Originally I planned to write a triumphant tale of hacking skills versus mechanical failure. Then, it became a cautionary tale on Reading the Manual. Now, it's simple self-deprecating humor. Have some schadenfreude.

About two years ago, I started on the Great Adventure of Homeownership. We bought a little house up the road from SparkFun in Longmont, and started in on a Sisyphean list of home improvements.

Time passed, and it became apparent to us that our tiny little Scion xA was, in no way, equipped to manage the stuff-haulage our plans called for. After a few $100 rentals of trucks, we realized buying a cheap beater truck would probably be justifiable, and I began to scrub the Craigslist for a winner.

This was the result: Big Blue. It's a 1989 Ford F-150 with 160,000 miles on it; I got it for the princely sum of one-thousand American dollars (my spring bonus check- thanks SparkFun!). When I got it, one of the tiny sliding windows in the back was busted out and taped over; replacing that with a laser-cut piece of acrylic was my first truck hack.

Soon, however, a more serious problem reared its head: the windshield wipers stopped working. That's not a huge deal here in Colorado; it doesn't rain all that often and since I'm not using it as a daily driver most of the time, I can just kind of...avoid rainy days. Of course, the wipers are stuck about halfway through the cycle, which is annoying, but still, not that big a deal.

The wipers could, at first, be made to work by jiggling the switch a bit, but over time, even that failed me. This is, of course, the exact wrong problem to dangle in front of an electrical engineer. I mean, it's just a switch, right? Worst case, I pull it out and replace it with something from my junk box. A little research on the web found me this diagram of the inner workings not just of the switch but of the intermittent-control box and the motor, too.

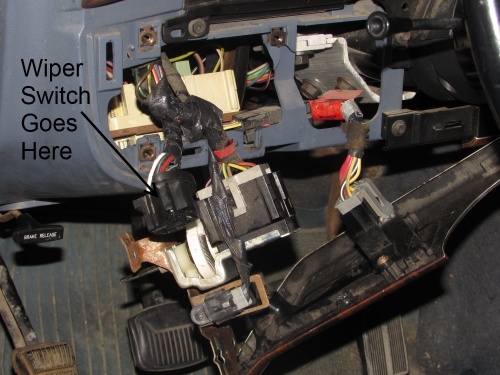

Clearly, the switch is a little more than just a switch, and there's this magic box behind it, too, which always spells trouble. So, imprudently, I decided getting the organ in question on the bench would be the best way to diagnose the problem.

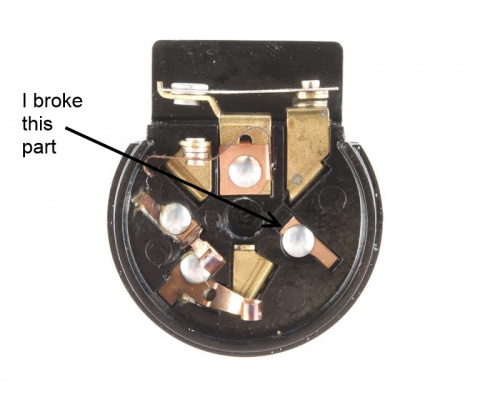

Splitting open the switch seemed like a good idea at the time, until I broke off one of the spring contacts inside the switch. Now I've committed myself to replacing the whole switch. At least I've got the old switch's connector to use and a whole bag of tricks and parts to replace the switch with.

Author's note- this post was begun about six weeks ago; this is as far as I got. Originally, this was to be the point where I described the hack I used to fix the problem.

This is the nifty little kludge I put together. It replaces the original super-complex switch with an on-off button, a high-low button, and a washer pump button. Confident in my skills, I plugged it into the system, fired up the truck and pressed the button.

Nothing happened.

Well, not nothing, just not the something I had hoped for. I poked and prodded a bit, took some voltage measurements to make sure the switches that were supposed to be closed were closed, the ones that were supposed to be open were open, and that the power supply was supplying, and got a fairly unpleasant burn for my trouble. I replaced the switch with my meter in ammeter mode and discovered that 9A(!) was flowing, despite the lack of any activity in the motor!

