A couple weeks ago, engineer Mike Hord sent along a thank you emailed to SparkFun from Ben Hylak, a young customer we sponsored to work on his robotics project. The project, which he submitted to Google's Science Fair, is the ALAIR - an Assisted Living Autonomous Internet Robot.

ReplaceMeOpen

ReplaceMeClose

We were very impressed with Ben's project, and we wanted to know more!

Can you tell us a little bit about yourself and what you do?

I'm a soon-to-be high school senior from South Eastern, PA, who loves making and fixing. Most of what I do has some type of robotic element to it. I've made two different robots to help the elderly, and I'm also working on developing a prototype right now for a robotic lighting company - not a bad first job! One of my goals when I create a robot (and when I'm the one paying for it!) is to try to use repurposed materials, or think of things in a different way (such as the body on one of my robots, which was an old, round trash can from our barn), or repurpose them myself with machines in my shop or by making out-of-the-box adjustments. I like to think of it as "serious robots for the frugal-minded." That's why I have a tendency to keep a lot of spare parts, old printers, used circuit boards and the like around. These things used to be all over our house and my bedroom, but my parents decided to get me out of the house and into a little shed we have next to the barn that's temperature controlled and really a nice place to work.

How does ALAIR work?

ALAIR is an Assisted Living Autonomous Internet Robot. There are many situations - although certainly not all cases - where the duties of an in-home nurse or assisted living aide could be taken care of by a robot. I've seen a lot, both firsthand watching both my grandmoms live through various health crises, and I've actually been the in-home nurse myself during some shifts when they come to live with us after hospital stays. Robots can and should begin to take care of these situations. Countries like Japan are already seeing the percentage of people over 60 overtake any other age bracket; there simply aren't enough nurses to take care of simple, and basic, medical and living needs to help this population remain independent and to improve their quality of life.

ALAIR was designed with a "Base Station Model" in mind, which ultimately means that – on a grander, much more implemented scale that I have included in its programming — it would become part of a network of ALAIRs that are in people's homes (or even in hospitals or assisted living homes or nursing centers), that are monitored by humans. ALAIR includes telepresence technology that would allow the off-site human assistant/monitor to control the robot so that it can move around the person's living environment, see them and make basic decisions on whether a situation was possibly an emergency or not. I tested ALAIR with groups of elderly patients in various nursing facilities and assisted living residences, and it was inspiring to see how many people said it would relieve them to be able to contact a doctor or some type of professional/monitor, or even a family member, with just the touch of a button in the middle of the night. Many people are living alone and doing their best, but it was pretty palpable that a robot like ALAIR could give them an extra measure of confidence, improve their quality of life, and even extend the length of time they live independently. That was my main goal: to extend independence as much as possible for people and provide help to people who needed it – not just the elderly, but even younger people who might be handicapped or homebound for other reasons. ALAIR does a lot of things. I tried to incorporate a lot of functions into the design, such as oxygen monitoring, pulse, blood pressure, medicine dispensing, telepresence, temperature, fall detection and more, so that it would be adaptable to a lot of different kinds of patients in a lot of situations.

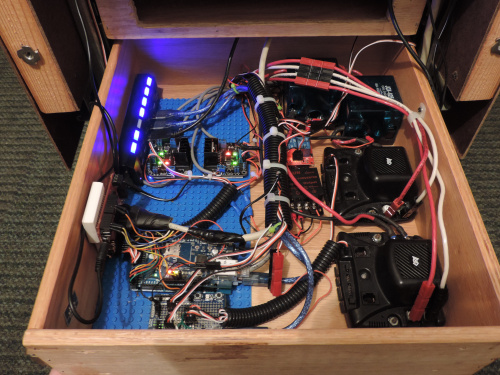

Inside the ALAIR

What was the inspiration for this project?

My grandmother, actually both my grandmoms, were my main influence. Much like my previous robot, which was a telepresence robot named MAYA (which stands for "Me And You Anywhere" and made it all the way to the White House), I saw a need and I addressed it as well as I could. When I created MAYA, telepresence technology was just becoming somewhat accessible in the "common market," that is, being used by people that were not government or big corporations, but it was horribly expensive. At that time, though, as MAYA made her rounds around the country, many people who admired it also said that it would be great if it included some type of care-taking ability. I researched it and was shocked that nothing viable really existed, so it became my next challenge.

I dug my heels into my FIRST Robotics team, where I became the lead programmer, and took all the courses I could at my high school involving electronics and programming and physics. One of the challenges I had to address with this particular care-taking robot was that part of the audience asking for it (people over 65) were not part of the robotic or computer revolution as young people, and some of them still are uncomfortable with cell phones and email. But I learned from multiple demos with my first robot that their comfort level with these devices and gadgets after just an hour or two was amazing, and it was also one of my challenges as a designer – to keep the interface simple and user-friendly, and to use BIG TYPE whenever possible!

