Hot-air Rework Station - 303D

This hot-air rework station is great for professionals and hobbyists in need of tight temperature tolerances and large air flows. This unit displays a digital readout of the actual air temperature with a flow rate of up to 23L per minute. This very powerful unit can be used for multiple applications including standard SMD reflow/repair/removal, thermal IC stress testing, thermoplastic welding, and shrink-wrapping.

- 303D Hot Air Rework Station

- Wand Holder

- x2 Round Nozzle Tips

- Closed-loop temperature control

- Heats up quickly

- Anti-static design

- Intelligent cooling system maintains airflow after the unit is powered off until the air temperature is below 100°C

- Temperature adjustment range: 100 ~ 480°C

- Handle length (including air line): 120cm

- Noise: <40dB

- 110VAC input

- 224 x 126 x 110mm

Hot-air Rework Station - 303D Product Help and Resources

How to Use a Hot Air Rework Station

April 10, 2018

Hot-air stations or heat guns are very useful tools and are essential for any electronics workbench. When working with or building printed circuit boards, there is a lot of room for errors to be made. Have no fear though, there are ways to remedy this with a hot air rework station!

Low Airflow when "Air" Dial is Turned Up

If you are getting low airflow when the "Air" Dial is turned up, make sure that you have the nozzle securely attached. With the nozzle, you will get more air flowing through the hot air rework station's handle.

Nozzles

There should be two nozzles that come with the unit. One has a small diameter of about 4.08mm. The other should have a diameter of about 8mm.

Tips on using a Hot Air Rework Station

S-E and H-E errors

"S-E" Error

“S-E” usually means Sensor Error. It’s a common error. Sometimes it goes away after messing with the dial and the temperature will display properly again. Other times it indicates that the heat sensor is failing. The rework station might be able to be revived by removing and re-attaching the heater. Another tech support rep thinks it’s oxide building up on the connections. This results in fooling the controller into thinking the heater has failed.

"H-E" Error

Units displaying the “H-E” usually means there is a heating error. It might be that there is something with the heating element failing or not connected properly. Try checking the connections to see if the heating element needs to be re-seated. Last resort is getting a replacement heating element. A last resort is getting a replacement heating element.

Current draw for the 303D Hot-air Rework Station

The 303D needs about 4.75 amps at 120 volts AC to function. If you're using a voltage converting transformer to operate the 303D on 240 volt power, you will need a transformer that is rated for 600 watts or more. If you should happen to need to replace the fuse on your 303D, a 6.3 amp 250 volt fast blow fuse like one of these is what you should use.

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Competent - You will encounter surface mount components and basic SMD soldering techniques are required.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4.6 out of 5

Based on 57 ratings:

10 of 10 found this helpful:

Why didn't I get one of these sooner?!

I'm an experienced electronics hobbyist who's done lots of through-hole soldering, but relatively little SMD stuff. (I built a SoftRock RXTX transceiver -- which has quite a few SMD parts -- using only a soldering pencil. It was a huge pain.)

After spending an evening using the 303D to solder some practice kits, I'm a believer. It takes a little practice, but it's easy to use and produces great results. Surface tension and the solder mask do all the work for you.

Every tried to use a soldering pencil to connect an SMD part where some or all of the pads are completely underneath the part? Can't do it. With hot air, it's a snap.

Soldering an SOIC with lots of pads? Good luck not making bridges between adjacent pins with a pencil. With hot air, just smear a line of solder paste across the pads on the board, put the part someplace close to the right position, and heat things up. The solder mask will make the solder "bead" to just the places it should be, and the surface tension will actually pull the part into exactly the right position.

Need to desolder a surface mount IC with 40 pins, and still be able to use that IC when you're done? Hot air is the only way.

The 303D heats up fast, is easy to read and adjust, and runs quietly. (There is some fan noise on the higher air speeds.) Note that I haven't used any other hot air rework stations, so I can't compare it to others, but I'm super-happy with this purchase.

Watch the SparkFun video -- it's helpful. I found the "middle of the dial" air speed setting a little too fast; it was blowing my 0402 resistors all over the bench. [Edited to add: I was using the smaller of the two nozzles shipped with the unit. In the video, they were using the larger one. That's why I needed a lower air speed setting.]

If you're on the fence, and especially if you're struggling to solder SMD stuff with a pencil, jump on this. It's one of those "Where has this been all my life?" tools.

4 of 4 found this helpful:

Hasn't burned my house down yet

This thing is basically a magic wand that costs $115. You can wave it over an SMT component while barely tugging with a pair of tweezers and the component will come up, usually in reusable condition. You can do the reverse of that. You can make tiny grilled-cheese sandwiches. You can light cigars. I'm pretty sure that at 900 centigrade you can melt aluminum. Why pay more?

1 of 1 found this helpful:

I wish I had this 10 years ago

I started out soldering SMD with an iron. That was a nightmare of solder bridges and burning traces off of the board. After that I briefly experimented with the hot plate method that Sparkfun was advocating at the time, but found it too difficult to regulate the temperature and get a uniform heat transfer from the hot plate to the circuit board.

After that I moved on to the toaster oven and got good results by turning it on and off when it reached certain temperatures in a way that approximated the reflow profile provided by the solder paste manufacturer.

This product addresses certain issues that I ran into with the toaster oven method.

One is that it frees me from the need to populate the entire board before baking it. This can be a problem since I sometimes jostle a previously placed component while positioning another one, or cause things to become misaligned while sliding it into the oven.

