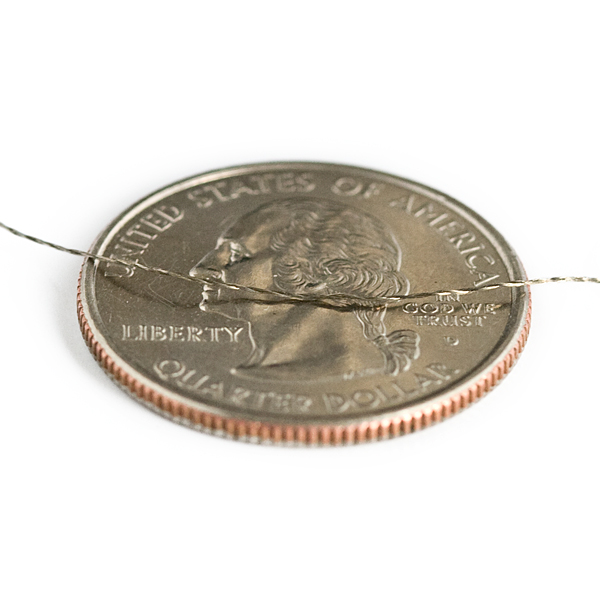

Conductive Thread - 117/17 2ply

Replacement:DEV-11791. This plated silver type thread tarnishes easy so we've replaced it with stainless steel instead, go check it out! This page is for reference only.

Conductive thread is a creative way to connect various electronics onto clothing. This thread can carry current for power and signals. While not as conductive as traces on a printed circuit board (PCB), this thread makes wearable clothing 'wearable'!

This is a plated silver type thread (as opposed to stainless steel). This is a finer thread that can be used in standard sewing machines. Resistance is about 300 Ohms per foot. Spool contains 1 oz of thread, about 150 yards.

Note: A portion of this sale is given back to Dr. Leah Buechley for continued development and education of e-textiles.

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

I ordered 1 spool of this believing that there was the stated 1200 yards on the spool. I have used a little over half of the spool and calculated that I have used less than 100 yards. NOT HAPPY!!!

For what I need, the product works fine but what will SFE do about the quantity issue?

Erm, it says that it contains 1 oz or 150 yards of thread. I'm not sure if they made a typo and changed it, but this isn't a quantity issue.

Anyone tried machine-sewing with this thread? I tried a similar 3-ply and found it would fray and jam up the stitch every so often. Wondering if 2-ply will work better.

Can you apply solder to this thread? anyone ever try?

Hi,

Thanks for the question. You can't solder to this thread. It has a nylon thread core that burns up when soldered. We are working on adding solderable thread in the near future. Keep an eye out for it within the next couple of months.

Thanks

If you want solderability, you may want to check out this method: <a href="http://rayshobby.net/blog/?p=1128">http://rayshobby.net/blog/?p=1128</a>.

I have been having some success using metal crimp beads for securing the ends of the conductive thread.

I started working with the spool I got over christmas and did have some problems with fraying especially when cutting it. I found a decent workaround was to wrap the area I planned to cut in a 1/8" wide strip of scotch tape and cut it in the middle. This left me with a shoelace type end that was also helpful for threading through holes. Hopefully this idea assists someone other than me : )

Edit: Mother-in-law (seamstress) said "just melt the ends with a lighter silly." Also works quite well.

This thread sheds all over the place?every strand has lots of tiny, near-invisible filaments that sprout out in every direction, shorting connections.

I'm trying to wire up a bunch of sensors on the back of a glove, and I'm having to insulate the stitches with bugle beads and wrap all the knots in embroidery floss. It's a lumpy, heavy mess.

Whenever I trim the stuff, I get an explosion of shreds that I then have to pick off the fabric with tweezers or a piece of tape.

It's wretched stuff.

I bought a roll of this for a wearable electronics project and found that this thread is really unreliable. It works fine for very small distances (like 10-20cm) but has many high-impedance breaks in it at random intervals.

I then tested the thread with a multimeter straight from the spool and it worked as specced for short lengths of < 30cm, but has random breaks with resistances in the million ohm region. This made the thread completely useless to me.

300 Ohms per foot is a lot of resistance for most battery operated applications. Do you have plans to decrease this figure? Can you recommend alternative materials with less resistance?

I have used this thread to make some fabric bend sensors and it works fine for what I am using it for, but I have found that it becomes less conductive over time. Is this because of oxidation of the silver in the thread? Has anyone else experienced this?

ah, i just saw the bit about the conductive coating - perhaps the coating is being rubbed off over time?

You may be right on one or both accounts. The silver can oxidize over time, decreasing its conductivity. Alternatively, if your project is being handled often or has been washed several times, the conductive coating starts to break down and slough away, again, leading to a decrease in conductivity.

Has this thread been dyed, or is it just the bare nylon?

The thread isn't dyed, but it is coated in silver, as stated in the description. The thread itself is a slightly darker, almost-brown looking color. However, the thread without the coating is non-conductive.

When you say 'coated', does that mean the actual nylon isn't visible? In other words if I were to dye this thread would it be visible, or would the silver obscure any color that the nylon might have?

You're correct. The nylon is not visible under the silver coating (but with enough patience, you could 'rub' off the coating to get to the nylon string. This would however, then remove the conductive property of the string). You could try dying the fabric, but from other attempts, I don't think the coating will pick up or allow much of the color to come through.

Before considering this, I visited the local craft store and found, in the jewelry isle, very fine copper wire (like 34 ga.) I have not yet sewn it into something, but I have tinkered with short distances on a breadboard and that worked fine. I imagine it would solder.

For 1 foot laid out on my desk I'm measuring between 300 and 600 ohms depending on how taut I pull it. I'll post more data after I thread it through some fabric.