Robotic Claw - MKII

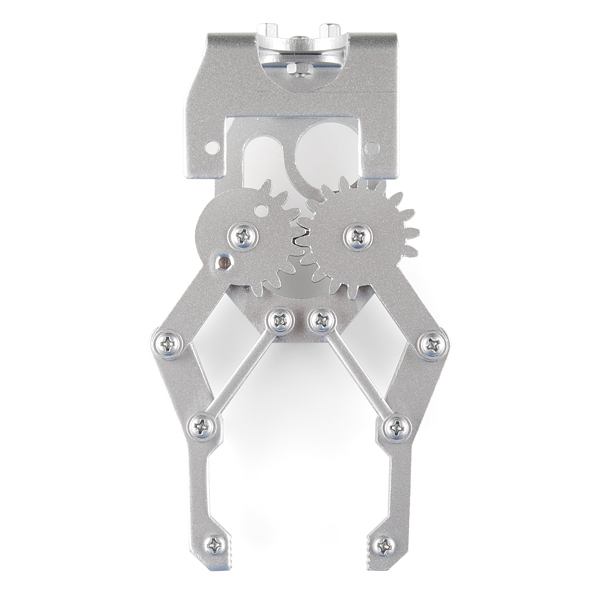

This robotic claw is a step up from the classic. The MKII takes everything you loved about the standard robot claw from DAGU and makes some significant improvements!

Just like the classic claw, they are made from metal and are pretty heavy-duty, but the MKII also features brass sleeves in the joints which make them more rigid and less likely to come loose. The claw opens to about 2" and depending on the servo motor used, it can pick up some relatively heavy objects. The new spring-loaded clutch helps protect your servo gears from damage and also increases the gearing to 2:1, allowing the servo to act over its entire range and provide more gripping power!

These also have a mounting plate on the bottom which accepts standard spacing found on servo mounts (the extra bits that come with our servo motors). These do not come with a servo motor, so check below, the 'micro servo' is the one that works well.

Replaces:ROB-10332

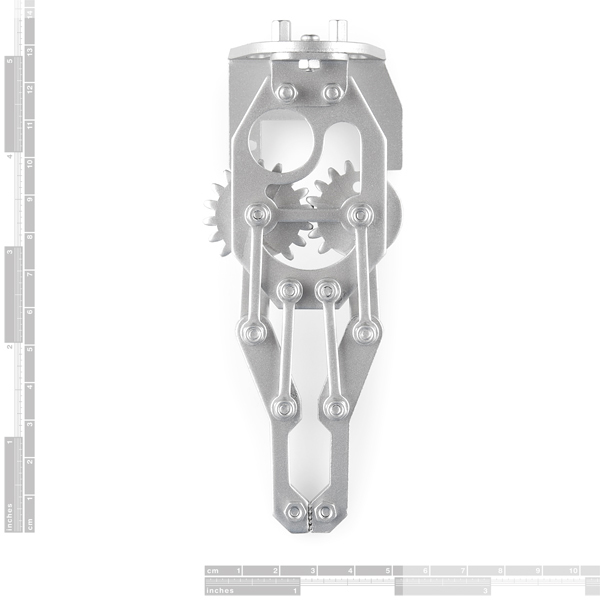

- Dimensional Drawing

- Assembly Diagram

- Assembly Instructions (Large File)

Robotic Claw - MKII Product Help and Resources

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Noob - You will be required to put together a robotics kit. Necessary parts are included and steps will be easy to follow. You also might encounter basic robotics components like bearings, mounts, or other hardware and need a general idea of how it goes together.

See all skill levels

Core Skill: DIY

Whether it's for assembling a kit, hacking an enclosure, or creating your own parts; the DIY skill is all about knowing how to use tools and the techniques associated with them.

Skill Level: Noob - Basic assembly is required. You may need to provide your own basic tools like a screwdriver, hammer or scissors. Power tools or custom parts are not required. Instructions will be included and easy to follow. Sewing may be required, but only with included patterns.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

3.8 out of 5

Based on 4 ratings:

1 of 1 found this helpful:

Worth the money

This is a pretty good mechanical gripper. It's made of stamped aluminum and weighs about 6 ounces (.17 kg) with the recommended-sized servo. The clutch is a nice feature - it reduces the chance of damage to the servo but also limits the gripping power. It's a little difficult to insert the servo and clutch without some disassembly, but can be done.

Yes, the linkage is a little loose and it's not extremely robust, but it wouldn't cost twelve bucks if it was something that C3PO would be proud to own.