Another issue is that the $30 toaster oven does not produce a uniform internal heat distribution, so some portions of the board become too hot in order for other areas to become hot enough. With this tool I can control the application of heat to each area and pull it back if it looks like something is getting too hot.

I recommend using the large nozzle for soldering and the small nozzle for de-soldering. The small nozzle produces enough pressure to blow away the solder paste. This is bad if you want the paste to stay in place and melt, but good for cleaning residual solder off the pins of a part that you intend to re-use.

Good luck in all that you do, Alexander W. MacFarlane IV Ph.D.

3 of 3 found this helpful:

Awesome

It purrs and pumps out regulated hot air. I can remove a single component on a surface mount board quickly and easily without disturbing the components around it. The temperature setting is digital and it reaches temperature quickly. I prefer an electric skillet for re-flowing a whole board, but I can re-flow with this in a pinch. Changing a resistor or capacitor value is a snap.

Without a nozzle it's great for heat-shrink tubing. I can set the temperature to activate the shrink without overheating things inside. I can use it in its stand so both hands are free.

It looks sharp too. I don't know how they make it for the price.

2 of 2 found this helpful:

Seriously the best $115 I ever spent

This thing just oozes quality. Other reviews cover everything you need to know. Just adding another voice to the choir. Make sure you watch the YouTube intro video.

2 of 2 found this helpful:

Simply great!

I just wanted to start working with SMD components and designs, but the hand-soldering smd process is a pain in the [censored].

I didn't wanted to spend my money on something cheap that simply doesn't work so I gave the 303D a try and I was surprised of the excelent quality and easy to use.

Now I want to work only with SMD components because this thing make its incredibly easy to do.

I recommend to get one of these is one of the best investments that you could made.

1 of 1 found this helpful:

Worth every penny

I've only used it a few times but it's already payed for itself.

In my stupidity I had forced a micro usb plug into a SMD micro usb jack and the extra force broke the jack off. Since I had the rework station and a cheap usb microscope, I decided to see if I could use the rework station to reattach the usb jack. It worked, and my $125 duet 3D printer board is working again. This station is worth every penny.

1 of 1 found this helpful:

Quite effective.

I have only used it once to remove a 16 lead TSSOP component I had soldered in backwards. It was easy to unsolder it and re-solder it in the correct way. I was able to reuse the component. For the price it was a bargain!

2 of 2 found this helpful:

Best thing I've ever owned

Thirty six years in the electronic repair & service industry! Been using Pyro-Pen all these years but this hot-Air machine is so great already paid for itself the first time I used it!!!!! Thank you Sparkfun. Mike Nab@ Mike's Electrnics.

1 of 1 found this helpful:

Great quality at a great price.

I have soldered SMD components using a soldering iron before, not really fun. So I decided to buy this station and now it is fun. The price is right, its features are right and it is really easy to use.

If you have not used hot air for soldering SMD, watch the videos on YouTube. It is really easy, you only have to watch for using the right amount of soldering paste, the right temperature and the right air flow.

1 of 1 found this helpful:

makes salvaging electronic components quick and easy

solder melts very quickly, air blows most of it from the joint so the components are usually clean enough to use without removing blobs of solder from leads.

1 of 1 found this helpful:

Great equipment

It is a wonderful equipment to rework boards of other devices.

1 of 1 found this helpful:

Glad I bought it!

I've wanted one of these for years but never committed to buying one. I finally did and I'm so glad I bought it! The build quality is excellent. It has some nice features like automatic cool down. It also comes up to temperature quickly and the controls are easy to use. It took some experimenting to find the best settings and skill to use, but I was eventually able to get all the parts I wanted desoldered from the board, and of course for 44 pin QFP surface mount chips that would be almost impossible to do with any other tool.

3 of 3 found this helpful:

Excellent Temperature Control

This hot-air rework station is one of the best I've used. The temperature control with digital readout is fantastic. I don't have to guess as much about whether or not I'll scorch the PCB.

2 of 2 found this helpful:

Great station

I've been using the Sparkfun Hot Air Rework Station for a few weeks and have been really enjoying it. I'm pretty sure it's just a Sparkfun branded Madell 850, which is good news. I used to work for a company which used 20 or so of the Madell stations all day every day for shrinking heatshrink and hot air rework. I was in charge of repairing them, and they were very sturdy machines. Mostly, the element would fail, after a few years, but that's to be expected. Occasionally you'd have an issue with the conductors breaking due to mechanical fatigue (where the wires enter the machine), but it was pretty rare.

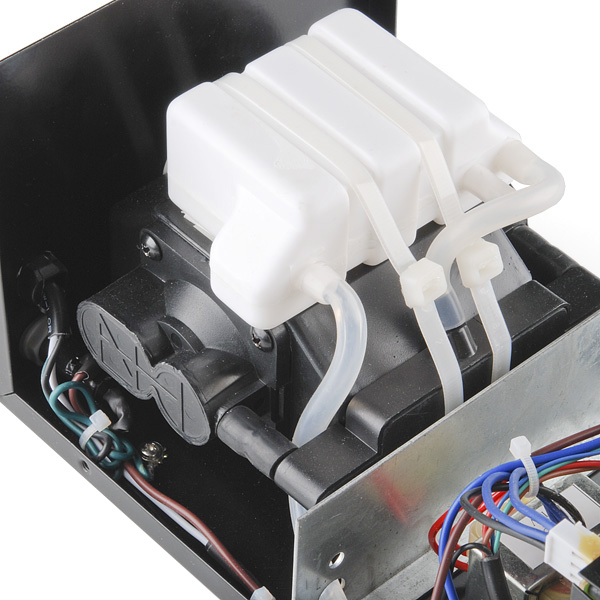

On arrival, I did have a bit of vibration noise coming from the machine. I opened it up and it was just a heavy gauge wire running to the pump, vibrating against the case. I zap-strapped the wire to a strap clamp and problem solved. That's part of the beauty of these machines, they're simple to work on.

