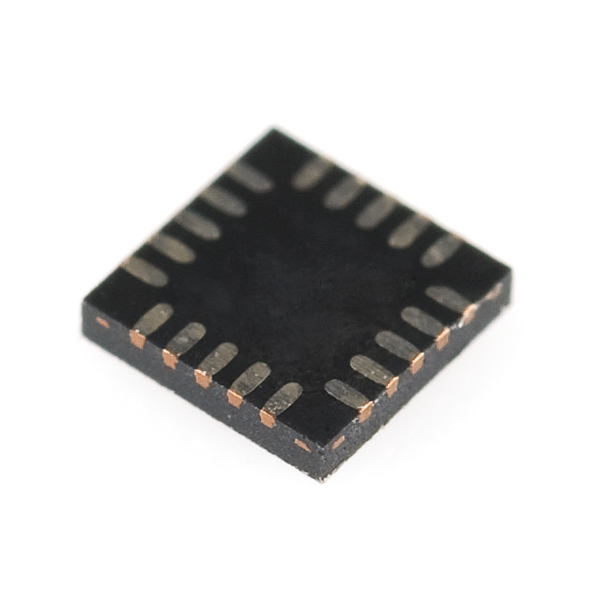

Capacitive Touch Sensor Controller - MPR121QR2

The MPR121QR2 is an I2C driven capacitive touch sensor controller, capable of managing up to twelve electrodes. The chip also has eight LED driving pins, which, when not configured to control electrodes, can be used to drive LEDs. The device also features a 13th simulated electrode that represents the simultaneous charging of all the electrodes connected together to allow for increased proximity detection in a touch panel or touch screen array.

The MPR121QR2 can operate at anywhere from 1.71 to 3.6VDC. It's an Inter-Integrated Circuit (I2C) compliant device with an additional interrupt that is triggered any time a touch or release of a button is detected. The I2C address is also configurable via the ADDR pin.

