We're back and we have a few new things to talk about. Let's dive right into the video for this week.

ReplaceMeOpen

ReplaceMeClose

Hopefully that gives you a little better idea of which filament to choose for your new print. If you're interested in just the filament guide portion of the video, you can check it out here.

We have a couple new filaments this week. We have 0.75kg of black NinjaFlex (also called 'midnight') and 1kg of red PLA. Both are 3mm thick and come on spools. Check the video above for help deciding which filament to choose.

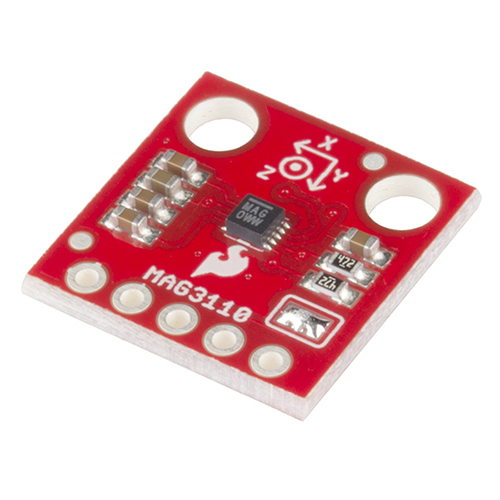

We have a new version of our triple axis magnetometer this week. The MAG3110 is an inexpensive and tiny magnetometer with an I2C interface. The new revision has a jumper so you can enable or disable the pullup resistors.

This week the ClockIt makes it into retail packaging. The kit is an easy to assembly soldering kit that magically turns into an alarm clock when you're all done. It includes everything you need but a soldering iron.

Lastly, we have a new version of our GPS Retail Kit. This kit includes the GPS shield, some headers, and the new EM-506 GPS module. This is a simple way to get everything you need to use GPS data with an Arduino.

That's everything that I have for this week. We'll be back with more new stuff next week, I promise. We have a few interesting things already showing up. See you then, thanks for reading.

You should check your temperatures for the PLA extrusions. Typically the temp for PLA is in the neighborhood of 220C, not 130C. Also, typically it is the easiest to work with...

Sorry, I misspoke. I meant to say 180 degrees. But I'll try cranking it up a little next time. I've never seen 3mm PLA extruded at 220 (I'd think it'd make a gummy mess) but it's worth a shot. Thanks for the tip!

Take into account that AFAIK there are three main grades of PLA, one of them is extruded at about 180C, one slightly above that, and one at 220C. I use the one with 220C extrusion temp and when I tried it at 200-205C extruder's stepper was skipping and extruded parts (more) easily delaminated between layers. 220C made for much nicer parts and they are surprisingly durable.

PLA's shrinkage during cooldown is smaller than ABS; that's good both for sticking to the bed and for dimensional stability - what you print is closer to what you get after cooldown.

Apparently PLA gives less smell/particles during printing than ABS (I can attest that printing PLA in closed small kitchen there's barely any smell after hours of printing) and is less harsh on more delicate lungs. ABS has somewhat unpleasant smell - kind of important if printing in closed rooms, especially in your flat.

I've been printing at 235C with PLA on my Ultimaker2 and it works just fine. On my Ultimaker Original I usually stayed around 210-220C or so. Your low printing temperature is likely what caused your test piece to de-laminate. PLA is harder than ABS so it can be slightly more brittle but with the correct printing settings it can be extremely strong. I've printed pieces that I figured would break if I sneezed in their general direction but they ended up being nigh impossible to break.

Also, PLA is generally considered easier to work with, not the other way around.

And finally, use a sharp drill bit and don't go warp speed and you'll be able to put clean holes through it no problem. For deeper holes you might want to consider adding a few drops of water to cool it down. Like most things in machining it comes down to using the correct approach. You can't machine steel the same way you machine aluminium for example.

Seconded. PLA is friendlier. That's why makerbot switched to using PLA. ABS can be quite a pain.

For drilling PLA: It's low melting point caused the bits to gum up so rather than cutting you grind a blob of molten PLA stuck to your drill against your object and make a mess. Same as if you try grinding on acrylic or a glue stick, you just coat your bit.

To compensate and keep the temperatures low enough to cut, use a hand drill. Works like a charm. Same may hold true for ABS on larger pieces. The little tab you had wasn't thick enough to heat up enough.

I mirror everyone else on PLA vs ABS: PLA is generally the easiest to work with. There's a lot a variables that can cause problems, I'd love to see what happened to attempt to troubleshoot (especially since I may be interested in picking up plastic from Sparkfun)

Too many "uh"s. Just sayin'. Do appreciate the experimentation though.