In my last blog post, I unveiled the design for the arcade cabinet that I am going to build this month. During the brainstorming for the cabinet someone tossed out how cool it would be if I could cast my own skull joystick toppers. I think it was intended as a joke, but I took it as a challenge. The following week I planned how I was going to cast the skull over the weekend. A month later I finally succeeded in creating a skull...here's how it went.

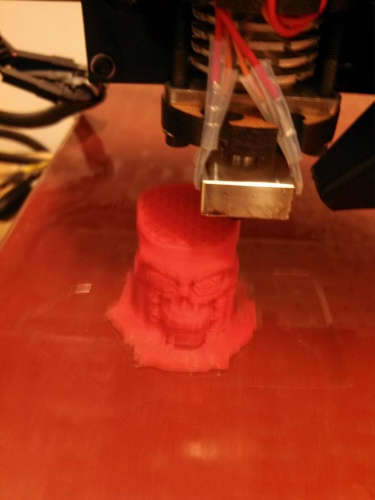

Initially I was going to try to carve my own skull from wax or foam. After some experimentation I quickly realized that I didn't really have the artistic chops to pull that off. I found a few people online doing lost-pla castings, and that method seemed fine, but I am not a huge fan of babysitting a 3D printer and I figured there was a good chance I was going to screw this up at least once.

I remembered seeing a silicone mold making kit at my local hobbystore and I thought that if I could create the silicone mold, I would be able to make wax copies easily and quickly for the metal molds. I decided on a ABS print so that I could try giving it an acetone bath.

Sorry for the poor photos, documentation is never my first priority.

The acetone bath was easy but required a little bit of experimentation. I tried putting the acetone into a spray bottle and selectively spraying the model but that didn't seem to do much. In the end I think I just gave it a few quick dunks in a small cup.

Creating the positive for the mold was a bit frustrating for someone who had no idea what they were doing. The above picture was from my first attempt. It didn't hold well as you will see in the video. In the end it took me 3 tries to successfully create the silicone mold.

The positive kept failing because the skull would lift off the clay supports and the mold would be ruined. In hindsight, the final positive design is actually very poor. As soon as wax is poured into the sprue, the air vents will get clogged. Luckily, due to the durability of the mold, I was able to just throw it in the microwave full of wax and it would evenly fill out the cavities.

While pouring the silicone I did what is called a high pour. It causes the silicone to stretch out and release any air bubbles that were trapped inside during mixing. You also need to make sure to pour the silicone into the lowest point of the mold and let it fill in the cavities of your positive.

Once I had the wax copies I started on creating a forge to melt the aluminum. I followed a really fantastic tutorial by The King of Random on YouTubd.

The hardest part about the forge was figuring out the airflow. I tried an air compressor but it seemed like it was too much air and usually made a big mess. The shopvac worked but was quite loud. I found that the blower from a $3 hair dryer at goodwill worked great.

For this mold I went with a 50/50 plaster mix, just like I used for the oven's refractory. I simply poured some in a cup, then dipped the wax model into the plaster, poured around it and pressed down on the top (for some reason that seemed like a good idea at the time). After letting it harden I just chipped away a few pieces of the top of the plaster to expose some wax and evacuated it the same way I did the sand mold.

There was too little material around the wax model, and the pressure from the wax expanding during the evacuation made it crack, but that did not seem to hurt the resulting cast too much. I think most of the deformation here was caused by me pressing down on top of the mold as it solidified. Honestly, I think I'm pretty lucky this even remotely worked with all the mistakes made.

Before creating this mold I decided to do a little reading. I learned about how a big tapered sprue is important to build up pressure and push the molten metal into the mold. And I learned how to use gates and runners to capture any impurities that might fall into the mold during the pour. Also, a riser is important for two things: 1) to help prevent cavities due to shrinkage, and 2) to be able to tell when the mold is full.

Another great thing I did for this pour was to cover the top of the mold with aluminum foil. Once you go to pour the foil will liquefy when the aluminum comes into contact with it. This keeps the sand out while you build a small "volcano" of sand on top to generate even more pressure.

Unfortunately, I shocked the molten aluminum by adding a bit too much to the forge right before I went to pour. I didn't have enough to fill the mold and ended up with this weird squished alien head thing. This is probably my favorite of the castings.

This mold had a bigger sprue and I made the mold significantly larger than any of the previous ones. I used a cheap unscented dinner candle to drip wax to use as a glue.

After filling the mold with plaster I set it on a diy vibrating table. After evacuating the wax I left the mold in the oven and turned it up to ~450F. I did this to try to keep the aluminum molten for a longer amount of time inside the mold. I sure wish I had a kiln! ;)

I made a mistake when pouring; I decided I wanted to puncture the foil above the riser so that I could more easily see if the mold was full, and a big chunk of sand fell right into the unprotected area. You can see that sand in the teeth area of my final casting.

Sorry for the vertical video!

Those skulls looks great. I also recently followed the King of Random's video about making that furnace. Before that I was using charcoal and that just gets old fast. I started a YouTube channel where I take the aluminum that I've melted down and pout it on random things. Thought that you might like it. https://www.youtube.com/watch?v=CyX5zCvm8Is

Thanks, I'm going to attempt something like this soon so the post is very helpful. I have had great success in acetone smoothing usng a crock pot. The fumes are very dangerous so an abundance of caution is a good thing. I give the details halfway through this post on some cold-cast stone from a 3D printed model: casting the bean. It was my first time with silicone mold making and it went very well. That page details the whole process, including a long video on the casting and finishing process. On to hot casting!

This is awesome! I need to try this!

me too. I saw the mini metal foundry video awhile back and now I really want to cast something... anything.

The wax casting wasn't necessary. You could have done the initial print in PLA and then encased that in the plaster investment. The PLA could then be burned out in the same way that the wax was, although a bit higher temperature would have been required (could be done in the same furnace that you melted the aluminum in).

I've had success in the past smoothing with acetone vapor. Heat it, but not in a sealed container (unless it's pressure rated), and not near a source of flame. Finding a ventilated area is easy enough. Deposits an even layer of acetone and you can stop when you get the desired result.