(All this testing was going on in the SparkFun parking lot; I walked away from the truck with the door open and killed the battery, which led to an [abortive] attempt to jump the truck with some LiPo batteries.)

So now, six weeks later, my wipers are still broken, my wiper switch is shattered, and I'm pretty sure it's a faulty motor, anyway, since all efforts to fix it at the switch side have failed. In short, I probably should have just pulled out the Chilton's manual and followed the directions; that's certainly what I'll do in the future.

It must be a Longmont thing...I have an 85' 4Runner with wiper problems. Luckily I'm walking distance to The Pumphouse and I have an umbrella.

Fords can fail in strange ways. My old Tbird started to run rough, then eventually very jerkally. It also 'smoked'. Turned out that the downshift connection from the automatic transmission to the carb was via a vacuum line activated by a diaphragm in the tranny. The change in vacuum pressure pulled on the membrane which activated the downshift. Eventually, the membrane developed a hole allowing the carb to suck out the transmission fluid (!) and the engine burned it(!!). So my transmission was slipping due to lack of fluid. Great thinking Ford!

Not a downshift mechanism. That's the vacuum modulator, which modifies the shift points according to engine load (eg. manifold vacuum). The downshift is the rod extending from the back of the carb off the throttle linkage down to the transmission. It's a relatively common failure point in GM's, Fords, Dodge's, basically anything with an automatic transmission of that era that used a vacuum operated diaphragm to modify shift points.

I guess you're correct, but in my mind it is the gizmo that causes the transmission to downshift when I mash the pedal to the floor to pass.

If that diaphragm was ruptured, you would get no fluid transfer from the transmission to the intake manifold, because when the pedal is mashed, there is no appreciable intake manifold vacuum, therefore no flow. The flow (smoke, etc) will happen when you let off the pedal and generate maximum manifold vacuum, eg. high rpm's, low engine load, deceleration. The vacuum modulator decreases transmission fluid line pressure to the shift valves in response to manifold vacuum. More throttle = Less manifold vacuum = higher engine load = less transmission fluid line pressure = need to have higher rpm's in the transmission, more accurately at the governor, to generate the required line pressure to activate the shift valve for the next gear. And it's essentially out of the picture once you get past about 1/2 throttle in most situations. When you "mash the pedal to the floor", you are activating the 'detent lever' which is another valve in the transmission which basically dumps all shifting line pressure until the governor (which is driven by rpm) is able to overcome that and allow an upshift. So, in short, if you've got a blown vacuum modulator diaphragm, the only way to keep it from smoking, is to run the engine wide open all the time (eg. no manifold vacuum) or not run it at all (eg. again, no manifold vacuum). Need to split these gizmo's into two categories... vacuum modulator = adjusting normal up and down shifts at normal throttle positions (and causes smoke when it rips) detent valve = the downshift when you mash or the upshift when you un-mash.

I have exactly the same '89 F150 truck (actually with the stretch cab) with the same problem!

My brother in law "gave" it to my wife (we had to pay to get it to pass safety checks in Ontario) and I drove it up from New Brunswick. Half way home it rained and the wipers quit... had to drive an hour or so with no wipers (traffic was very light). When we got back the have worked ever since.

I did some research and apparently the solder joins in the "black box" have a tendency to fail, probably due to the vibration from releasing the parking break with a "snap", as it is mounted just above it. I have not actually tried fixing it as they have not failed again and we only use it to tow our boat locally on sunny days.

Here is the original info I found:

"There's a relay in there, and I found the solder joints for the relay on the little circuit board in there had broken. A little solder fixed it right up."

http://www.f150online.com/forums/electrical-systems/131673-f150-windshield-wiper-governor-location.html

Good luck!

Oh the irony! I had one of the first vehicles with LED tattle-tale lights, that report burned out tail lights. When I then had a problem as most of the vehicles tail lights stopped working it was caused by a failed solder joint INSIDE that LED module.