Very happy with the hot air rework station. If you do SMT work or lots of work with heatshrink, this is the tool you need. Sturdy and well built.

2 of 3 found this helpful:

Most valuable tool in the lab!

These rework stations continue to perform day after day and have not let us down in the 14 months since we purchased the first one. We just bought the second station, and already have it working overtime.

1 of 2 found this helpful:

Works well, received it broken

The small nozzle was broken when received.

Hi, We'll help get you a working nozzle. I'm going to send you a private email to work this out with you. Thanks

Out of the Box It Worked

I have only used this piece of gear once since I bought it. I'm new to SMT repair, but this unit seems to work as advertised. A smaller nozzle than what is supplied would be a good addition to the product's included components.

Other than that, I dialed up a temp to remove a small SMT resistor and that worked perfectly. Takes a bit of adjustment to set the air flow and temperature, but not hard to figure our. A nice sister product would be a small hot air blower for the bottom of the PCB for preheating the bottom of the PCB.

Quality looks good, seems well made. I'm sure I will get a lot of use from this items as time goes on.

I meant to give this review 5-Stars, but submitted it before I selected the 5th star.

Bob J.

Well designed tool

Temperature comes up very fast and shuts down almost as quickly. Setting for temperature and speed of air appropriate for removing and replacing small surface mount components. No more Solder Wick and Exacto-Knife prying pin by pin.

Great product

This is my first rework station and it gets the job done well. It has a sturdy exterior and works great. Highly recommend for anyone looking for an affordable rework station.

It gets hot, then it blows

Works great. It will even store back in the box with the holder attached to it! (It ships with the holder unmounted.)

0 of 1 found this helpful:

Rework Station 303D

I don't yet know how well it works. I have not used it, plan to do so soon. Will let you know what happens.

Thanks

Why did I wait to get this tool?

I had no idea how much of a difference having this machine could make to my enjoyment of electronics as a hobby. Today most of the new interesting parts are SMD with .5mm lead spacing. Nothing that I would attempt with a soldering iron. My first 8 uses of the 303D were total successes(mostly .5mm devices). I did have to use solder wick for some touch up.t I can now use breakout boards for new SMD devices to try them out before thinking about going to a PCB design. Best tool I ever bought.

Works like magic

Superb way to recover parts and to make new board.

0 of 1 found this helpful:

Nice tool

The station arrived in good shape and within acceptable time. The station worked as advertised and seems to hold it's temperature. I was able to remove and replace SMDs with no problems and no overheating.

0 of 1 found this helpful:

works great

Does what it says on the box. Had no issues using it. fixed a few things with it already.

Works Well

I haven't owned another rework station, but from my limited time with it, it works really well for what I need to do. If I had to say anything negative, it would be that the air-tube is a little short for my workstation. Another 6 inches and it would have been perfect for me.

Really nice hot-air rework station

We tried one of these where I work and I liked it so much I bought one for home.

It's quiet, fast, simple to work and very responsive. You can set the air-flow exactly as you need it for perfect re-flow without blowing parts off the board. It doesn't take up much space so it's convenient to have it on the bench. I actually use it for more than re-work. It's also great for the occasional heat-shrink job and drying stuff.

It seems many of the off-the-shelf nozzles fit if you feel the need for other shapes.

You simply can't beat the deal if you want the simplicity along with a good display.

Works great, amazing deal.

Well built at a glance. Heats up fast, does the job. Amazing price.

Move over Harbor Freight latex tape measure, momma has a new favorite tool!

Seriously - this has become my go-to tool for just about all IC removal tasks. With a little practice and some skill you won't often need to change the tips for different package sizes. Also great to have one tool on my bench for heat-shrink, welding plastics, and hot air solder work.

Excellent quality typical of products vetted and distributed by Sparkfun. Has adequate cool down time and parts are easy to swap should the unthinkable happen.

It takes about 45 seconds on high to pop a single kernel if popcorn - if you can keep it from blowing away.

4/5 because air flow doesn't go any lower then A25

This is a great hot air tool. But like every brand it has it's downside. At A25 this unit will blow parts off the board still if your not careful with it. Other units I own have a much finer control of Air and allow you to dial it down to almost nothing for working with 0201 parts and 01005 parts. I would not recommend this hot air for parts under 0805 but I have used it with success on 0603. If it had more air control or a greater range of air control I'd give it a 5/5.

Great for the price

I just used it to remove 20 pin through hole header and was surprised it worked. Also great when I want to soften and bend acrylic or activate heat shrink. I tried to remove a solid state relay that had a 15mm x 15mm solder down heat sink and I was not successful after 20 minutes of heating. Professional units are priced 5-20 times the cost of this unit so this is an amazing value.

Out of the box I like thing.