I like it

My son and I are building a robot in slow steps, dictated by what we think would be cool at the time. We thought a claw would be cool, so we got this one. It was easy to put together and works well, except for a slight unevenness in the operation; the gears are slightly irregular at one point. It seems pretty sturdy, at least for the things we would like to do, and we'll have fun writing programs for it. For hobbyists, it's great.

Working so far, gets the job done

A team project for my university needed a robotic gripper from our own budget. This model was relatively inexpensive and the clutch is a big benefit compared to other options at the low range. It is a great claw for the price and meets everything we need. Just be warned that it may take a couple tries to get the clutch set properly (the magnets in it can stop the whole device if not set properly), but it has been working great since.

Having trouble hooking up the servo

Seems like one of the stronger options available, but I didn't read the description close enough and bought a standard sized servo. My mistake. I went to the hobby store and bought a Hitec HS-85BB micro servo. The horn uses a different screw, so I had to drill and tap it to get it to work.

I would remind any nay-sayers that you get a wonderful Claw for $11.95 + shipping. It does have quirks and flaws, yes. It's twelve by-blessed dollars - WOW! A little file work on the edges helps, maybe you have one that needs the clutch spline drilled slightly or to be used on a plastic shaft, little bodging about, yes yes, it happens...

But it's $12! $12!! You can use a $3 servo with it or an $11 servo. A cool, robotic claw! No, it's not perfect but, my happy-dancing-dog, you can have a WORKING ROBOTIC CLAW for less than tickets and popcorn for two at the movies!!! How is that not just WonDerFuL?!?!

The world is not perfect, and the MK-II Claw could be cited as proof of that - or, or, you could say "Pretty damned close!! I'll just apply a little finesse and get this dialed in! Hone my mechanical fitting skills, I will! What a great opportunity to SHINE!"

I'm 53 and you have before you now all the marvelous things I could only dream of as a child and for most of my adult life - don't let the little hiccups sour the wonder of it all, yeah? And, we should all be thankful for those folks out there that make these lovely bits and pieces of our dreams for us - because the alternative is to jigsaw the parts out of ply or plastic and really really have to fiddle it - been there, done that, learned lots, loved it but wouldn't wish it on a friend although I may teach it to my granddaughter. So! Chins way up! Eyes on the prize!

Would any of the Hitec sevos work with this claw?

we haven't tried it, but this one looks to be about the right size.

As I mentioned in another comment below, we first tried using ROB-11887, which fit the clutch and claw, although the supplied screw (M3x20), that attaches the clutch to the servo, does not fit the servo.

Can someone please give me an idea of how much this thing weighs? I need to integrate it into one of my robotic arm projects.

Thanks!

Anyone know where I can get a magnetic or spring-loaded clutch like this by itself?

Definitely a claw well built for the money, cool design. What is the final verdict on servo choice? Understandably there will be need for adjustment and tweeking, but that's part of the excitement of getting something to work. Which servo has the most potential? I'm hearing some are overheating, others require drilling.. But it needs a servo so let me know people.

can anyone tell me if the claw is compatible with the "Generic Full Rotation (Micro Size) servo",model: ROB-10189 ?

what is the weight of this claw?

132g - everything except a servo ( claw, clutch, servo mount screws and nuts, clutch mount screw and bushing 94g - claw minus clutch and clutch mounting hardware 38g - clutch and clutch hardware.

Do the rubber grips on the last picture come with it?

they were included - just ordered this month.

This is the solution I found to assembly the Robotic Claw to the Pan/Tilt Bracket: http://forums.parallax.com/showthread.php/149945-My-First-but-Not-Humble-Robot-Project?p=1247433&viewfull=1#post1247433

Any word on how this works underwater? Also, does Sparkfun sell any waterproof servos that would be compatible with this claw?

Sparkfun doesn't sell a compatible waterproof servo, but search online for "waterproof park size servo" and you might find something. Check the dimensions first.

what is the weight?

Does anyone know how you could rig this up to an Actobotics channel or something...

What material is this made of? What is its weight?

This is a great claw

What material is this made of?

Claw appears to be nicely stamped aluminum. Clutch is steel.

Excellent. This claw is 237% more better than the old claw. Old claw bad - new claw good. Thanks. Ive yet to burn a servo.

what servo s compatible with this claw ?, I just purchased it and my servos do not fit.

Despite johnhenry's comments below, we just used the ROB-10333 ("Servo - Generic Metal Gear (Micro Size)") without any modification, and it fit perfectly. We first tried ROB-11887, which also fit the clutch, although the supplied screw (M3x20) that attaches the clutch to the servo was too large in diameter...

nice, thank you.

To use the ROB-10333 servo, I needed to enlarge the splined hole in the magnetic clutch with a 7/32" drill bit, which left just a little bit of spline in the hole. This gave me a snug fit of the servo shaft to the clutch.