Then, my grandmother went to the hospital (again), and she was diagnosed with tachycardia and a slew of other illnesses. When she came home, she needed a nurse. The nurse was only there for an hour or so a day, but my grandmom complained she'd sometime have to organize her whole day, and wait for hours, around that nurse's visit. The cost of a visiting nurse even with insurance is high, but it's almost impossible to pay for without it. That's the type of situation I created the robot for, and visualized ALAIR the "Robotic Nurse" becoming part of the healthcare system as durable medical equipment: something that could be ordered by a doctor and temporarily work in a person's home. Beside the nurse's important duties — many of which I programmed ALAIR to do — it was a huge task for family members to prepare and dispense my grandmom's medicines several times a day (most nurses aren't allowed to touch the medications legally). As people decline cognitively – or even experience problems with eyesight or memory – more medicines may be prescribed, and the well-documented dangers of of polypharmacy (a person mis–taking his/her medicines) increase. I designed ALAIR to solve that problem too; ALAIR features a cartridge accessed through a side panel, and it is filled on about a weekly basis with medicines in proper doses. ALAIR is programmed to know when to give what, and autonomously finds the patient on time to remind them to take their medicines.

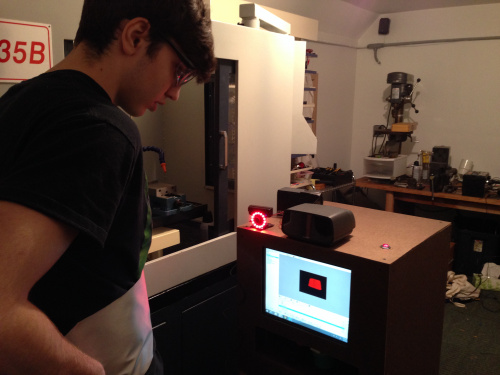

Testing the screen

How long did ALAIR take to complete, and what materials did you use? Which SparkFun parts are used?

ALAIR took just under a year of working full-time. It was a lot of time, but I learned so much from the project, and I really think it was an important thing to build. It also wouldn't have been possible without everything I was able to learn from other sources, like my classes and robotics team and SparkFun tutorials! I tried to keep the cost down by using repurposed materials. The base of the robot used to be a HoverRound wheelchair. The controller for the wheelchair was burnt out, but the motors were fine. The HoverRound was only 20 dollars from a thrift store - not bad! The body was made from Unistrut, a really sturdy and easily adjustable material you can pick up from Home Depot. If you've never heard of it, I definitely suggest looking it up. I used wooden drawers from an old cabinet on the inside to hold the laptop and electronic panel and wiring, and to allow for easy access and repair. While I'm on the subject of the electronic panel, I used mostly Anderson Power Poles, so I bought a Power Pole Distribution Board with a built-in Voltage Monitor. I also fitted the entire bottom of the drawer with a Lego baseplate (the "sheets") so all of the components, like the Arduinos, were attached to the bottom with Legos. (I just hot glued the Legos to the components.) The touchscreen was salvaged from a broken kiosk. Hopefully, I can get some more pictures up soon, but there are some good pictures on my Google Project Site.

I used so many things from SparkFun in this design! I used 3M Z Axis tape to create bumper switches. I used Arduinos (two). This sounds minute, but I used the SparkFun Third Hand to create the project - let me tell you, I'm a geek from way back, and that thing changed my life! I used the pocket oscilloscope for checking the pwm signals. I also used a Maxbotix Ultrasonic sensor - they're really fantastic sensors, the best I've ever used. I don't think I can ever fail to mention that I also learned how to solder at the SparkFun booth in 2010 at my first Maker Faire! I also met Mike Horde - who was very supportive and encouraging - at "The Feast" in the fall of 2013 in NYC. SparkFun has been an essential part of my work, my fun and my success through the years.

Inside Ben's shed workshop

Where do you hope this project will go in the future?

When I have the time, I plan to make the project an Instructables. Unfortunately, I didn't take enough video of the building process, but I think I could still do a decent job on instructing someone to make his/her own. When I build these robots, my intention is always making it available to others, because someone can use the work I've done, and make it even better. I guess I'm a maker at heart; Steve Wozniak is right up there in my list of heroes, alongside inspirational modern-day heroes like Dale Dougherty and Tim O'Reilly. I couldn't have built ALAIR without people dedicating their time to writing open source libraries for Arduino, and that's a spirit I admire and hope to emulate. I think that it's really important in this day and age that people start taking problems into their own hands, and we are going to need a lot of hands to tackle this problem. People could even make a version of ALAIR on their own, when they are younger — before they need it!

What would be your advice for someone hoping to make their own electronics project?

That's a loaded question — I don't know where to start! So much comes to my mind when I hear the word "electronics" that answering the question could go in a lot of directions.

