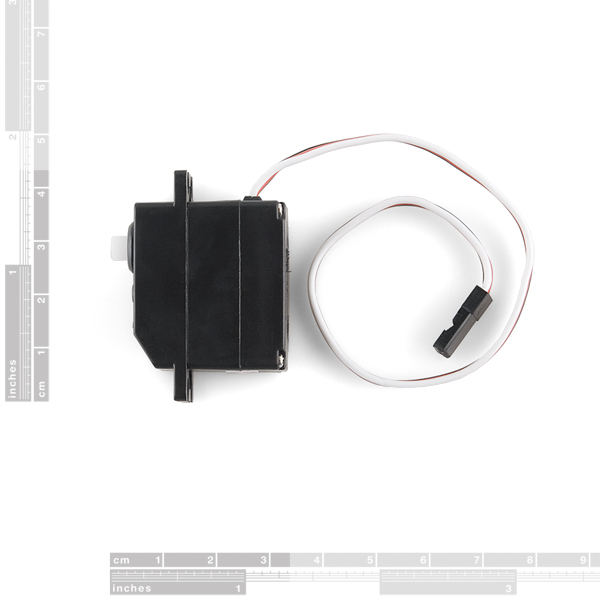

- Plastic Gears* 31.3 x 16.3 x 28.5mm

- Wire Length: 160mm

- Weight: 18g

- Dimensional Drawing

- Datasheet (SM-S3317S)

Servo - Generic Continuous Rotation (Micro Size) Product Help and Resources

Servo Trigger Hookup Guide

March 26, 2015

How to use the SparkFun Servo Trigger to control a vast array of Servo Motors, without any programming!

Hobby Servo Tutorial

May 26, 2016

Servos are motors that allow you to accurately control the rotation of the output shaft, opening up all kinds of possibilities for robotics and other projects.

Power Supply

Make sure that you use a separate power supply that is sufficient enough to power the Generic Continuous Rotation (Micro Size) Servo. 5V from a computer's USB port and Arduino microcontroller will not be sufficient enough to power the system. The servo can pull enough power to brown out your Arduino or not move the servo.

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Competent - You may need an understanding of servo motors and how to drive them. Additionally, you may need some fundamental understanding of motor controllers.

See all skill levels

Core Skill: DIY

Whether it's for assembling a kit, hacking an enclosure, or creating your own parts; the DIY skill is all about knowing how to use tools and the techniques associated with them.

Skill Level: Noob - Basic assembly is required. You may need to provide your own basic tools like a screwdriver, hammer or scissors. Power tools or custom parts are not required. Instructions will be included and easy to follow. Sewing may be required, but only with included patterns.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4.7 out of 5

Based on 3 ratings:

1 of 1 found this helpful:

Does what it's meant to do!

Plugged it in to an RC receiver, set up the mixes on my transmitter, and away the little robot goes! Solid construction, and has a built-in dead space to prevent small variations in signal from making it twitch.

My only complaint about it is that the response to the input signal is not linear. So, from 0-10% off center it's still, and seems to reach full throttle about 70% off center, leaving the top 30% of signal unused. Sure, I could account for that in the mix, but it's a pain.

servo generic continuous rotation

Very good product!

Great servo

This servo worked perfectly. Please note that an Arduino's 5 volts isn't enough to power this. If you're using an Arduino, use an external 6v battery pack. I used this one: https://www.amazon.com/x1-5V-Battery-Holder-Switch-Wires/dp/B01C5J4J78/ref=sr_1_3?ie=UTF8&qid=1515027432&sr=8-3&keywords=4xaa+battery+holder

I think it would be useful to know how much current the servo draws when it's stalled.

What is the diameter of the output shaft? Thanks a lot

I mesured 4.8mm.

Would these fit in: http://www.ebay.com/itm/Alum-Metal-6Legs-Hexapod-3DOF-Robot-Spider-Frame-Kit-Silver-Matt-for-Arduino-/281162946003?pt=Radio_Control_Parts_Accessories&hash=item41769e15d3

Or: http://www.ebay.com/itm/6-Foot-Robot-6-legged-robot-Hexapod-Spider-Robot-Frame-Kit-Servo-Bracket-Ball-/281098718639?pt=LH_DefaultDomain_0&hash=item4172ca0daf

If not are there any servos sold here that fit in one of these?

Does anyone know how much current these draw?

Could I get two of these and put wheels on them for a robot? If so, what is the diameter of the shaft? Do they fit standard robot wheels?

How many intermediate positions this servo can hold?

What is the minimum angular response?

If you are asking those questions you are looking for this servo: http://www.sparkfun.com/products/10333

which has an Operating speed of 0.18sec/60 degree (6V) and is a standard servo rather than continuous.

Please clarify what's meant by "continuous full-rotation servo motor". Is this a servo with a 360 degree range or is it a continuous rotation motor? <br />

<br />

"Full rotation" and "360 degrees" are consistent with each other, but neither is consistent with "continuous", as a "continuous" motor can turn an infinite number of degrees, not just one rotation.<br />

<br />

Adding to the confusion is the "Rest point adjustment" claim. Although a servo, regardless of the number of degrees of its range, has a "rest point", a continuous rotation motor does not.<br />

<br />

TIA,<br />

Eric

It is as you suspect, and as the description describes. It is a full rotation, continuous motor. It rotates continuously, or infinitely.

Otherwise, it would be a 360 degree servo motor.

