We were surprised recently when we launched two versions of a popular board - one with headers and one without - and the one with headers outsold the other 3 to 1.

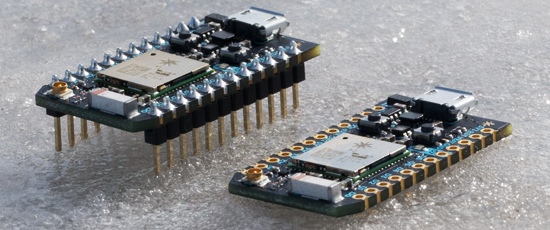

These two Photon boards were launched a few weeks ago. The Photon with headers outsold Photon without headers 513 to 177.

The boards sell for the same price, but our own engineers design PCBs and most often prefer boards without connectors populated, as they need to solder in connectors or wires in any orientation they need. A number of SparkFun production techs are expert solderers and can solder as well as most of us walk and never have to endure the pain of having to remove pins and solder from a board.

There are also a multitude of 0.1” spaced headers out there, and that often factors into our decision not to include headers. By leaving the vias open, we give the customer the freedom to use the headers they feel will best work for them.

A board without headers is also ultra-thin and lightweight, and can more seamlessly fit into a completed project. One of our all-time top selling boards is small and has a flexible form factor – the Arduino Pro Mini. A customer commented, “No headers makes it easier to put an Arduino in a permanent project.” Soldering is often thought of as “a skill that everyone should have.” Here is some good information on how to solder pin headers to an Arduino Pro Mini.

For these reasons, we have come to believe that a majority of our maker audience prefers to hand solder pins according to their own specifications.

However, we do understand that beginners can get into a mess as they learn how to solder, and can even fry a few boards along the way. We occasionally also hear feedback such as this product comment, “I didn’t realize I had to solder the pins on myself,” and this one from a reddit thread, “Soldering those header pins is kind of a &^%$#*#%&.” Because of this, SparkFun does make some boards with headers already soldered on. After all, they have to be soldered in straight or they won’t line up properly with the headers on the breadboard and connections will be lost. Buying a board with headers can help make your system less flaky.

Another reason we make some boards with headers is to make prototyping (and breadboarding) easier. Boards with headers are good for those who want to plug in shields without any soldering. The headers often plug directly into standard breadboards and perfboards, and can also be mounted on a PCB.

How about you? Would you pay a little more for a board with the headers already soldered into place, or do you prefer boards to be stripped down to the essentials for embedded devices? Have your preferences changed as applications shift from projects to prototyping?

Why not both? /s Solder a header to every other pin.

Personally I prefer how Adafruit does it. Include the headers, but don't solder them.

Yes, just include the damn headers, not all of us have bins of headers lying around.

Make it a zero (or low) cost option to throw in headers of either orientation and just throw in the nearest multiple of 20 if that causes too many supply chain issues.

As to pre-soldered headers, I think they are bought under the reasonable assumption that SFE is really good at soldering them straight. I can solder fine, but I hate even slightly crooked albeit functional headers.

As others have said, also having the option to just add soldered headers of various shape/length/orientation would be also worth a few bucks to me.

The reason your header-ed board outsold the other is probably because most people getting into this for the first time (and probably don't hang out and comment much) wanted a lower bar of entry. All your experienced customers (and the ones that hang out and comment) went the headerless route because they have the capacity (time, equipment and experience) to do the soldering needed. Totally my guess and opinion, though.