Out of the box I like thing. I teach building trades apprentices soldering, brazing and welding. This thing is a hot air torch, not nearly as hot as an oxy acetylene flame. There is a learning curve involved. Do some practice before you cook your expensive parts. Be prepared to destroy a couple of things before getting the hang of heat management.

The temperature and airflow are nicely adjustable.

Good but short-lived

Hi! Bought this device one year ago and it just broke. I have used it three times, in total less than an hour. Seems like the fan gave up. Rather bad smell. Otherwise very happey with sparkfun products I have.

Kind regards /Carl Fredrik Leanderson

Fits my needs to reworking boards

The adjustable heat and fan levels work well with this unit. The digital read out display is a nice feature. Still trying to figure out the optimal temperature and fan rates with reflow solder. Very good quality for the money!

This thing is really helpful for removing 100 pin QFP chips, well worth the price

I bought this to remove PIC32 QFPs that occasionally have technical difficulties while in my care. This thing works great, I really don't know how I lived without it. I have tried using it to solder down parts with pads underneath them, mainly 4 pad oscillator chips and it works for that as well. Whenever I try that though it makes me a bit uncomfortable not being able to see if I melted all the solder. Also have trouble getting the solder paste to stick to the pad, it always wants to come up on the syringe, anyone have any helpful hints? I gave it 4 stars, would have given it 5 if there was some built in holder for the unused nozzle. Currently storing the nozzle in a drawer, if I ever need the larger nozzle I am likely to forget where I put it.

Glad you're enjoying the Rework Station! Regarding the solder paste, I talked with one of our guys in Production, and he said that, when possible, he'll apply the past to the component, rather than the board. If that's not possible, he'll apply a think bead, and then remove the excess with an iron afterwards. Hope that helps. Happy hacking!

As Advertized

This is a good rework station. For a hot air station it is not suitable for solder reflow for small components because it blows them off the board when the solder melts. I guess one would expect this though since it is advertised as a rework not reflow station.

Smooth heating action

I don't know if you have ever tried one of those soldering hot air stations where the blower is in the handle. I have and they remotely work, but not well. For some reason, having the blower in the machine and sending air through the tube into a heating element is superior. I had a very similar soldering station at my desk at work and I never knew how good it was until I had to trade it in for a cheaper station with the blower in the handle. Originally I had no problems reworking SOIC and SMD components but when I changed to the cheaper station, I could only rework SMD such as resistors and capacitors. I had a difficult time with SOIC parts. And don't get me started on voltage regulators. Impossible. So when I wanted a personal soldering station, I opted for this one. It was a little more money than I wanted to pay but the soldering quality is outstanding. The digital temperature readout is phenomenal. It's quick to react and the cool down period after the power shuts off is wonderful. I am quite impressed with this device and have no problems desoldering large components. If you are debating on whether you should spend $50 for a cheaper soldering station, then stop. Buy this one. As far as soldering is concerned, you will not regret it.

Too busy to try!

But I did give it a close look and the build quality is good. I powered it up and it sure looks impressive. I'm going to give it a good workout over the holidays.

Good rework station for my needs

This rework station is just that, it is great for repairs and some light assembly or bare board soldering. The adjustable air flow is very convenient for new work.

Great so far.

This is my first rework station. Looking around, they can be very expensive. Because it had sparkfun's name on it, I decided to get it. It seems of good quality. It's pushing hot air! I've used it to remove a few pieces. It also does shrink wraps so much better than a hairdryer!

I like this one better than the ones at work.

I use to have to drive into work when I needed to do Hot-air work on the weekend. It gets plenty hot. With the digital display it is easy to get the same temperature again.

My only complaint is that it does not turn up the fan speed when cooling down. That is why only 4/5.

Pro tip: When soldering a QFN part, tin the pads on the part first and use flux. If you're the one laying out the board, make the pads stick out from under QFN parts so you can get the heat under it.

It blows hot air!

So far so good. Everything is working great. Have done some desoldering and small surface mount soldering with it.

Satisfied

Works as expected. Works fine using a 300W 220V -> 110V converter.

Very Nice Feel and Operation

I looked at what was available in Hot Air rework stations, some were a low price but of questionable quality. I came a across the Spark Fun 303D and watched the video. The folks at Spark Fun did great job in sourcing this machine. It works a feels like you would find in a top end PACE. What can I say, it works very well and you wont be sorry to buy one. Thanks Spark Fun!

Revolutionizes my soldering (and desoldering)

For many, many years I've been successful with traditional soldering irons. Lately, though, I've gotten involved with surface-mount components and more ambitious desoldering/rework and have struggled a bit. I decided to give hot-air a try and took a chance on the SparkFun 303D thanks to the other positive reviews and the reasonable price. I've just completed my first project (removing a SMT crystal to repair my STEMTera board) and it was flawlessly easy. I'm impressed with the relative precision, overall effectiveness, and sturdy packaging of the 303D. I have more SMT projects in mind and am looking forward to them now that I have such a great tool on my workbench. Definitely recommended.

WOW!!

I cant believe the quality of this tool for 114.00!!!!!!! great piece of equipment Thanks Sparkfun.

Excellent machine especially for the price!

I was a little dubious of the effectiveness of the machine, but I figured I'd give it a try for a project and was pleasantly surprised. I was able to quickly and easily replace a couple chips on an expensive circuit board.

