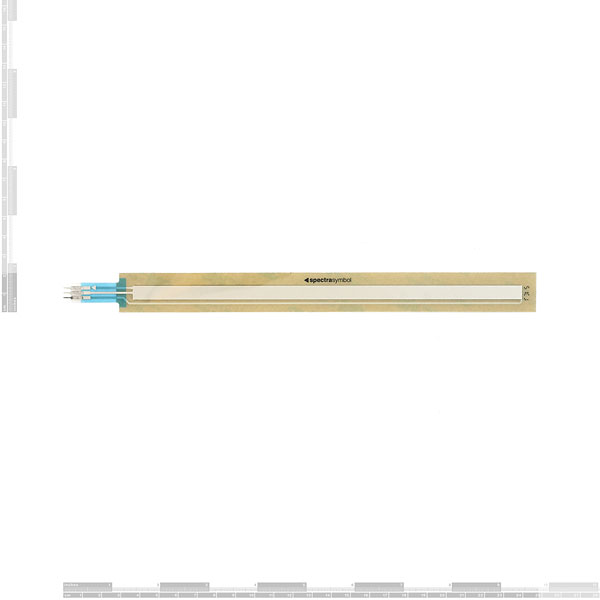

SoftPot Membrane Potentiometer - 200mm

These are very thin variable potentiometers. By pressing down on various parts of the strip, the resistance linearly changes from 100Ohms to 10,000Ohms allowing the user to very accurately calculate the relative position on the strip. Can be used as an accurate positional indicator for CNC head positioning, variable user input (volume level input for example), straight user input (multiple button areas translate to given resistance levels), and many other applications.

Unit comes with adhesive backing. Connector is 0.1" spaced and bread board friendly. However the connector does not fit nicely into standard female headers because the pins are too small.

Note: These potentiometers work great with a finger, or stylus.

SoftPot Membrane Potentiometer - 200mm Product Help and Resources

SoftPot Hookup Guide

May 5, 2016

Equip your Arduino project with a sliding soft potentiometer to monitor position or adding linear control to your project.

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Noob - You don't need to reference a datasheet, but you will need to know basic power requirements.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4.3 out of 5

Based on 3 ratings:

Muy practico

El articulo funciona correctamente, el envio fue rapido en general Exelente

very very good and wonderful alignments

works very well, good adhesion and resistance is perfect and taught

How wide is the soft pot? The data sheets don't mention it's size?

As per sprectras website https://cdn.shopify.com/s/files/1/0578/4128/7283/files/SoftPot-Series-Datasheet-v2019a.pdf?v=1674511991 the width is 20.32mm overall and the active area is 7.11mm

Since the datasheet isn't tremendously helpful I wrote up a blog post explaining how to use a SoftPot: http://qqrs.github.io/blog/2013/04/22/interfacing-a-softpot-sensor-to-an-adc/

Does anyone know the force required to activate a SoftPot?

The SoftPot requires around 1 newton, the HotPot requires around 1.5 newtons. It varys slightly with tempeature. The SoftPot never goes above 2 newtons, and they HotPot never goes above 5 newtons (with extreme cold).

Correct me if I'm wrong, but I think:

1 Newtons = 0.22 lbs

2 Newtons = 0.45 lbs

5 Newtons = 1.24 lbs

yeah, I tried this out, and you were right about it taking 1 Newton. The thing I don't like about this component is that it isn't that fingertip-friendly. You can fix that problem by putting some smooth, thin surface over the top. Certain types of paper work really well.

I want to mount it with a linear actuator to measure the stroke opened.. is it precise enough to do so??

I've noticed that these SoftPots are noisy and difficult to work with as far as controls go, so I made a python script that averages 100 sample values from the SoftPot and then averages it out, divides it by 1000, then multiplies it by 100 and voila you get a reading that is easier to work with...

the following Python script you can run on the Beaglebone to reduce the crazy noise and output a better value range to work with, Script URL: http://pastebin.com/hfekCBuW

I found out using this script that when nothing is being pressed on the soft pot anymore it resets to the highest value. Hope you guys like this!

I am having a very strange issue with the softpot. When a hand gets within 3 inches of the softpot, it activates the motor on my Arduino board. I mounted the softpot on a piece of foam to try and cancel out any electrical interference it could be receiving but the problem still persists. Any experience with this issue and how to resolve it?

A couple things that may help

-Mounting/surrounding components on/with dielectrics (things that don't conduct electricity) only stops them from having direct electrical connections with other components and wires. So, for example, if you wanted to make sure the electrical connections on the bottom of an Arduino don't accidentally get shorted by some loose wire, you might glue it down and seal it.

While doing this will stop you from shorting things out, it doesn't stop noise. In some cases, it can actually increase the noise because the dielectric gathers a static charge and can randomly discharge in the air or cause voltage fluctuations across a circuit (which is bad when you don't want it to happen).

If you are really concerned the pot is creating a lot of noise, mount the pot to a metal surface and then cover the top with the plastic from the static bags hard drives and other static sensitive devices ship in.

-My guess is what is causing your problem is a "floating pin". This happens when you don't pull down a pin with a resistor when you want to connect a button to it. What happens is that random noise (be it ambient electrical or RF) causes the pin to randomly read high and read low. If you have a button that is controlling your motor without a properly connected resistor, the pin connected to said button can go haywire. Take a look at the third picture here to see how you would need to wire a button correctly.

I'm also having the floating problem on this SoftPot. I am simply using it as a position sensing device to know where my finger is pressing on it across from left to right. When I add a resistor in between the center pin and analog pin on the arduino mega, I get a 'exponential' type reading across the potentiometer. I still get the sporadic reading every once in a while, too, so the pulldown resistor does not seem to be working for my purpose. Any ideas? Much appreciated!

What is the resistance when no finger is pressing down on the sensor? If there is 5V across pin 1 and 3 then what is the output voltage at pin 2 when no finger is pressing on the strip? Also with 5V across pin 1 and 3 what is the voltage on pin 2 when a finger is pressed at either end of the strip?

I asked the manufacturer this question: resistance is 0 ohm when no finger is pressing down on the sensor, so the voltage at pin 2 in your example would be 5V.

I don't know the answer to your second question, but according to the specs this is a 10k pot, so my guess would be 0ohm at one end and 10kohm at the other.

I would guess that when no finger, it is floating, so you need a big pullup/down resistor.

IDK about the upper and lower ranges of the output though.

should be 0V reading if nothing is pressing down on it. 10kOhms per 100mm. Should be 0 at one end and 10kohms per 100mm.

How precise is this device? and how wide is it? what about response time for the arduino?

Please refer to the datasheet for your first 2 questions. As for as 'responsiveness' it is as responsive as you can sample it.

ok, I'm using this for my 7th grade science fair project: SpiBot Proto I. It controls the scissor lift on the robot.

Can this be bent? and can the extra space on the sides be cut?

As far as I know, yes, the clear plastic on the sides can be cut and it can be bent. But be warned though, if you bend it it will be hard to flatten it out again.