Ultrasonic Range Finder - XL-MaxSonar-EZ4

The XL series of MaxSonars are a super high-performance version of the easy-to-use sonar range finder from Maxbotix. The XL series of this sensor features higher resolution, longer range, higher power output and better calibration when compared to the LV version.

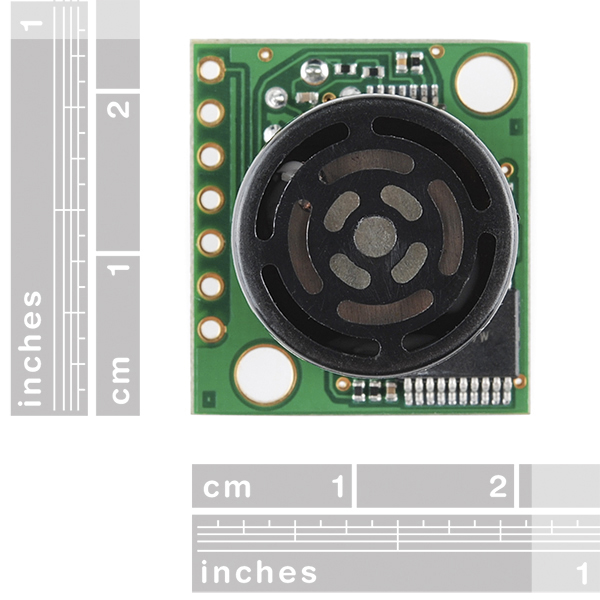

We are extremely pleased with the size, quality, and ease of use of this little range finder. The sensor provides very accurate readings from 0 to 765cm (0 to 25.1ft) with 1cm resolution. This sensor can be powered with anywhere between 3.3 and 5VDC.

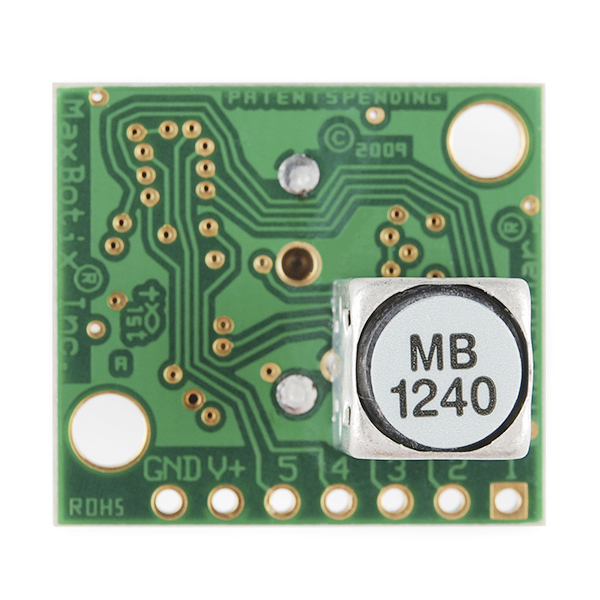

Range information can be gathered through one of three methods - analog, serial, or PWM - all of which are active at the same time. The analog output will produce a voltage proportional to the measured distance, with a sensitivity of (Vcc/1024)V/cm. The serial interface is simple and formatted to RS-232, with voltages ranging from 0 to Vcc and terminal settings of 9600-8-N-1. Finally, the PWM pin outputs a pulse-width representation of the range with a scale factor of 58us/cm.

The Maxsonar-XL series is offered in the EZ0, EZ1, EZ2, EZ3, and EZ4 versions, each with progressively narrower beam angles allowing the sensor to match the application. Please see beam width explanation below.

- 3.3V to 5V supply with very low average current draw

- High acoustic power output

- All interfaces are active simultaneously:

- RS-232 serial

- 0 to Vcc output range

- 9600 baud, 8-N-1

- Analog, (Vcc/1024) / cm

- Pulse Width

- Real-time auto calibration and noise rejection for every ranging cycle

- Calibrated beam angle

- Object detection includes zero range objects

- Readings can occur up to every 100mS, (10-Hz rate)

- Free run operation can continually measure and output range information

- Triggered operation provides the range reading as desired

- Sensor operates at 42KHz

Ultrasonic Range Finder - XL-MaxSonar-EZ4 Product Help and Resources

"RS232" Output or Inverted TTL

If the ultrasonic range finder indicates that it has an "RS232 Serial Output" and is outputting an inverting signal with the voltage level based on Vcc, you could just use an inverting circuit using a transistor to invert the signal. This is not a standard RS232 that uses +/-12V. There are a few methods of flipping this signal through hardware or software. The resources and going further will provide specific examples.

Inverting Signal w/ Hardware

Doing a quick test using a retired NPN transistor from our storefront, I was able to get it working based on the circuit using a RedBoard Programmed with Arduino. I was using an Arduino so Vcc in my circuit was 5V. Since it's basically two diodes within the transistor, you will want to use resistors to limit the current. I just used two 330Ohm resistors just like I was turning on an LED. You probably do not need to do this but the values might need to be adjusted when using it at higher speeds or if the transistor is not fully turning ON/OFF. Testing with a multimeter, it worked as expected. An input of 5V would result in 0V (logic LOW) on the output since the transistor was turning on. With an input of 0V, the transistor would not be conducting so the output would be held HIGH at 5V. Using an Arduino serial passthrough for further testing, I was able to view the ultrasonic sensor's output data without any problems.

"RS232" Output and Inverting w/ Software

Otherwise, you could be clever in writing your code to store the value and possibly apply some sort of logical NOT operation. In Arduino, there is a special feature using software serial that inverts the signal by setting a parameter to true [ "Software Serial Constructor" – https://www.arduino.cc/en/Reference/SoftwareSerialConstructor ]. There was someone in the Arduino forums that provided example code to invert the output, parse the data, and output it through the serial monitor here => [ User "Goldthing" - http://forum.arduino.cc/index.php?topic=114808.msg864009#msg864009 ].

Connecting Ultrasonic Sensor to Raspberry Pi

There is a tutorial from MaxBotix that shows you how to connect ultrasonic sensors to Raspberry Pis => [ http://www.maxbotix.com/Raspberry-Pi-with-Ultrasonic-Sensors-144/ ]. Certain ultrasonic sensors listed in the article require an inverter. If the ultrasonic range finder's output serial output is " RS232 " like the sensors listed under "Ultrasonic Sensors that Require an Inverter" , this indicates that the signal is basically an inverted output with the voltage level based on Vcc.

Therefore, you would need to follow the tutorial and use a serial inverter in order to use it with the Raspberry Pi. If you are using a Raspberry Pi a transistor, Vcc should be 3.3V since the Pi uses a 3.3V system.

Resources and Going Further

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Noob - Some basic soldering is required, but it is limited to a just a few pins, basic through-hole soldering, and couple (if any) polarized components. A basic soldering iron is all you should need.

See all skill levels

Core Skill: Programming

If a board needs code or communicates somehow, you're going to need to know how to program or interface with it. The programming skill is all about communication and code.

Skill Level: Rookie - You will need a better fundamental understand of what code is, and how it works. You will be using beginner-level software and development tools like Arduino. You will be dealing directly with code, but numerous examples and libraries are available. Sensors or shields will communicate with serial or TTL.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

Just a remark about the characteristics of the XL series.

The MaxBotics website states that if an object is closer than 20 cm it will usually register the distance as 20 cm.

For some applications this can be a problem.

Does someone know how can I connect this sensor to Raspberry pi?