A Valuable tool

I haven't used it a lot yet, but it has been a tool of excellent quality so far. Since this is my first foray into hot air work, there is a bit of a learning curve. Rather than head right into it, I've been learning a lot by taking old pcb's and playing around with them.

Awesome tool!

Easy to use, easy to setup, and excellent results.

I am really happy with this Hot air rework station. It's probably one of my favourite tools in the arsenal.

I've built a few SMD prototype boards using it. QFPN-100 chips I am using soldered and removed without issues. As well as all the other "jelly bean" SMD components. It's perfect for prototype work and it has also retired my heat gun for shrink tubing.

The build quality seems great as well. All tools should be like this! Single purpose, simple to use and no frills. Would buy again definitely.

Like using a magic desoldering wand

Solidly built, extremely fast to get up to temperature, precise temp and airflow adjustment, nice comfortable grip, kink resistant hose, replaceable element. Love it!

Works well

It quickly heats up, the controls work well, and it doesn't take long to cool off when I turn it off. The attachment for holding the hot end is convenient. Only complaint is that it only comes with the two nozzles. It would have been nice to include a few more with it.

0 of 1 found this helpful:

Great tool for the price!

Best $100 I have spent on a rework tool!

Does anyone know how to change the display from Celsius to Fahrenheit?

Love this product, used it extensively for 2 years. However, it just started acting up, it won't power off properly. I switched it off and nothing happened; in normal use, it'll stay on for a long enough to cool so it can shut the air down safely, but for whatever reason now it just keeps heating. Ended up having to unplug, plug back in (still didn't fix the issue), then set the temp to 100, then pull the plug when it hit 100. Weird. Anyone else seen this?

This looks like a rebadged Atten AT852D unit. If so, its actually a good price on this, so long as Sparkfun inspect each unit. The QA on these Chinese units is abysmal.

I asked via chat and was told that SparkFun's supplier for this station is indeed Atten Instruments.

Is this product discontinued or will it be restocked?

Am I the only one who sees the irony of a device for SMT rework being made entirely of through-hole parts?

This works very well for hobby work as well. Brass locomotives, sheet brass soldering, plastic bending etc.

So Cool

I need a bigger workbench.

Your workbench will never be the same. I cannot say enough good things about hot-air rework. These things rock and open up a bunch of new doors for prototyping (removing ICs, SMD IC bumping, etc). It's a cool tool.

You mean it's a hot tool?

agreed. as i said in the product post, i reflowed my nvidia BGA video processor in my laptop with one of these just last weekend... worked like a charm. you can do almost anything with these.

Which chip was it? I've got a Lenovo T61 with the Nvidia NVS chip (8400 gs). It has experienced the intermittent failure. I was looking at using the heat gun you folks sell to try a reflow. Do you think this hot air station would do a significantly better job? Thanks.

I also have Lenovo T61 but graphic is Intel Corporation Mobile GM965/GL960 Integrated Graphics Controller. I was wondering if it would be possible to exchange it for something more powerful ? Probably not. Anyway hot air station is nice but 110V and probably US plug ;)

I know its an old thread but I've recently had success with the T61 Nvidia issue by stripping the MB and placing it in the oven at 380F for 10min. I've seen others have success with this for other MBs, graphics cards, etc..

I think it was a 7600 something. Honestly, any kind of heat works. I've seen it done with hair dryers, blow torches, etc. All it needs is heat. The hot air rework is a lot easier, but you could use a hair dryer or the heaterizer...

Can you guys do a video showing how you do BGA? I've got an older one of these from you guys & would love to be able to place/solder BGA chips (since they're usually the coolest ones), but am a bit unsure how to start.

that's a tough one. it 'can' be done with a normal hot-air station, but it takes a LOT of practice to get it right. the correct way is with a BGA rework station.

I just evenly heated the chip with a hot-air station, let it cool a bit, heated a bit more, let it cool, heated it a bit more, etc. and it worked.

if you're starting with a bare board and populating a BGA, it can be a lot harder. flux helps, but can also be really difficult to rinse out.

A very nice unit.

I decided to get this one after using the stations we have here at work. (different brand) This one is every bit as good. A little large, but for what it does, it would be hard for it to be small. You will definitely want to practice on some scrap boards first, as it is very easy to get it too hot and delaminate your PCB! Once dialled in it is just like magic.

It sits next to my metcal, and I think it's every bit as useful. :)

I want to buy this Hot-air Rework Station, but the day off, they have been all that remained, there is a date when you can buy this product?

I have the same question, but with the words rearranged somewhat.

This is a very nice tool and a good multitasker - well worth the space it takes up on your workbench. I bought the 303D 4 months ago to do SMT rework and I've done a little of that but it is also fantastic for heat shrink tubing and re-melting hot melt glue. I think I'll try toasting marshmallows with it next. Cheers, Jay.

I've had this on backorder for quite awhile. What's the ETA? I really don't want to have to order it from somewhere else...

Second.

Just the right price point for 2012 Free Day!

I agree! Just picked one up ;-)

What is the power consumption at 120VAC ? I need one for 230VAC so will need to run it from a drop down transformer.

Same here - the element is 250W, plus the control systems, pump and efficiency factor, I think it will be just over 300W.

I think 500W will be plenty - so I'm going to use http://www.maplin.co.uk/p/tacima-110v-to-230v-500w-voltage-converter-n59hf - there is a much cheaper 300W unit from Maplin too, but I worry that will be too close to the unit demands and I'd rather supply the 303D with the supply it deserves.