Robert C.,<br />

<br />

Thanks!<br />

<br />

I see the "rest point" isn't there any more, but the "360 degree" still is. <br />

<br />

Also, the description still says "servo". If this were a servo motor, it would take a set point and adjust its position to be at the corresponding location, using internal feedback. If this is a continuous rotation motor, it takes a set point and scales its speed depending on that set point, but there's no closed loop control, so it's not a "servo". This device may very well be in a package typical of servos and may even have been a servo before someone broke the feedback loop, but it's not a servo if it's continuous rotation, open-loop control.<br />

<br />

Eric

Well, it still is a servo, but with velocity as the controlled quantity, instead of position. The setpoint is a desired velocity.

That's true only if it has closed loop control of the velocity, using an encoder or similar for feedback. I don't see any indication one way or the other but my guess is that it does not have that.

That might be true in a technical sense, but it is common practice in hobby robotics to modify servos by detaching the motion from the position potentiometer, thus closed-loop position circuitry becomes an approximate proportional velocity control.

I do not like the ambiguity of the term either, and I am not crazy about the accuracy of a hacked servo, even if they are, in this case, manufactured in this way - but its a cheap way to get decently controllable speed/heading for a differential drive robot.

Maybe a better name would be "Premodified continuous rotation servo" or something along that line for those shoppers who expect a very specific thing from the term "servo"

Normal Servo: give it 1.5ms pulse train and it will go to 90 degrees. Adjust the pulse to adjust the angle.

Continuous Rotation Servo: give it a 1.5ms pulse train and it will stop. Adjust the pulse to adjust the direction and speed.

Is it possible to get position feedback from the potentiometer inside the motor, like you can on standard hoby servos.

Does anyone know where one could find some wheels for these things? Thanks

Hey! Do you know what frequency and what pulse width of PWM can control this motor?

HI I WILL BUY THIS SERVO TO FIXED IN CLAW IS THAT GOOD??

HI free_matrex2010. I CAN'T UNDERSTAND YOU! USE PUNCTUATION TO HELP ANYONE TRYING TO HELP YOU

Can this also be used with http://www.sparkfun.com/products/10332 ?

http://www.sparkfun.com/products/10333 is listed as the related product but it is sold out. Thanks.

Sorry for my ignorance. What is the function of orange pot on the backside? I find it effects the sensitivity of the pwm, somehow.

I have 2 of these servos. While connected to an Arduino and the servo library

I wrote code where I could input value from keyboard(ms) and show value in serial console. Servo was moving accordingly

Servo library accepts millis as well as degrees inputs and to translate 180 degrees into millis you divide 500(ms) by 90(deg)

There you have 5,5ms = 1 degree movement = minimum speed of continuous servo

that was more or less the minimum required input to keep servo moving constantly.

//UndCon

I still can not get my servo to not move, it was like this when i got it. Adjusting the screw was probably a mistake, ( I am still a novice with micro controllers). I might just buy a regular servo seeing how that is all i need, unless i can interface this servo properly, would you mind sending me the code you made? You could put it on http://pastie.org/

i bought two of these and they dont work with the arduino? for some reason if i try to only move one both of them seen to move together, when i only programmed one.

How did you interface the motor with the arduino? I can not even get the motor to work properly, the second i set pin 9 as output, it just keeps on spinning no matter what I do.

Are you using the example that comes with the Arduino IDE for servos?

Yes and No, since this is a full rotation servo setting the position does not work, so i use the servo library, and attach to pin 9, and then it just begins to spin, I have tried twisting the screw on the servo to adjust the hault position with no luck. I have also used http://www.arduino.cc/cgi-bin/yabb2/YaBB.pl?num=1278145608 to try and interface it, but I can never find the hault position

that might be part of the problem. when i've used these, I just left them alone, used the servo library and when i told it to go to 90, it stayed still. when i told it to go 91, it moved slowly one way, and 89, slowly in the reverse direction. the further the number was from 90, the faster it went in that direction. you might have adjusted out a halt position. try writing a simple sketch that sweeps it, and see if it ever stops moving. for continuous rotation servos, you might want to use the write microseconds command as well.

When I just ran a test on my servo I purchased, I found that 'center' was actually 94. Not sure why the difference is, and don't even see it as a problem, but am mentioning it here so no one gets discouraged if they experience different results. You just need to play with it to see what values do what for your servo.

Ok so now I am playing with the servo a few hours later, and find that the center point has moved to 93. Nothing changed except I unplugged the Arduino and waited a few hours. Not sure why this would be, but I can see this being a small problem in some applications.

I am not sure if detaching the servo is a good way to stop it in position or not, but plan on trying this as well.

Can someone tell me the size of the shaft?

do you guys sell any compatible spool/pulley type things that this motor can drive? basically i want to pull down a rope to open a small door.

I little late but in case anyone else asks. Screw one of the servo horns (the white plastic parts) to what ever you need to turn and use it as a hub.

Unfortunately, they do not.

Does anyone know the specs for the motor running this servo? I accidentally popped the capacitor in it, and have cut off the IC to control the DC motor manually.

Thanks

Tormod

why is that this same motor (SM-S3317S) of 60 degree rotation has torque of 2.2kg-cm, while this one has 4.8kg-cm , even though everything else is same ???

"Torque: 3.3-4.8 kg/cm (4.8-6.0VDC respectively)"

I believe the unit you mean is kgcm, not kg/cm. 3.3 kgcm = 45.8 oz*in, which is average for an average servo. I'm buying four of them... will report performance soon.

what do I need to control this one from arduino?

Nothing, just the arduino and motor:

http://arduino.cc/en/Tutorial/Knob

Hey man, I never thanked you for the reply. So, thanks a lot :)