I can only speak for myself, but as much as I love tinkering and making projects, I usually only have small windows of time here and there to work on it. I have a number of boards I was really excited to play with when I got them...sitting there waiting to get their headers soldered on. While a board with headers already on can just be dropped into a breadboard and off I go. I finally came to the conclusion that if I wait for time to pretty up my projects with everything soldered up nice and neat, I'll never finish a project. Instead, I can just hide an ugly mess of jumper wires and a breadboard in a box and I get to actually use the projects in a practical way. I also don't have a workbench - when I do need to solder I'm plugging it into the closest outlet and throwing a piece of cardboard under there to solder it up real quick, because I've got 15 minutes - dining room table, bathroom counter, on the floor... I'm sure a lot of tinkerers have a nice workbench setup and the idea of soldering some headers on is no big deal. But for me, 4 times out of 5 I'll buy the board with headers if I have the choice so I can be up and running out of the box. As others have said, though, having both options (soldered and unsoldered) is ideal.

Yup. And even though soldering headers on usually isn't that hard, it's still tedious, something to be done only if the board didn't come with them (or came with the wrong shape of headers, whether that's male/female or straight/right-angle or whatever.) For prototyping, plugging a wire into a female header is trivial, or plugging a male header into a breadboard (though that's becoming much less convenient as products go to 2xN headers, but you can still plug a cable onto them.)

Having a choice with headers would be worth a dollar or three. If I only get one choice, I'll take it without headers so I can embed it in a project. Unsoldered headers in the bag would be a good compromise, as mentioned, anyone playing this game needs to learn to solder, and after you get onto it a bit, a few seconds will solder in headers.

Jim

My simple question is why only male headers? If you really want to give the customers choice I would say to include headers, leave them unsoldered and allow for the choice between male and female headers.

It's nice to sometimes just grab a part and throw it into a breadboard, but If I am designing a project that will be used for any length of time at all I want permanent connections. Especially if it will be subjected to less than optimal conditions.

Edit: after reading other comments and thinking more on it, I now would have to say leave unsoldered and let the customer choose from the widest possible variety of headers. Male, female, stackable, right angle, etc...

Unsoldered headers in the bag, please. In fact, I'd love to see this for every through-hole connector. Raspberry Pi without that stupid useless yellow RCA connector would be lovely (I know, not Sparkfun's call, but mentioned as a ferinstance)..

Another reason for unsoldered headers is that sometimes you want the pins on top, sometimes on the bottom, depending on where the cables come in.

How about throwing in the appropriate headers in with the (un-header-ed) product?

If you want 'em, just solder 'em on! As Jim #465537 says, "anyone playing this game needs to learn to solder." Not having to stock two versions has got to save enough money to provide the headers for anyone who wants to add them. (Apparently cost is not a big issue since the Photon was the same price with/without headers.)

In SF designed boards, do you use Pete's clever technique to get the headers straight? If you do this, I'm much more comfortable with soldering them myself. Otherwise, getting them perfectly seated and straight is a pain without a special jig.

Hi saccade,

We do still use the locking footprints for some of our products that get headers populated in-house, like the ludus proto shield. Although it does make alignment easier, we prefer the aesthetics of straight headers (to keep a super clean looking layout), so most of our designs use the straight header footprints.

Locking footprints are most useful when populating the parts in panel form before going into our selective soldering machine. It helps hold the parts in place without needing a huge jig to mate with the entire panel. Sometimes a panel may have over 100 parts go into SS, and so making a mating jig is quite the design project. For single board soldering, we recommend using a breadboard (as MicroLAN suggested).

That being said, my team and I (in QC) use a lot of locking footprints on test jigs (to keep things perfectly straight). Although I'm always stoked on a nice looking test jig, we are not as concerned about the look cause they don't hit storefront. We also get to use auto-router too - wahoo!

Thanks for linking to my old tutorial. Wow, 2007, that was a fun trip down memory lane. We've come a long way :)

Another technique that I use is to stick the headers in a breadboard, set the target board on top of the headers, and solder. This works best with boards that have more than one set of headers (otherwise, it won't sit flat and you'll need to shim it on one side to make the board level).

Here is a question for everyone requesting headers included with the board but not soldered on. How does this differ from you ordering the product and the headers you want separately? What advantage do you see other than only having to click 'Add to Cart' once instead of twice?

