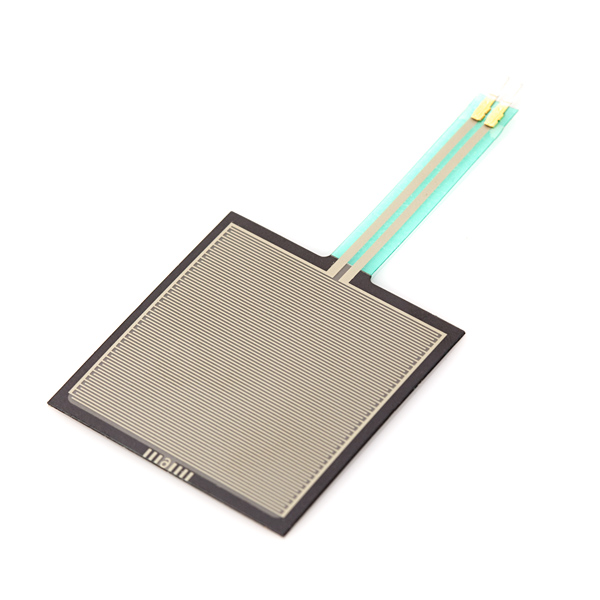

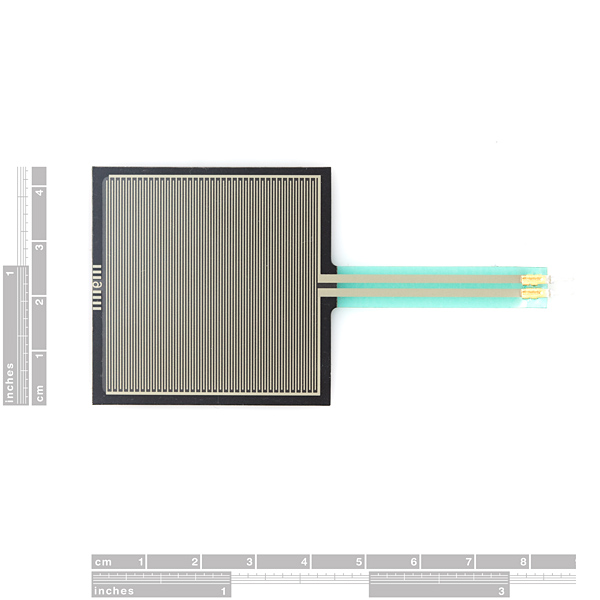

Force Sensitive Resistor - Square

This is a force sensitive resistor with a square, 1.75x1.5", sensing area. This FSR will vary its resistance depending on how much pressure is being applied to the sensing area. The harder the force, the lower the resistance. When no pressure is being applied to the FSR its resistance will be larger than 1MΩ. This FSR can sense applied force anywhere in the range of 100g-10kg.

Two pins extend from the bottom of the sensor with 0.1" pitch making it bread board friendly. There is a peel-and-stick rubber backing on the other side of the sensing area to mount the FSR.

These sensors are simple to set up and great for sensing pressure, but they aren't incredibly accurate. Use them to sense if it's being squeezed, but you may not want to use it as a scale.

- Overall length: 3.5"

- Overall width: 1.75"

- Sensing area: 1.75x1.75"

Force Sensitive Resistor - Square Product Help and Resources

Using the SparkFun PicoBoard and Scratch

November 11, 2014

Here are a few tips in using the PicoBoard with Scratch v1.4. The PicoBoard allows us to write Scratch programs that interact with a variety of sensors on the PicoBoard. These sensors include: sound, light, a slider, a push button, and 4 external sensors (A, B, C, and D).

Force Sensitive Resistor Hookup Guide

May 5, 2016

How to hook a force-sensitive resistor up to an Arduino to measure pressure variances.

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Noob - You don't need to reference a datasheet, but you will need to know basic power requirements.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4.1 out of 5

Based on 9 ratings:

Good sensor

It's been pretty easy to set up this sensor and it works perfectly. You can play a little bit around with resistors in order to set the sensitivity and works like a charm.