However, once someone has a certain project or goal in mind, one of the most important things is to always use the right tool for the job. It sounds so simple, but the opportunity to break that rule arises multiple times per day, and it usually comes with undesired consequences, like breaking a part or screwing up your whole project. I think the tendency to use "wrong tools" might even be more tempting among us maker/doer types, because we're pretty used to mixing it up, inventing solutions and being inspired by our own great ideas. But I'd say in the "right tool" department, that's a bad instinct I'm learning more and more. I'm still tempted to undo every Phillips screw I see with a straight edge screwdriver almost every time, if it's easier to grab the straight screw driver. Get the right tools.

Speaking of tools, and personal work space, organization is another huge detail. I'm a big offender in that area, and since budget robotics is one of my interests, I've learned more and more how expensive disorganization can be. Organize your stuff every day to save time and money – a lot of both. The more I do it, the more I appreciate it. My grandfather is a lifelong engineer, and one of his first sermons to me after touring my shed was that. If you want to succeed longterm, organize. Make the people who work with you and for you organize as well. It's responsible and it's green. That being said, along with organization is getting a space to begin with. Designate a working space and make it yours.

Some more practical advice is trying to utilize stuff that you have around the house or you can get cheaply. You don't always have to buy parts. Broken printers and scanners are an amazing source for steppers, motors, belts.

I'm planning on giving a presentation at Maker Faire NYC next fall about creating "serious robots on a budget"- so if you're there (highly recommend!), make sure you stop by and say hello! ALAIR will be there too.

If you're a teenager looking to get into electronics, I have some further advice: Find someone to mentor you. The old saying, "Someone always knows something you don't," rings true in the engineering field. There are a lot of people who do something related to engineering as a hobby that you wouldn't even suspect. I also recommend joining a FIRST Robotics Team - it definitely requires dedication, but it's a lot of fun, and you get really amazing, hands-on experience.

For me, engineering and electronics – computers and robots – have always fascinated me. They're "my thing," and I could spend my life tinkering. In fact, I hope I will. I think finding that passion is the first place to start.

Amazing work, Ben! Thanks for using SparkFun for good and not evil, and we can't wait to see what comes next!

What will these kids be getting into next?! Seriously - as someone just entering the age group of his target audience, I hope he continues! I'm very impressed at the results here. Really multidisciplinary effort!

For a not quite high school senior yet, his project trumps about 99% of the last college year senior project/capstone efforts I've witnessed. Bravo!

This kid is going to go far... very far.

Great job, Ben! I'm very impressed with this project. I don't know where you found the time and energy to keep this going during FIRST build and competition season, but well done.

I'm expecting to see an interactive demo of this at the first meeting of MOE U, so you better keep up the good work!

Thanks Jason! It was definitely interesting to try to balance that and stay on honor roll. Can't wait for MOE to start again!

(For anyone who doesn't understand, FIRST is an international robotics competition for all ages. I do FRC which is a competition for highschoolers and I am on a team named MOE- Miracles of Engineering. We source a lot of our parts from Sparkfun, particularly the Maxbotix Ultrasonic Sensors)

Really inspired, and inspiring. And yes, I can now be certain that I squandered my own youth.

In that first picture, the blue plates, are those LEGO?

They are indeed! I'm not sure if anyone else has some the same, but I've found Legos to be a great mounting system. I just hot glued Legos to all of the components. (Arduinos etc) If I wanted to move something around or replace something quickly it only took two clicks.

I have a lot of LEGO bricks at home. So much so, a normal person could not lift them all.

I will keep the mounting system in mind. Funny thing is "System" was originally used to name the version of "The Brick" you use. (LEGO System)

It really inspire thanks for sharing http://www.testo.in/

inspiring... i'll take two!

Don't use too many spare parts. The internet audience definitely gravitates to off the shelf parts from hobbyking or sparkfun over spare parts. There's a careful balance between intrigue & sponsorship.

When you're a teenager with a limited budget, you naturally use as many recycled parts as possible. On all my projects, I've scraped together everything from Christmas money to award money to selling gift cards I've received. Of course, It doesn't make sense to use recycled parts in every situation - I could not have created ALAIR without off-the-shelf parts. There are certainly limitations to recycled parts, but that doesn't keep me (most of us?) from wanting to save money, especially on the prototyping level.

The amazing part of recycled parts is that when something is mass-produced, the parts can all obtained at a very low cost. Printers are a great example. A 5 dollar printer from a yard sale can yield a huge amount of motors, gears, shafts, etc. that could be the perfect answer to many situations. Why not use them? Another example is a drawer bearing slide. For ALAIR, I salvaged 4 perfectly great bearing slides from an old desk and converted them into linear slides. If I were to try to buy them off the shelf, they would have cost at least 200 dollars. Recycling parts can really help reduce the cost of prototyping.

Your use of recycled parts is another example of how resourceful you are! Ben - you are awesome! Trust your instincts on matters like that.