In short, it's a value add service to me. In an increasingly growing market of competition setting yourself above or in line with your competitors is key. If the headers come with the product its less hassle and less work to track them down. It also feels like an incomplete dev kit to me if I have to purchase parts to make it work separately. I understand soldering them on is a secondary process in manufacturing and I DFM(design for manufacturing) for my day job every day so I see the appeal to leave them off as a company. I really think throwing them in the bag is a huge value add and in the quantities bought are usually dirt cheap. If I don't have to go looking for header pins in my lab or spend an extra buck or 2 on them I feel that is a huge value add and time savings for me. A perfect example of this is an Arduino shield. I rarely double stack shields and if I buy a shield I'm going to be attaching it to an Arduino. Why would I want to find header pins just to use it.

Perhaps it is because it is harder to find the right headers on our site than we would like.

It depends on which headers. If you are talking about standard male headers, then yes, you can buy the 40 pin sets of headers and cut them down to size.

However, for female headers, particularly stacking headers, it can be an interesting exercise to find the right size headers. Yes you can cut down larger headers, but then you need to use a dremel or sander to smooth down the edge, and you can't group multiple headers together without sanding. I've been searching for 14 pin stacking headers (for Teensy) for some time.

It's not that hard to find the headers. The suggested items usually have the right ones. I worry more about driving the picker-people over the edge into a darkness from which they cannot escape.

I'm sure our pickers appreciate that. I think it is actually more likely to drive them over the edge having numerous versions of the same board (no headers, male headers, female headers, right angle headers... the list never ends) not to mention our packagers who put the boards in the bags and now have to add headers.

It may just come down to the feeling of buying a complete product.

SFE is in the business of selling shortcuts, so all these little breakout boards should just sort of come with at least some cheap male headers in the bag, by default, as a no-brainer for us 1:00 AM engineers who probably forgot them the last time we allowed ourselves an order.

It's not that we are entitled to header pins, it just makes the product feel more satisfying, like those nice red boxes, which I was disappointed to see missing from my last order (no biggie). It doesn't take a lot to make something feel more premium, even if it's all in our little consumerist heads.

If I forget to buy the header then I have to come back and pay an additional shipping charge for a trivial component. As miked13 says it's a nice value-add for your breakouts. Adafruit includes headers and I was very pleased with that small bit of consideration when I first encountered it.

Honestly, it just caters to my inherent "laziness." As I design projects that can be quite complex and easily use hundreds of components, it's not really an issue of selecting the right part (I have to do that a lot, anyways). Most headers used by these breakout boards are fairly standard, anyways. Just laziness....

Headers are great for those of us that still wire-wrap.

I myself would almost always prefer headers in the bag with the board (Pololu does this a lot for both straight and right-angle). Sure I have my own stash of headers, but if they come with the product I don't have to go and check my stock or make sure the spacing is correct before purchasing. Then again, I wouldn't complain or have any issues if you sent me a pro mini with all the parts unsoldered and in the bag, so maybe I am not the best one to judge.

I can see pre-soldered being a good option in two cases:

Beginner boards, especially any beginner SBC, as a lot of software focused individuals get these before they really get into electronics enough to invest in a soldering setup.

Expensive boards. I get a bit tense when soldering on something over $100, so I would appreciate the option to have that done for me from time to time. That said, it would also be important to keep the original unsoldered version, as if I was a little worried about soldering the pins on, I would be petrified about removing them.

Thanks, those are good points. We actually recently change the Pi Wedge from a soldering kit to a presoldered assembly for that reason. We are also starting to get more kits with sensors and such in them and are finding it necessary to solder headers onto parts for that reason. I'll look into the expensive boards. We don't currently make many $100 boards but it is worth a recommendation.

Offering the product without the headers installed, but headers included is my preference as it saves the hassle of sourcing headers, and potentially unsoldering them if their product would require odd headers or no headers (like in wearable situations). Soldering .1" headers is a pretty easy task.

