For those of you who have been living under a rock and weren't aware, we really love robots around here. Flying robots, cute robots, ingeniously engineered robots and generally chill robots are always guaranteed to catch our eye. With this year's AVC quickly approaching (and with it being National Robotics Week), I wanted to do a shout-out to an awesome customer project with a wickedly tough-looking robot.

Meet the Hormes Robot

The Hormes robot was created by Charles and Richard Raitt, who have both participated numerous times in the FIRST robotics competition. Both brothers bring their area of expertise to the robot design process, with Richard working on the mechanical design and Charles working with the electrical systems. Beside the joy of just having a beastly, 56-pound robot, they decided that they wanted something where they "can hand the controls to someone at a Maker Faire and not worry about it getting broken. No promises about anyone's shins though..."

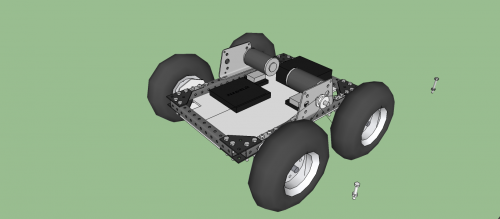

The original idea was drafted up in SketchUp before they began building.

A mid-project picture of the working drawing

With the design mostly worked out, it was material gathering time. Most of the chassis was bought from brick and mortar hardware stores. A stock 1/8" steel plate was cut and drilled on a press to create custom corner brackets. However, the 1/2-inch trade conduit (which is actually 5/8-inch ID) used in the roll frame was actually gathered as scrap practice bends from a local vocational school. This brings up a great point - where do you collect scrap materials for your projects? Let us know in the comments!

T Joint showing the frame connections

Richard then counterbored the steel axle slug inside the joints to accept an Allen bolt. A 2-inch long slug of the steel axle holds the front and back sections of the rollcage together, and barbed "tube connector nuts" hold the crossbar on and the rollcage to the frame. Richard also coped the crossbar ends to create a friction fit. This design is solid enough to even support Richard standing on it!

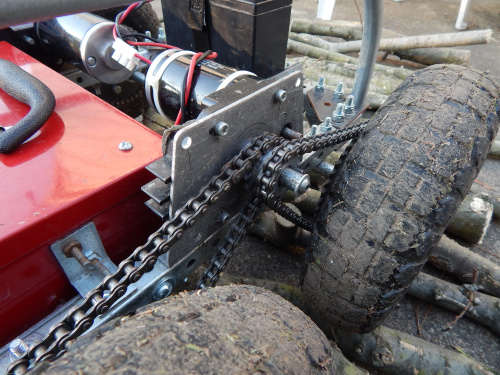

One of my favorite features of this robot is the use of the dual-sprocket on the gearbox shaft to drive the wheels. Not only is it a slick-looking design, but this design also allows a higher clearance on the robot. The interwheel space is clear of chains, allowing Hormes to tackle larger obstacles.

Snazzy dual sprocket connection for the #35 roller chain

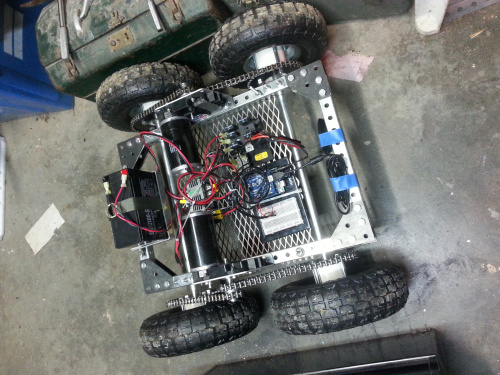

After getting the chassis together, the first integration of the electronics with the mechanical build came together beautifully, just in time for Christmas. This was the first functioning version of the robot, though it wasn't weather-proof or safe from the mud (no one wants their robot's insides looking like this after a test drive).

First iteration of the Hormes robot

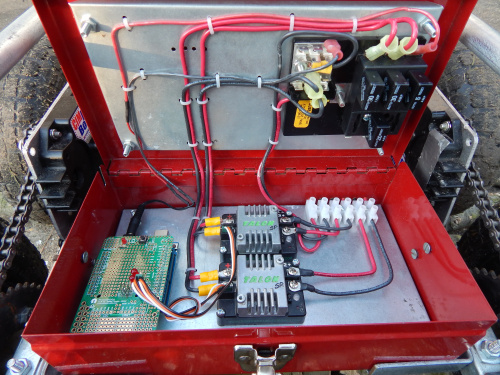

Two TALON SR motor controllers drive the two CIM brushed DC motors. The system is powered off of a sealed lead acid battery at 12V, 10Ah, running through a power distribution board. Each motor connects to its own 30A auto resetting breaker.

The brains of the Hormes are actually surprisingly simple. Charles used an Arduino Uno R3, a USB Host Shield, a PC USB Xbox360 wireless controller, and a SEEED Studio Protoshield. The proto shield has two red indicator LEDs on it. An XBox360 wireless controller functions as the driving remote. You can check out the code on the Arduino here.