Wish I could take credit for finding and fixing it.... The dealership repair shop ($$$) donated the then 'dead' LED module to me for a postmortem. The failed solder joint was hard to find but right near a power resistor (the in-line current shunt to detect if a brake light bulb was open circuit)

I've touched up most, if not all, of the joints in the black box.

Also, I think the black box is bypassed in HIGH mode, and I've tried jumping the two wires that should turn the motor on. No joy.

In retrospect, I attacked this in a much less methodical manner than I'd have with, say, code or a recalcitrant circuit. I don't know why.

Yeah, but look how rewarding the learning experience has been - and will continue to be for the foreseeable future!

All kidding aside, you took the right path. Keep having fun!

Edit: it looks like the store in the photo right behind the truck has a good supply of 'fix-it' ointment.

Liquor on a Tuesday Morning. Sounds about right.

I'll tell you what I tell everyone about fixing cars, washing machines, furnaces, etc.

Most products, no matter what they are, have relatively few failures that are completely random. Much of the time a particular product will have the same failures over its lifetime and people will post their problems online.

When the windshield wipers didn't work, the first thing I would do is go to google, enter year, make, model, and failed component. 80-90% of the time, someone else has already encountered the problem and fixed it. When there was a high pitched squeal coming from under the hood of my Saturn, I went online and found out that the water pump nearly always dies after 120,000 miles. Sure enough when I replaced it, I not only found that it was in the process of failing, but the bearings were so loose they couldn't hold the pully straight.

Go forth and google. It will save you a lot of messing around reinventing a solution. :-)

Years ago, I had a 67 Mustang in which the wiper linkage became disconnected. I positioned my body upside down in the foot-well and reaching up under the dash to feel for the linkage with one hand I turned on the wiper switch with the other hand. Big mistake! The motor cycled and pinned my hand. Turning off the switch (which I could barely reach from my position) did not help as the linkage could not finish it's cycle because some idiot had put a hand in the way! I managed to extract my hand with a lot of torn skin on the palm and backside. Lesson learned with negative re-enforcement.

"I walked away from the truck with the door open and killed the battery, which led to an [abortive] attempt to jump the truck with some LiPo batteries."

I'm sad I wasn't there to see that.

Thank you for the great laugh. Attempting to jump start a truck with LiPo batteries. I expect this was either a large bank of batteries, or a fail. Either way, I would love to see video of this.

I understand the chest thumping "I am an engineer, I can fix it". I have fallen into that trap, too often, as my wife would tell you. <pitiful laugh> It is good to know that I am not the only one out there who has fallen into this trap.

It's not that inconceivable. A starter motor draws 250ish amps at 12V for a few seconds, and RC Lipo packs (without protection circuits) have breathtakingly high discharge rates. If you had ten of these charged up and sitting around (5P x 2S), I'll bet you could do it.

I had no illusions that the batteries could provide enough surge current to start the motor; the battery wasn't all dead, just mostly dead. I figured a couple of minutes of dumping current in from the LiPo stack would maybe be enough to push me up into starting range.

Turns out, just letting the truck sit for a couple of hours did the trick. Later on, I experimented with roll-starting it, in reverse, from a similar spot, and that worked, too.

I didn't want to take the risk, though- I didn't want to be the jerk with his truck covering the drive path through the lot.

Also note that, at any time, I could've sent out an APB for a jump and solved it immediately, but that's not how we roll at SparkFun. Never ask for help when a hack of questionable function is available.

Ford wiper motors are also known for seizing from corrosion. You can drill an access hole in it, and blast in a lot of wd-40, pblaster, or whatever your favorite spray stuff is...

The switch sounds like it is toast - easier to get a new one. The 9A it was drawing is consistent with a stalled motor.

Automotive protip: Always make sure power is getting to the "end device" first and then trace it towards the power source. There are lots of low current and/or voltage controls even in older cars.