For those who lack the soldering equipment but want to use the product on a breadboard, offering it with the header pre-installed is also nice.

I have a few bins of pin & socket, gold-plated headers on-hand for just this situation. I buy 36-pin or 50-pin "breakaway" pin headers. Socket headers, when cutting, you have to sacrifice a pin, and file the end flat. For good reliability, never use tin or solder-plated! Always use gold-plated; the cost differential is worth the time you'll save troubleshooting a flakey pin! I always buy header-less boards, if possible, because they're often a bit cheaper, and soldering headers only takes a few minutes. Often, I'll buy two boards, and solder pins to 1, and solder wires to the to the other board, if it's going into a project. The first board is for proof-of-concept demo & firmware development. The 2nd board goes into the alpha-prototype.

I've done tons of projects with various boards, and I'm very comfortable with soldering on headers. I've had issues with OEM headers & sockets (Ardunio style) not lasting as long as I'd like and having intermittent open circuits. This is a pain to track down and debug. So now I buy everything without headers if at all possible, and I install high quality gold plated headers myself, and use gold plated jumper wires to connect everything. Or I use longer headers so I can solder a shield and Arduino board together and not worry about connector life at all. What I would really love is a version of the SF Redboard with PTH holes instead of the sockets! But the Pro Micro or Pro Mini isn't a bad alternative.

This blog post is a little old, but you may want to look into swiss pin headers as well. They are supposed to have more reliable contacts than the standard headers. Unfortunately, just like breadboards, that crimping connection on the standard headers do begin to loosen up with repeated use.

That being said, we do carry development boards with PTH pins. Here are the ones that have the standard Uno pin layout:

This is exactly the difficulty engineers have with predicting product sales, and I've fallen for the same thing myself. When you've been soldering an constructing electronics your whole life things like soldering headers seem trivially easy and of course the customer can do that. I've been to some maker events where someone gets a bunch of people together to solder 100 boards with just through hole components, and I was able to build the boards five or six times as fast as most of the people also I was fixing supposedly finished boards to get rid of the obvious random shorts etc. So you have think about what a person with a lot of interest but an average skill set might be able to do. And I also see a lot of people coming from a software development background and they just want a no hassle way of putting together a bunch of modules to get some IoT device they can develop code on.

I tend to prefer boards without the headers pre-soldered. Many times I'm trying to get to a semi-finished product and I'm not trying to simply prototype/experiment with the board. Leaving the headers off lets me choose to:

1) direct solder a wire to the via 2) add male pins to just the vias I'm using for the project 3) add female headers to the vias I'm using for the project 4) populate all vias with either kind of header

Leaving them unsoldered is the most flexible way to do it. Though some might complain about alignment issues or the fact that they don't have a workbench, the truth is that neither should be a big deal. This is about technique - not technical skill that some don't possess. Place male pins into a breadboard in the positions you want to populate. If you want male pins, place the board on the previously placed pins and solder them in place. If you want female headers, put the female headers onto the previously installed male pins, add the board on top of that, and then solder the connections. The breadboard will hold everything in alignment for you. The only caveat is that you might need a set of double length male headers for placing the female header, but that's fairly uncommon in my experience.

Others may fear being inexperienced with soldering. That is simply a matter of 'seat time' - with some practice the above process will take you less than 5 minutes and you'll have perfectly aligned headers.

I'm fairly new to electronics (about 6 months), but I've learned to solder and can do a decent job at it. I also have a pile of headers (both male and female) that so that I have them when I need them. However, considering that pretty much everything I've done has either been in a breadboard or prototype board, if given the choice, I'll buy a board with headers every time, as long as it's the same price or maybe a couple extra bucks. Though there will probably come a day where I won't want headers, so it would be nice to always have an option.

The best for me (and alas, probably the worst to manage) would combine the ever-popular headers-in-the-bag with an add-on "solder them for me" service.