Interior of Control Box

A heavy duty tool box functions as the housing for the control system, protecting the electronics from the elements and creating a solid mounting system. Not pictured above is the USB Xbox receiver, as it had broken.

While the robot itself is fantastic, I also appreciate the origin of the name. According to the brothers, "Hormes" is the Greek spirit of "putting oneself into action." Being no strangers to the project cycle, Richard says "I've started so many projects, and I swear I am going to finish this one." Perhaps my naming convention for projects has been my problem with finishing them all...

The Raitt brothers showed off Hormes at the FRC NASA/VCU Regional event in Richmond recently. They also plan to attend the Hampton Roads Mini Maker Faire in October. You can also find out more information about their robot here. We wish them the best of luck with the Hormes robot, and hope this has inspired you AVC contenders with some additional robot ideas!

I used the same Arduino/USB Host Shield/Xbox Receiver combo on a R/C Power Wheels project last year. I was shocked at the open-air range of the Xbox360 controller. Great project guys! Hope to see you in Norfolk this fall.

where do you think we got the idea?! :D highfive for jumpstarting that part of the project

This build is amazing! Awesome work guys! You've inspired me to get off my butt and start finishing projects again.

I was at the VA Regional event with my team 1086, Blue Cheese! I saw the vehicle and I believe I took a picture of it! Once I saw the talons, I knew that these people were a part of FIRST at some point.

I had the exact same thought! The CIMs and the use of lots of c-channel gave it away

haha, no C channel here. too wiggly. this is full square tube

Oh, I see now. I just saw the holes and assumed. Makes sense, we've recently had some issues with c-channel on our own robot....

HIGHFIVE BRETHEREN o/ !

An off-road AVC category would be pretty awesome.

Hi. Is the dual-sprocket custom or were you able to find it retail? If so, where?

can you tell me where do you get tour power distribution board ? do you get your gearbox from andymark ?

the PDB can be found from autoparts suppliers, but Andymark sells a usable one. and yes, the gearboxes are AndyMark CIMple boxes

I like the use of conduit for the frame :) Even simple mild steel tubing can get expensive quickly, and bonus points for avoiding welding galvanized steel... If I don't have scraps for a project or a donor vehicle/bot/etc., I've found Community Forklift in Edmonston, MD (communityforklift.org) to have some great mat'ls, especially random boxes and tins for project enclosures.

I don't think I saw a video link in the article, so: https://www.youtube.com/watch?v=Yz-KQKAffAk .

Excellent robot guys!

Fyi, semi-autonomous is a type of robot.

This is EXACTLY what I've been wanting to build, and put an ardupilot onboard for autonomous trips... My parents have 300+ acres, with walking paths all over the place, and I think it would be GREAT fun.. BUT, I've never really known where to start..

As for whether it's a "robot" or not.. how about it's a "robot platform"? Certainly I'd put a camera (and maybe an airsoft rifle or something, just for fun) onboard.. :-)

Cool, but I'm not sure I'd call this a 'robot' it's an home-built RC car that has tank style steering, in my mind a robot has to preform tasks also aka an arm, cameras, etc... Don't get me wrong this is cool and it would be fun to drive around but not a robot to me.

While I don't necessarily disagree with you, 'robot' has many different meanings to different folks. That's why for our AVC competition they are specified to be 'autonomous'.

A robot is a device that performs a task w/o human oversight. That implies it may have input from sensors, but definitely has to have a control unit to drive actuators. Thus the lowly thermostat on your wall is a robot. An RC vehicle is not a robot unless it is programmable and able to drive itself. E.G.

http://www.allonrobots.com/leonardo-da-vinci.html

To be fair the title says 'Robot platform' thus implying some additions need to be made to be classified as a 'robot'

I've seen this problem before, and it really annoys me when they use the term robot for something that isn't. A good example is the "robots" in battle-bots; they aren't in any way, ever, robots, just armored RC cars. In this case, however, I think it is completely capable of being intelligent using the arduino, they just decided for whatever reason to remotely control it.

actually, Battlebots qualify if they're anything more than just an armored wedge, because they Do a Thing - whether it's an axe, claw, or a flipper. Doing a Thing is the main differentiation between an RC and a Bot, whether or not it's autonomous

The official definition, insofar as I've heard, is a device that is capable of performing an action autonomously in one or more axis. Battlebots have no such intellegence, even those that have weapons. The weapons are invariably just mapped to another channel on the controller, leaving it up to the user to decide when to drive the mashy-spike-plate into the competitor.

Yeah, I see where you are coming from, and I agree to some extent, but also in my mind, an RC vehicle is a type of robot. Of course, there are a lot of definitions and nuances to robot-ness: something that is just a model vehicle that happens to have some level of RC, or even some autonomous ability is really a lot more of a model than a robot. But, to me this was not built to be a model of anything, and appears to be built with the intention of giving it more robotic capabilities, so it is clearly more on the robot side of the spectrum.

Hence Platform. there's a good discussion of the difference between Robot and RC in the comments here -> http://letsmakerobots.com/node/39667