Is it feasible to use your Hot Air Rework Station 303D to weld plastics?

I have just now with this unit "repaired" a threaded plastic ring from a shower head ball joint, which split in half (axially) this morning. I kept airflow at 1 and turned it down to 320C to avoid browning and bubbling, and since the ring is several mm thick, I have no idea how deep into the seam it actually melted. I didn't want to work from the inside because the threads wouldn't have made it. So, it looks like crap and may snap again soon, and I might have saved around $6. Try it! (on something that's trash anyway)

I'd imagine if you were to fashion a tip to get the width of delivered hot air down, you could melt plastic together - but you might be better served using a plastic epoxy or CA glues that will melt the types of plastic your looking to join. Saving that, the 'sacrificial soldering iron' idea seems solid.

Freaky question, I like it. I would say probably not. The width of air coming from the nozzle is good for ICs and PCBs, but may be too wide for joint welds. I'm not entirely sure what you're doing, but if I was doing something like multi-unit construction, I would buy a soldering iron and sacrifice the tip and heater to the welding. Tell us more if you try it out.

Getting this in October for sure! Will go nicely with my Sparkfun soldering station.

Yea I need one of these for that exact reason... as well as SMD work

I'd realy like to have one but on the countent despite we are using other plugs, we use 230 V +/- 10% and 50 Hz. https://de.wikipedia.org/wiki/Netzspannung/medi/File:Weltkarte_der_Netzspannungen_und_Netzfrequenzen.svg

Can be anything done to get it working in Europe(by whome soever)?

Just unboxed this... seems to work properly but am surprised at the easily-audible hum the unit produces. Does everyone else experience this? Thanks

does anyone knows the power transformer specs ?

ANYONE KNOWS AMPS FROM THE POWER TRANSFORMER ?

I'm using this in the UK / EU on 230V so I need to know too...

The element is rated at 250W, plus the control systems, pump and efficiency factor, I think it will be just over 300W.

I think 500W will be plenty - so I'm going to use http://www.maplin.co.uk/p/tacima-110v-to-230v-500w-voltage-converter-n59hf - there is a much cheaper 300W unit from Maplin too, but I worry that will be too close to the unit demands and I'd rather supply the 303D with the supply it deserves.

If you know of a decent AC-AC converter for 500W that looks nicer and costs less, please let me know as I need a few of these things!

This is seriously the best electronics purchase I've made to date.

I bought this product a couple of months ago. I have to admit, I didn't expect much from a hot air station that's nearly a quarter the price of name-brand stations. This product has blown me away. I have used it to remove components from boards for reuse and also for assembling boards that I had printed. It has worked far beyond what I expected. The temp setting is pretty accurate (to within a few degrees C) and the airflow setting gives perfect control. I have recommended this tool to a few friends who also agree that for the money, you cannot go wrong.

At my school we had same like these at 230VAC (Xytronic 850D ) ones and they had habit of burninc Triacs that drive the Vaccuum pump. Those units came installed on TEKLAB workshop solutions. These are easy to repair almoust every time. The transformer was something like 240VAC--30VAC if i remember right... I think the internal transformer wouldnt be much to change to 230VAC version, but i think ill pass this device and by Xytronic one.

Far out.

Indicated dimensions (224 x 126 x 110mm) are not right. I just got this guy and the dimensions of the case are 245mm d x 158mm w x 138mm h, not including the handle on the top (31mm ) (or the knobs, etc).

Hi. That station will operate on a 127VAC power line?

Thanks.

I'll be honest, this thing scares the crap out of me. As much as I so badly want one, I think I'd melt my finger if I had one. :P

Has anyone modified to switch display from Celsius to Fahrenheit?

Could I use This With 220 VAC? If yes, I Think I Will Buy This One.

Well, I will just buy an 220 to 110 adapter and it should work!!

Nope. You could replace the transformer block, though.

I just got one of these. Thanks for making it well and also affordable.

I received mine with a defective fuse holder... at an hundred bucks.. I cant really complain... Anyway,I replaced it and now it works fine!

This is also the perfect tool for precision melting of crayons!

Mine died after sitting in a closet for a year. Anyone have experience repairing these? For a while I had to slap the case to make the temperature display turn on, and the air heat up. But now no matter what I do, I just get cold air blowing out, with nothing on the temperature display. Sounds like a loose connection or bad solder joint somewhere, but where?

open the case and verify that the Microchip MCU is stil in the socket... It is a cheap socket and in vertical position. Slapping the case can only make it worse lol...

I got a problem with the outer hose.. is there a replacement part for this?

Contact techsupport@sparkfun.com and they should be able to assist you further.

I just received one of these hot air rework stations and I had been putting off buying one for a while. I now realize that was a colossal mistake! The auto cooldown feature is awesome and the controls are spot on. I really don't know how I did without this tool as I can throw away the junky harbor freight heat gun and quit borrowing my buddy's plastic welder!

This is the best tool i have ever purchased ... Its like magic make sure you get the sparkfun tweezers too and some helping hands. It is so nice to be able to control the temp of air that touches the part. Keep the warping down.. Thaks sparkfun!

There is an Europe version ( can work with 220 V ) for this ?

There are 220V hot air rework stations, but SFE doesn't carry them.

However, if you're endeared to this particular product, and don't necessarily want to shop around for a 220V version closer to you, see JRad's comment on how to convert this product for 220V use. You could also try a 220V to 110v converter, but those can get pretty expensive.