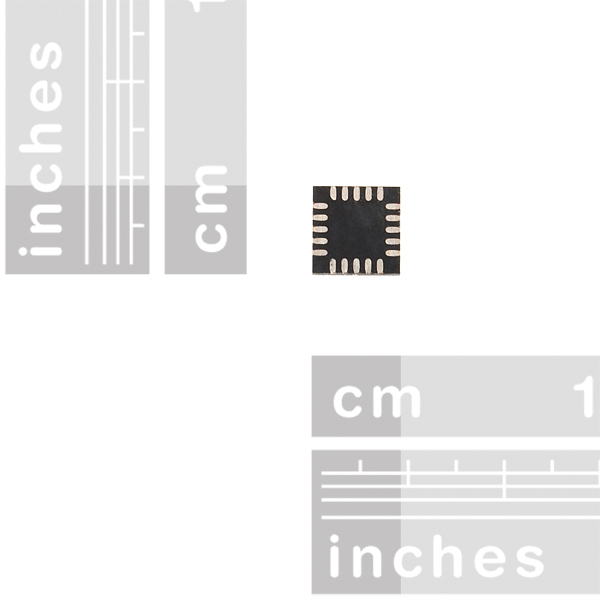

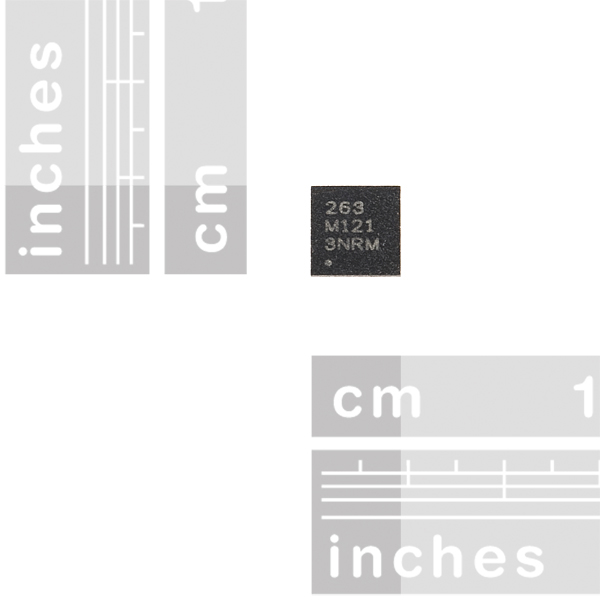

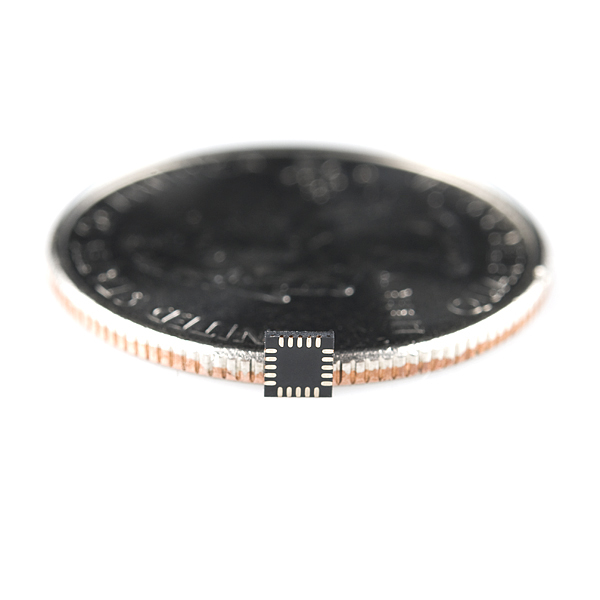

It's a tiny chip, with a 0.4mm pitch and a 3x3mm footprint. Look for a breakout board coming soon!

- 1.71 V to 3.6 V operation

- 29 μA supply current at 16 ms sample period

- 3 μA shutdown current

- 12 electrodes

- Continuous independent auto-calibration for each electrode input

- Separate touch and release trip thresholds for each electrode, providing hysteresis and electrode independence

- LED driver functionality with 8 shared LEDs

- I2C interface, with IRQ output to advise electrode status changes

- 3 mm x 3 mm x 0.65 mm 20 lead QFN package

- -40°C to +85°C operating temperature range

- Datasheet

- Example Code (ATmega328)

- Freescale's Product Page (for Application Notes, etc.)

Capacitive Touch Sensor Controller - MPR121QR2 Product Help and Resources

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Competent - You will encounter surface mount components and basic SMD soldering techniques are required.

See all skill levels

Core Skill: Programming

If a board needs code or communicates somehow, you're going to need to know how to program or interface with it. The programming skill is all about communication and code.

Skill Level: Competent - The toolchain for programming is a bit more complex and will examples may not be explicitly provided for you. You will be required to have a fundamental knowledge of programming and be required to provide your own code. You may need to modify existing libraries or code to work with your specific hardware. Sensor and hardware interfaces will be SPI or I2C.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

....must....have......break out board.......

Definitly, breakout board please :)

BOB PLZ!

The best way I know of to solder tiny things like this is to attack the pins to it and solder them all together, then take a desoldering braid and it will take off the excess solder leaving you with nicely soldered pins.

Could this be used to measure the PPM of water if you connected a PPM probe/voltage source to the water?

Does anyone know if I can use this chip as pressure sensor, like in this video http://www.youtube.com/watch?v=1UBrjMzprU8&feature=plcp ? Thanks in advance

I don't think so. If you look at 5. on page 7, it describes how the touch and release detection works and its threshold based although then you start to think, how would it know what the value is if it couldn't function as a pressure sensor.

Sorry I couldn't help, your best bet is to e-mail sparkfun tech support.

You could use this, and its on sale! https://www.sparkfun.com/products/7902

I would never be able to solder this.

Does a socket for this IC package exist? What is the best way to solder it?

awesome that the breakout board is almost done... can't wait!

I wanted to add my vote for a breakout board. Sounds like you're working on it - any approximate ETA?

One will be coming very soon. It's in the final steps right now.

hey actually, this is an opportunity to make my own break out board....do you guys have any tutorials to make a break out board?

Sure!

1.) read datasheet

2.) read eagle tutorial: http://www.sparkfun.com/commerce/tutorial_info.php?tutorials_id=109

3.) ??

4.) profit!!!!