The first thing, after checking the fuse, is to wipe the windshield with Rain-X so that any rain or snow slides off and you don't need the wipers. Second, spray any switches with De-Oxit or other contact cleaner without disassembling the switch, and, finally, spray the motor shafts and the wiper linkage points with Tri-Flow or something similar to eliminate any binding or other friction related issues. Do these steps before any disassembly. Be guided by the Occam's Razor principle. Don't create a big problem to fix a simple problem.

Rainx isn't the best anymore, it just seems that it was one of the first.. there are a couple products that best it these days.

http://youtu.be/K-qhq_AigpM

Just a note about jump starting a car with LiPos, since I've had the idea, and my dad is a seasoned mechanic: Car battery's have a thing called cold cranking amps, which basically means the amount of amps they can supply in short bursts. This is basically the amount of amps needed for the starter to turn the engine over and start the car. My dad's truck, Chevy Silverado, needs about 75 cold cranking amps to turn over. So unless you've got a LiPo that'll supply something like that in one short burst, then that's not going to happen.

I think you are off by an order of magnitude. Most cars require 200-400 "cold cranking amps" and trucks with big engines require significantly more. Yes, starter motors draw a couple of kilowatts of power. However a car battery could be charged slowly by a lithium battery and then the car could be started once the battery was fully charged.

Experience is the ability to recognize that you've made this same mistake before.

You did check the fuse, right?

Enjoyed your post! "Wrenching on your ride" is an Engineer's right of passage. Younger EEs don't have the hands on opportunity in our ever more complex world. Key discovery? Automotive switches were often designed to go "about 100k miles"... and then fall apart. Key learning? Isolate the motor wire(s) first. Jumper to the battery (with a headlight bulb or a blade fuse inline) and see if it moves the wipers.

In the "Wiper Motor Assembly" that thing that shows "run / park" connected to the motor itself is supposed to bypass the switch and the timer assembly when the wipers aren't down (parked).. ie: you can hear the relay click on, then off (before the wiper makes a full cycle) or you can turn the switch off in the middle of a cycle, and the wipers will continue until they get to their parked position. Because your wipers are stopping in that upright position, I would either say that the motor is installed wrong so it THINKS that's the "parked" position (maybe the motor can be installed 180 degrees out of phase??) or there's something wrong in the motor housing, and you're attacking the wrong part of the circuit entirely..

I'll definitely be interested to hear the eventual solution..

Technically it may be a failure, but you learn so much in the process...may be good topic for the Hack-A-Day Fail of the week (may not be very helpful cuz most of those bowels are eternally stuck in the TIGHT position )...

For car hacks i generally just try to replace the part: http://www.partsgeek.com/8zsmjbt-ford-f150-wiper-switch.html?utm_source=pricegrabber&utm_medium=pf&utm_content=mc&utm_campaign=PartsGeek+Pricegrabber&fp=pp&utm_term=Ford+Wiper+Switch

Maybe take a look at the local hackerspace TinkerMill on Delaware in Longmont. Could post a meetup and have a brainstorming session on how to fix it...?

As long as the truck is still operable, I think this was a success! Just loved this post. Reblogged it here: http://illinois.edu/blog/view/6010

The wiper motor failed in my buddy's old pickup many years ago; and when he found it intractably difficult to access, much less replace, he attached a piece of heavy twine to the wiper arms, and ran it in a loop: into one of the vent windows, through the cab, out the other vent window, and to the wiper arms. The passenger grabbed the twine, moved it rapidly back and forth, and the wipers worked. Well, anyway in a typical light Seattle drizzle, they worked. But out on the freeway, 55+ mph and a gushing downpour... It seemed funny later.

Total success! All your pain has been added to the open source world and now we are benefit. You get to reduce your pain by sharing it and we get to learn from it without spending the time or money.

You have my sympathy. Having grown up with a father who is an ASE-certified master technician, I don't know the first thing about fixing cars.. I simply called the old man when car trouble arose. He's retired now, though, and not-so-able-bodied.. so I've been trying to learn a few things from him so I can handle the basics (and not get ripped off when I have to take it somewhere for service).