Yeah - I'm pretty certain that there's fulfillment and staffing headaches there. But some days it would be super awesome (apologies to Sylvia) if I could have the headers soldered for around $2/item (straight .1" headers) or $5/item (annoying smt things), or maybe $15 (.1")/ $25(smt) for an order (order goes to "soldering" between "picking" and "shipping" - maybe less of a workflow hassle than per item?)

The Photon has a really nice flat surface on the back with no components or traces - this is great for some double-sided tape to attach it to a project. I buy all mine without headers for this reason. Please don't stop selling them without headers installed. Thanks.

For my projects, I prefer to connect to the board using jumper wires, onto the pre-soldered male headers. I would have to solder if I was building something that vibrated, but that is not usual. This gives me the option to deconstruct the project when I am tired of it, and build something else with the same board. For example I am still re-using a microcontroller I bought from Sparkfun in 2010 !!

FWIW, I generally prefer to have headers soldered on and I will pay a few $ for it. Can I solder, yes, but I'm not that good at it. Any soldering project involves a lot of checking to make sure I didn't leave any solder bridges and connected the things that need connection. So, I would rather order stuff with headers attached.

Definitely prefer the Photon with no headers. Taking out the headers especially on this board is a complete pain. If you bought a Photon with headers and want them out read this post https://community.particle.io/t/desoldering-photon-pins/18172

I would be more than willing to pay a little extra to have those pins soldered on my as my vision is not that great anymore. I have screwed up quite a few SparkFun products trying to solder them myself. Please give us this option!

Headers in the bag but not soldered for me. If you don't want to include them, maybe your web team can include a link to the proper headers needed when new items are listed? That way the people who don't have a stash of headers at home (and really, for the price who doesn't?) are reminded to add them to their order. Also maybe a picture showing different applications of headers like you did with the Sparkfun Thing board...a combo of straight and right angles would be helpful. I didn't think of that and I pay the price when it's in a breadboard :-(

Thanks all for your thoughts on this! I did a really quick tally of the results. Note that I upvoted tycen's comment pasted below because this is not a scientific survey ;o)

46% - Headers (in the “bag” but not soldered on)

21% - Both options available (headers and no headers)

15% - Headers (soldered on)

13% - No headers

5% - No headers (but provide selection of header options)

Note that quite a few commenters conceded that addressing this issue would include some tough business decisions. Just the same, it was great to hear all of your feedback.

I'm a bit spoiled; I'm likely to have any header I might need, and I've got a Metcal desoldering station If I don't like the pre-installed header and want to use something different. I say that to help you understand what kind of customer I am (I doubt I'd fall into the typical category...). That being said, I doubt I'd pay an extra $1 to have headers installed on a $10-$20 board. I love it when the headers are included and not soldered, because digging around my header box to find what I'm looking for just reminds me how unorganized I am. If the price was the same with headers installed and not, I'd buy it with them soldered just because I feel like I'm getting a better deal.

Why not use the store to provide the customer to 'taylor' their purchase. The first drop down shows [soldered headers, headers included, no headers] and the second option, if applicable, [shows male, male/female]. This type of tayloring could simplify the entire store for an easier customer experience. I think this is important because why have two product links? In addition, you could list one product for headers and allow the user to taylor the length, etc.

I prefer both. Headers included for prototyping and without headers for final versions. Although some of my projects I just use female headers and plug the photon in the board so I can remove it later if I want.

No header pins installed, and maybe a set of loose header pins included, would seem to be the most flexible option. Depending on what I want to build, I may desire to solder on pins that fit into an IC socket, or maybe I may want to use long pins that stick out both ways, or maybe female header or some male-female combination like what we see on Arduino shields. Or just solder on wires.

Having to desolder existing pins is always fraught with risk, and it should not be necessary to do that. Having to solder in pins or connectors or wires or whatever happens to be desired right here and now is much preferable.

I am definitely in the "no headers" camp as it gives me ultimate flexibility. But I also understand people who are beginners wanting to experiment and soldering doesn't come easy to them. So I would say have both.