If you did want to get this, now would be a good time (for you) to do so, since shipping is free this week (and this being a heavy product, it tends to be pricey to ship - another reason they generally don't carry 220V versions of these types of products).

Is this capable of handling 220-240v mains input voltage, or is it strictly 110v? It would be good to have a European version!

Amazing tool. It works well both to remove and solder parts. Great for recovering parts from old projects. Its easy to use and well built. Great value for money. I can't imagine how I managed before!

Is there a 240v version, for Europe?

A 230V variant which is pretty similar (I think same OEM, these things are re-branded) is available as ZD939L in Europe from several sources for about the same price. One that ships cheaply to CH, DE an other European destinations is www.reichelt.de

(Hope it is o.k. to post a link to a competitor, as you do not offer the 230V version and shipping your unit to Europe is really expensive...)

Any Idea when this will be back in stock or recommendations for similar rework stations?

I must say, Got this guys in the mail today and quite frankly haven't been this excited about a tool since getting my O-scope! I have been desoldering components from several reclaimed boards. Now time to start sorting caps, resistors, ic's, inductors, etc, etc. Really happy, Thanks Sparkfun!

I bought this almost a year ago and I do not regret it. This is such a great piece of equipment. After several circuits for work and personal I now prefer to use surface mount on all of my projects. Get some good paste! I prefer water soluble flux in my paste, then I clean the board in the sonic-cleaner at work. Though IPA can do the trick quickly with most water solubles.

Just read all the comments, saw the question asked, but no answer...will this unit work with the Aoyue nozzles? Thanks!

This can work directly on 240V!! (try at your own risk, and ONLY attempt this if you're experienced)

I reverse engineered the circuit, and found that most of the components should be able to handle 240V. Here's the mains side of the circuit:

Schematic

The modifications required are circled in red. Basically all you need to do is swap out the transformer!

First I carefully measured the circuit on 240V using a 100W incandescent light bulb to limit the current. All the voltages checked out, and nothing got hot or burnt. I then removed the light bulb, and checked that the station operated correctly.

The heater element heats up extremely quickly, but since it's temperature controlled, the higher voltage doesn't seem to matter. However you must make sure the pump air speed isn't turned above half power. There is a trimmer pot that sets the minimum airflow, so that needs to be turned down.

Proof it works:

Photo 1

Photo 2

Please remember mains voltage is lethal! Try this at your own risk, and be aware doing this could burn down your house, etc etc. Also since the circuit wasn't designed for 240V, there's no guarantee it won't blow up eventually

Is this thing really a Sparkfun design or is it someone elses Hot Air Station with the Sparkfun logo on it?

so i can't use in in europe in 230V AC ?

Not without a converter. For this product you could try swapping out the transformer inside, though. Would save you the converter - which you can't even begin shopping around for without knowing the rated wattage for this station :)

Just rcved this, Here is a short review:

It is a good tool for basic rework stuff. Heats quickly, cools very slowly. Already fixed a module (work $20) with fine pitch QFP that no amount of soldering iron/wick would fix, this thing will pay for itself in no time.

My desk is full already but the tubing on this unit is long enough to put it in a far corner and still be usable.

One con: The temp display is cheap and only fully visible from an angle (maybe it is just my unit?).

Looking to buy one of these but what do you guys use to protect the work desk from the heat?

Asbestos?

Seriously though, when I do rework, it's typically held in a third-hand of some sort to raise it off the work surface. You could also use a trivet, silicone pad, oven mitt, or other item from the kitchen designed for high-temperature use (don't re-use it for food though!)

I'm looking at these but am also worried about the heat due to a special whiteboard paint on my desktop surface that is pretty expensive and I'm not sure how it will handle heat.

The asbestos comment reminded me though of something I already have. Ceramic honeycomb blocks, they're used to protect the work surface while soldering jewelry. Worth a look if you're really worried about your work surface.

How well does this work with QFN parts. Anyone with experience?

Now if I remove an ic "44 pin" using this hot air will the ic pretty much be shot from over heating?

Personally, I find ICs very robust temperature-wise, and so think that your chip would probably be fine(as long as it is not running while desoldering).

is there a 220 volt model available.

No, but there is an option to use 110 appliances on a 220 circuit. You need this transformer. http://www.amazon.com/Voltage-Converter-From-220-240/dp/B001ES8YY6 It's 18 dollars and it should work for this.

Just used one of these to reflow a 10 lead 3x5mm DFN and I was able to solve a short in about 30 minutes. Not bad for the first time using this tool, as it has basically paid for itself in the first use.

Just got mine today, yea... I should have invested in one of these a LONG time ago.

Just got this today, and for the price I couldn't be happier. I was afraid that I would be disappointed with the build quality (as I have been with several tools that SparkFun sells), but honestly I think it's just about where it should be. The readout is nice, the knobs work, it comes up to temperature pretty quickly.

A word of warning though!

The temperature control on this station is not the most sophisticated. I tested the output temperature with a thermocouple and at steady state it seems to hold the temperature to within 10-20 degrees of the setpoint: Good enough as far as I'm concerned though I wouldn't call it "tight tolerance." The real issue is that the controller has a tendency to DRASTICALLY overshoot the setpoint as it comes up to temperature. By up to or over 100 degrees! So if you are going from, say, 150 to 250, the temperature might briefly go as high as 350. Only for perhaps a few seconds before the controller catches up and brings it down, but long enough to damage components if you are not patient. There is the same behavior to a lesser degree when moving to a lower temperature.