Having same problem here - clutch's splined hole just a hair small, so it's not just you. At first I went cheap and tried other servos HK-15148, Turnigy TGY-1160A & TGY S31015 I had on hand - was able to press-fit them, but would have had to drill out the plastic output shaft to use the particular screw provided, or change to a smaller screw and fatter bushing/bearing tube. Decided to purchase the recommended servo after all, but alas... Since the clutch didn't want to fit any of these in an easy, proper manner (and it should have) - it's the clutch spline hole, not us. Other than this, I think the Claw is absolutely peachy for the price. Maybe the next will fit better, but in any case, I'm buying more of these gems.

Does this compatible with servo MG995?

This thing is horrible, do not buy. The only saving grace is that I only wasted 10 bucks on this.

Sorry to hear you were so dissatisfied with it. Is there something in particular that you didn't like? We appreciate the feedback so we can work to improve our quality.

I agree with the complaint above. Although he didn´t explain why he didn´t like it. I was very disapointed when i received the claw, when i saw it´s mostly "a toy". It´s for toy robots, like those basic small ones with bright colored plastic chassi, and foam wheels driven by constant rotation servos, that avoid obstacles with a little sonar. It´s that level of "toy" and "basic" of a claw. It´s pivot points and joints are too lose, they have some play and make the whole thing flimsy. The teeth in the gears are to wide apart, for speed, in exchange you get very little precision. Considering the small range of motin ,most of the time it´s either "opened" , "closed", or "trying to close while the clutch snaps apart". The range of motion is very limited, you can barely grab a small water bottle and barely lift it as well, since the recommended setup makes it too weak. I adapted a standard size servo to it to see if i could get a little more force, and i don´t recommend doing that, as the clutch starts to snap every now and then.

All in all, if you are starting out in robotics and like basic robots, want a claw that can grab small and light objects just to pick it up and place it down 2 inches away and then repeat in reverse, etc... this product is for you!

For anyone that thought this would save them some machining work when building a little more decent of a robot that has a little more power and can do things a little more interesting... build your own claw/gripper.

As far as i can tell, there´s still a void on the market when it comes to mid-range grippers. You can buy a decent "research class" gripper for hundreds of dollars , or an industrial one for thousands of dollars, or even a "toy" one like these for a few bucks. But if you want something in between, you´re outta luck. :(

Please ref the reply to JohnHenry above. First, thank you for a very nice claw. You should, however, ensure the clutch fits the recommended servo properly & consistently. Many of us expect things recommended by the claw mfr or sales point to actually fit nicely right off. My wife is one of those. I do as well, but don't mind a little bodge-work to set things right. Having to very tight fit on a plastic shaft, or drill / file something on a metal shaft or the clutch shouldn't happen too often. Anysomehow, My wife loves the Claw, didn't want to have to modify anything, but is now satisfied and so am I. Whatever faults the Claw has, it's price, sturdy construction and cool mag clutch really do make up for. Thanks again, and have a fab day =)

I couldn't figure how to mount this to the MkII Pan/Tilt bracket, so I designed a part for 3D printing. Files available on Thingiverse. /K

Question about assembling this claw to the pan/tilt bracket. The directions aren't clear. Should I have attached the pan/tilt bracket to the claw before I assembled the claw? It looks from the drawing that the screw and nut on the base of the claw bracket have to be removed and replaced with the M8x12 screw so that it can screw into the collar parts. Is that right? Right now, with the claw assembled, there is no clearance on the side where the clutch is to take the screw on the base of the claw bracket out and replace it with the other one. What is the role of the stand-off nuts on the base of the claw? I assume it's an additional attachment point if I didn't want to use the pan/tilt bracket. Is that right? Sorry if these questions are obvious.

I agree, there doesn't way to be an easy way to use the claw and the bracket together. I would appreciate a tutorial or hookup guide.

will this be able to lift up a softdrink can full of rice??

Does ROB-09065 servo go with this or which servo compatible with this?

We don't know what servo we can use!

Any update on pan tilt bracket?

I'm really happy I didn't order the tilt-pan bracket, having finally seen the note at the bottom of the product description.

Anyway, for $12 I'm not expecting precision machining, but this thing leaves a lot to be desired. It gets the job done, but required a fair amount of pushing and shoving to get that gear in place. The clutch was also a bit difficult to get on the medium servo, but it does fit. Just be sure you don't accidentally open the clutch, as it's only held together with magnets.

Overall it's not bad, but I'm waiting for that tilt-pan bracket!

There is an easy way to assemble the clutch but there is a trick to it.

Oh, I got it back together. Probably not the easiest way, but it works now.

Ordered this and the recommanded servo. ROB-10333 Doesn't fit.