The correct answer is always both.

The first version of a board you try should always have header pins pre-installed on it, until you know how the board behaves well enough to understand if your soldering job is at fault for a circuit's misbehavior. Once you understand the board, you use it to prototype a project.

Sometimes, when you've got a particular project in mind, you want to prototype with particular types of headers attached. So your next boards you will want headerless.

When you've finished prototyping a project, and you want to install a board into a project in a finished form, you'll again want a board without headers attached. So you'll buy another board without headers attached.

As you finish more and more projects, you'll eventually use more boards without headers than the ones you prototype with... unless you accidentally destroy or lose your prototyping boards.

New boards are always going to start out header-heavy, in order to guarantee they can be experimented with properly. But the mark of a useful board is that the number of headerless boards will rise during the lifetime of the board, rapidly outpacing the headered boards, because it keeps being permanently installed into projects. It's not the "total sold with headers vs. total sold without headers" over time that matters... It's those two numbers over time that you need to track.

Also, it's important to remember that Arduinos completely throw off your numbers, because most newbies only come to SparkFun after they've already learned a thing or two, usually with some other Arduino. Another thing that will throw off the numbers is, the fancier the components, the more likely someone is to spin their own board for a complete project rather than solder your board down, just because the expertise they are required to have to use that component allows them to.

In regards to those thinking it's hard to find the correct header, maybe it is not clear to many people that for these .1 headers, you can cut a larger header into pieces as necessary for the correct pin counts. (they cut easily with standard wire cutters and they are scored in the right locations, so it's difficult to get it wrong) I often buy high pin-count headers and then chop them up for use across several different breakouts, connectors, etc.

You can break them by hand, and the break will be clean and neat. (They are build to be broken by hand).

I usually only buy those with headers installed. I hate having to source the headers and buy them. I can solder since I was eight, but I usually only buy things with headers. I am always plugging them into breadboards and building prototypes. I hate to do it myself and I am always worried that this time I will mess up the board--never do but still possible.

I love both options. But like the idea of headers I. The bag but I can buy a ton of headers for a few bucks so whatevs. How bout a mix of male female and right angle? Boom!

I've been wishing for two things for a while now. 1) That there was an option to purchase Pro Mini boards with headers pre-installed (just down the two rows, not on the FTDI pins... or solder those pins on the top side), and 2) there was more of an ecosystem for Pro Mini boards (by this I mean, make shields for not only the full Arduino Uno, but for Pro Minis as well... kinda like what Microduino did.

What would also be nice, is to offer Pro mini boards with headers, and to offer a "Pro mini to Arduino shield" adapter, kinda like the Microduino Uno adapter shield (https://www.microduino.cc/product/uno), but for Pro Minis.

I want to chime in on this because I have done both. I have even desoldered the pins from an Uno to make it fit in a prototype. Maybe try sending a strip of breakaway headers with orders over $5?

I think of most stuff sparkfun sells as a dev kit. I rarely if ever embedded a BOB, dev board, etc into a final project. I produce my own boards for all final products. With that said I prefer the header pins on the board. I can quickly de-solder them when they are in my way but I really like a breadboard footprint with headers for all my dev boards and breakout boards. Bare minimum throw the headers in a bag. I find too many time I'm short 1-2 pins in my stash of headers laying around in my lab to complete a board when i really need it. It is a convenience of not having to look around the lab to find pins or scavenge them from something. When I open the bag if they aren't on the board and aren't in the bag the dev kit might sit unused for a long time. Soldering a bunch of wires on to prove in something just isn't why i buy a dev kit or breakout board.

I prefer headers in the bag as well. This gives me a range of options that includes breadboard prototyping, building circuits, etc.

If its a new board, where there are unknowns about how it fits in to projects, if it will have enough support and community, and if its a larger more dev-kit-like board, then I would want headers. If its a known platform, its a great fit for embedding in to projects / replaces some previously larger or less powerful board, no headers is good.