Again it is not an issue as long as you wait maybe 15 seconds after changing the temperature before using it - assuming what you are doing is temperature critical.

Otherwise it looks like a great tool! I am excited to have it on my bench. :D

I just got this thing. I stuck a few magnets on there to hold my other nozzles.

Any idea when this will be back in stock?

Just used my Hot Rework Station(303D) for the first time and I must say this tool is AWESOME! Very quite, good size temp display. Also like the automatic cooling after shut down. This opens a new world for me.

I have a newbie general question regarding Hot Air Rework. I have recently bought this Hot Air Rework station to be able to bump ICs and remove them, etc. My question is how do semiconductors not burn out or fry under the heat? granted you are not applying heat directly to the chip, but I have always been told with conventional soldering not to keep the iron on a pin for any longer then you have to in order to protect the part. With applying 'solder melting' level of heat to all pins wouldn't that be a problem? I ask this, but I also must admit that I have been doing some work with this unit and have not had any of these issues as of yet. I just am wondering how concerned I should be about this.

The IC package is built to be able to dissipate a good ammount of heat. Think about in a production environment where ICs are attached to boards in a reflow oven! While this is the case, it is still important to subject the component to the smallest amount of heat needed to accomplish the task. This is why a variable tempurature rework station is important! Consult your data sheet and set the tempurature accordingly. Working with hot air does require a bit of technique, which you will acquire over time. Practice on scrap boards and expect to fry a few chips along the way.

Where would one procure nozzles for this, do Aoyue nozzles fit?

Here you go: http://www.sparkfun.com/categories/48

I'm aware of those, I was referring to sizes and shapes that SF does not stock.

Any idea when these will be back in stock?

Are there any oils or other gases (from heated plastics, resistors etc) that could come out with the hot air? Is the hot air (other than the obvious temperature issue) safe to breath?

There are tons of variations on the market, but two main types - The type using a Diaphragm pump like this one (been around longer), the other type using a brushless motor in the handle itself.

Has anybody tried both and any advantages / disadvantages?

Anyone have a good tutorial for how to solder SMD parts using this hot air station? Do you just point the nozzle at the part and go, or is it necessary to use another heater to preheat the board first, and follow a specific heating/cooling profile? Also can I get away with pre-tinning the pads with normal solder, instead of solder paste? The paste seems like a pain in the butt since it needs to be kept refrigerated, and I don't want to keep it in the kitchen with my dinner, or pay distributors extra money to overnight ship it in a cool pack.

I would like to know about the pretinning instead of paste like he said ^^^

The advantage to paste is that it's... a paste. Which means that it allows the part to sit level on the pads. You can pre-tin the pads with an iron and a touch of solder but if you have a tight-pitched part it may not want to sit on top of all of the little solder bumps the right way. It can be done for parts that have a small lead count. I solder ATMega328s by pre-tinning the pads with an iron then heating the pads in a circular motion with the hot-air while placing the IC with tweezers.

Just got this thing and it is great! I 'ocasionally' make errors when soldering parts onto boards and removing them with a soldering iron and solder wick is a pain and if its an IC its usually not even worth attempting. I just powered this baby up and removed about 10 parts in 2 minutes including a 48 pin LQFP which I never would have even attempted before. Oh - btw, it also melts desk protectors nicely. :)

This looks like a rebagged Aoyue 850A, only more expensive. Is this some other variety that is actually any better?

Nah, if anything it is a rebadged Yihua YH-850AD. But, Sparkfun has it at a great price, so why not get the one that says SparkFun on it and support these guys! :)

Correct me if I'm wrong, but the Aoyue 850A has no digital readout.

Do you know the VA rating?

At my school we have a hot air rework station. (Zefertronix i think) We have used to fix our ESC's to Xbox 360's (and build or robot communication boards now and then for our robots)

No airflow meter on this one like the Aoyue 852 you had before... :(

I have a 968 with a airflow meter, and I never use the meter. Just turn it up to where it's working for you. I can usually tell just by how it sounds.

What about the temp meter, do you use that or is it the same deal as the airflow meter - i.e. you just set it based on how it's working?

Now I have to convince my boss that we need for our lab. Shouldn't be too hard. :)

I am not kidding you, you need one for you lab. These are amazing. Tell your boss some random guy on the internet said so.

But really, we got one at work, and then I got one at home because it was so awesome. I use it for soldering even when I could use an iron. Its 10x better for so many things.

"Break" something that needs hot air to fix.

(*it helps if the broken item costs more to replace than a Benjamin.)

:)

Does this replace the other Hot-Air rework station? the HR906? Dang, I liked the combo hot air/soldering iron...

Just get an Aoyue 968 station from Amazon or some other site.

Yes. This will be the only hot-air station we carry.

Not even something for the rest of the world, which has 220V?

Only if there was a 220VAC version...

Ive always wondered why people who need a 220vac version when you can just use a converter. Is there a reason? They don't cost all that much.

You could use a transformer, but higher wattage ones do cost about the same as this whole product, at least in country I live in.

so how much current does it need? Makes looking for a converter a lot easier, and hopefully cheaper. I'd be keen for a 240 volt but a convert if its cheap is an option.

That box is amazing.

there's even an RTFM sticker on the bottom. pure class.