Nice product but..

While we see force sensitive on this product, this sensor proportionally responds to forced size.

Uneven force measurements across locations on sensor pad.

Did basic testing by placing small weight (placing AAA battery -ve side down) at different location on the sensor pad and observed that the sensor reports different force (resistance) depending on location of the weight.

Good, Flexible and Works Perfect

Good sensor. It looks very nice and good that it's flexible. Works perfect

Works great!

Small, sensitive, works great for my needs. The example code and circuit work flawlessly.

Fragile, inaccurate

These sensors absolutely suck. They are super fragile. The leads that connect to the sensor (at the end of the green strip) come off very easily (meaning once they are off, the sensors aren't useable anymore) and my team and I have had zero success with trying to re-attach them. We bought around 6 sensors and tested them with the same weight on each sensor and each output different measured values.

These sensors are simple to set up and great for sensing pressure, but they aren’t incredibly accurate. Use them to sense if it’s being squeezed, but you may not want to use it as a scale.

Worked perfectly

I changed my design plan so it won't work with my current project but I will definitely have a use for it in the future.

Love these FSRs

I have used these FSR's for over a decade. They are so responsive and sensitive. I use them in musical instruments. The only bad thing I can say about these is that you can't get any fluid near them or they will be destroyed. If I try and clean my instrument or wipe it down, I can't get near these FSRs. But these are awesome.

This works well for me. I am using to measure the amount of vacuum when doing vacuum bagging and use that to control the vacuum pump so that it stays in the correct range. More details at https://github.com/fluffy/vacuumCtrl

At the risk (which I accept frequently ;o} ) of sounding picky:

1) "Force" and "pressure" are not the same thing, but the terms appear to be used interchangeably in the description. It would be helpful to know which this senses. If one exerts 10 newtons of force on a 1 cm X 1 cm area of this sensor, that's four times the pressure of the same 10 newtons on a 2 cm X 2 cm area, but the same force. How, if at all, does the sensor respond differently to the two loads?

2) Speaking of "newtons", a "newton" is a unit of force. Neither a "gram" nor a "kilogram" is; they are units of mass.

3) Lastly, unless plane geometry has been changed radically in the ~four decades since I studied it, there's no such thing as a "square, 1.75x1.5" anything.

Eric

Hi Eric,

Thanks for pointing this out to us. I will have this description reevaluated for proper information. We will try to address your concerns, and questions in the revised description.

Thanks,

Timothy

:)

After reading the documentation, it appears it senses a not quite linear function of pressure times area. Thus, it is kind of a pressure sensor, and kind of a force sensor... the description shows the lack of clarity fairly well.

If you're interested in one or the other, create a consistent contact patch, and calibrate according to your needs. I suspect that it will be simpler to make it "just pressure", but it all depends on what's at hand.

As to your example, alas... it appears the answer may even depend on which cm^2's you choose to test.

But I'll have to completely grant you the "square" issue. Unless they're trying to very obscurely describe a measurement of 2.625 inches on each side.

Neat! a Jedi Sensor!

I really want to build a lightsaber now...

Could this be insulated and used as a water pressure sensor (dividing the force by the area)?

The description says that the FSR can sense force up to 10kgs. What would happen if it had more than that, say, human weight? :) Would it just max out or is there risk of damage?

Hey if the product is available again?

Are these waterproof? I'm thinking this might be a nice solution to a rain sensor

would like to use 20 of these to line the floor and seats of my car to make some form of security, given that when armed, if someone gets in to either take my car or something in my car, they'll have to get inside, and when they do, one is pressed and sets off the alarm. Combined with window shatter sensors and pressure switches, if they pick the lock and open the door, alarm. If they smash the window, alarm.

I will be firing a soda can at a shield at about 100psi. And i would like to measure the force the soda can hits the shield with. should i go with a accelerometer or would a impact sensor suits my needs best? i was also considering mounting a sensor on top of the shield instead to just measured the vibration of the shield.

I think the Bildr tutorial has it's description a little backwards. The technique it shows is correct but it description of WHY is wrong...I think. They say:

In the last two paragraphs they suggest that the voltage reading goes down the greater you press on the FS. That hasn't been my experience. Am I missing something?