But as another comment suggested, having them provided with a headless version would be helpful.

ps. would pay a couple bucks more for headers on

Usually I prefer to solder in the pins myself, so that I can customize the configuration. But I can see where pre-soldered headers is beginner-friendly.

Include the headers but don't solder them into place. Sometimes I want to use a different style of header, or none, so they have to be removed anyway. Plus boards usually survive shipping better without the headers attached.

Include the pins in the bag, but leave them unsoldered.

I've messed up the soldering of headers more than once. I would still prefer the flexibility of doing it myself: proto versus final and headers versus pins versus wires-a-plenty. Also, I use displays and those really need to be on top.

I'm getting used to digging myself out of self-inflicted messes.

Cheers!

I think its also fair to mention that the option without the header allows you to solder it directly to another board, kinda like a SOC., This not only reduces the overall height of your project (Miniaturization) but its also allows you to permanently attach your board, an use a braid to remove it (You don't have to solder though the pin holes).

Having the headers included is not a concern for me as i have tonnes lying around (i make headers only orders from time to time) cause i use headers on boards i design myself.

Its fair to note that even with the headers included in the shipment, some folks don't want the job to solder as they are only creating a prototyping setup to prove a concept and may even move away from the arduino (or other) form factor for the final product. If i can remember correctly, there is a type of header that allows you to snap the boards on and remove after, its holds like a solder joint but without solder (don't remember name). Also i think i saw it on this site. Maybe a good option to start exploring and making better use of those. Funny, they are called solder-less headers, but they are retired (wonder why). https://www.sparkfun.com/products/retired/10527

The solderless headers didn't sell well and were horrible to use. The name sounds great, but the amount of pressure needed to connect those to a board was baffling. They were also meant as permanent connections so once they were connected they were even harder to disconnect. Even if you were able to, the pressure while inserting and removing these along the inside of the holes would quickly remove the contact. In other words, they sounded amazing based on the name, but the implementation was actually more headache then it was worth.

The thing I like about headers is that it makes the part replaceable. I tend to assume that I'm going to screw something up and plan accordingly.

I like being able to choose between the two options. I'd be willing to pay $1 to have someone solder the headers for me. At $2 or more, I'll do it myself.

I thought it was dumb for you to offer the SAMD21 Dev Breakout DEV-13672 without the sockets/headers included. This board seems like a drop-in replacement for the Arduino Zero (or the .org M0) for users who don't need EDBG. I could see if you included them "in the bag" for customers to solder on but it would be worth a few bucks more for it to come ready-to use.

Just my simple opinion.

have you seen the DEV-14812?

No headers for me.

It depends.

Am I planning to use this on a breadboard, embed it in a project, or both? Do I feel like hauling my soldering iron out of my closet and setting it up just to throw on a couple headers? How big is the price difference?

Sometimes it's nice to have options.

I think the best of both worlds would be to sell the boards without the header pins soldered in, BUT to include the header pin strips with the board. The best way to attach the pins is to plug them into the breadboard and then set the PC board onto the pins and then quickly solder the pins onto the board (quickly so you don't melt the bread board!). This way they get attached nice and straight!

Note that some of your boards have extra pads to access IC pins that are NOT brought out to the breadboard pins, IE: the Arduino pro mini allows access to the SPI pins and two extra Analog inputs that are NOT at the board edges.

The Teensy 3.2 is even worse, there are almost as many I/O pins on the bottom as on the edges! (Someone does make a special adapter to get to all of them that DOUBLES the number of breadboard pins! Wish you carried it!)

Agreed.

Other random thoughts: I recently bought some FTDI serial to USB (not from Sparkfun) which were shipped with the headers but I had to solder them on. That was better than having to add them to the order. If I'm going to be buying a shield for an Arduino there is no reason I'm going to not have headers on it. I also think that even if it has headers its not hard to solder wires on as well in the event that you need to.