This may be a better tutorial.

I would like to use the FSR in a mailbox so when an envelope is placed on top of the sensor it will trigger. Would a standard, around 1 oz., piece of mail work or it is not that sensitive? Any other sensor suggestions? Light sensors would not be an option because the back area is always lit.

Minimum mass it can sense is approx. 100g, which is a bit less than 4 ozs.

Hello, since I'm new to this would this be better for sensing impact or this one: https://www.sparkfun.com/products/9196

I want to make something that can detect the force and magnitude of an impact (for example, if I were to hit it with my fist) and was wondering whether this product or the other one would be a better option. Thanks in advance.

Is there a maximum pressure/weight for these? I couldn't find anything in the documentation. I don't want to measure weight, just identify if it is present which an FSR seems ideal for. What I want is a pressure sensor that detects if someone is standing on a metal plate.

It might be of interest to users that it is the conductance of these sensors that is linearly proportional to pressure, not their resistance. When you use them in a simple voltage divider circuit the voltage output will be highly non-linear, i.e. a 1/x curve. For a linear voltage output proportional to pressure you need to drive it with a constant-current source. The simplest way is to connect the FSR between a fixed reference voltage and the input of an op-amp inverter (with no other resistance in series with the FSR). The feedback resistance and the value of the reference voltage will determine the output range. Of course, the output will be inverted and you need to set up the opamp's power supply properly.

Wish there was a better solution for mounting this. Mine busted pretty easily while trying to bend the tail.

i too saw the ink crack with very little bending, anyone have any input on a solution?

This sensor limit is 10kg(9,8N), the same as the 0.5" one (SEN-09375), why does this one have the same limit even though it has 6 times the area?

I'm having trouble getting this sensor to register small touches. It registers if I squeeze the entire surface with a flat object, but not if I just squeeze a part of it with two fingers.

It basically works if I squeeze all of the surface, but it does not register if I only squeeze a small point on the surface really hard.

I'm using a 10k resistor. Should I drop that down? I'm using a pull down wiring setup as described in the first section of the guide.

Thoughts??

Curious if once calibrated at zero, 1/3,2/3 and full scale, do these devices hold as far as remaining consistent?

With low linearity, what was the application these were designed for?

Cioara from Betclic

These sensors look like the ones that are used in the Native Instruments maschine. Their version of the pads have a square hole in the middle for the leds and are working slightly different i think. But maybe it is a good idea if sparkfun (if it is possible) add similar square pads with a hole for leds?

here is a link to the NI Maschine teardown.

How do you solder onto these things? Is there another way to make connection with them?

hi all, how do you cover / mount this in your project usually? i mean, is it possible to put a plastic film on top of it (or something similar) ?

All your pressure/force sensors seem to be not "incredibly accurate".

I'm looking for a sensor that can register weights in the 50-300 grain range with an accuracy and repeatability of no less than 2 grains/10%.

That's what I would call "moderately accurate"... but I don't see any of those mentioned.

Did I just miss them? Or do you not stock them?

is this sensor flexible. Can it be bent?

From my experience, it can only be bent slightly.

Would this sensor register light "hits" such as hand drumming? Is the sensor flexible? Are there smaller versions? Would you recommend a different sensor if the project requires the sensor to register light "hits" with the fingers? Even a "forceful touch" should register (and later produce a sound).

Thanks in advance for your help!

Here is a video of how we used with an indian make of the arduino ! Also provided is the connection detail and the code.

http://tenettech.com/comet/?page_id=191

Or try a piece of conductive foam between two pieces of copper clad pcboard stock.

But this is much cleaner.

These work very well. I was able to hook them up to an Arduino with a simple voltage divider circuit (as suggested by the FSR integration guide), but I did not have to use an amplifier.

I wrote a simple script to send the pressure data via serial from the Arduino, and then used it in a Panda3D Python application.

They would probably not work for extremely accurate measurements, but I am able to control the pressure in the application with my fingertips quite well for my purposes.