If you haven't picked up on the sarcasm in the title, this is going to be a dry blog post. I'm working on something cool with asset tracking for next time, but didn't have it ready for this turn. So today, let's go over the ins and outs of finding a connector that works for your design.

It annoys me to no end to see incomplete projects. I love when people share what they've made with our parts, but hate the jumble of wires sticking out of a breadboard in an incoherent mess on someone's desktop. Don't get me wrong, you've made progress and that's awesome, but finish the project. Now there's a ton of ways I would suggest finishing a project, but the biggest is – USE CONNECTORS!

Connectors are here to make life easy. Yes, it requires assembly and soldering. But at the end of the day, it gives your product a finished/professional look and will greatly increase its lifespan. I can't tell you how often I see people fumbling with homemade wire harnesses at shows and events because a solder jointed popped or a kink in the wire has caused issues (things that can happen with connectors, yes, but in my experience much less when you use them).

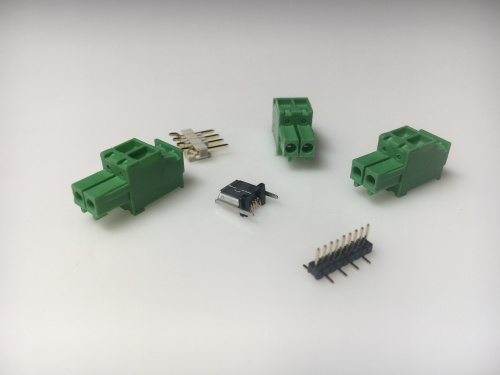

Small variations on popular connector types

There are many reasons people don't like using connectors. If you're soldering anyway, why add an extra step with a connector? And of course the issue of all issues – it adds cost to the project. But the one that irritates me most is the complaint, "None will work for my project." The interconnect market worldwide is huge – $39 billion (USD) a year. There's the standard connectors you know and recognize. Then there's thousands of less known connector styles that could very well fit your needs. Some might need to be soldered, some require unnecessarily expensive crimp tools, but there are a multitude of variations that should meet your needs. However, this brings up the question, where do you find them?

As part of my role at SparkFun, I have regular meetings where a manufacturer rep will come to the office and bring cases of their products (more often connectors, but occasionally ICs and sensors). Having access to this and having to source connectors without seeing them, I have to say, it's much easier when they're sitting in front of you, but that's a luxury most do not have. You can still get evaluation units but finding the type that works for you is still difficult online, so below are some tips I have for finding the right connector.

Know the correct terminology

Do you know how many times I've said to myself, "Oh, THAT'S what they're called!"? Knowing the correct terminology for the connector and what it does helps narrow your search and brings up new sources you might not have found before. The biggest are these three: Board to Board, Board to Wire and Wire to Wire. Knowing these three terms and what types of connectors they refer to helps narrow your search dramatically. Each describes the connection being made: Is it connecting boards, wires, or wires to a board? From there, there's a number of different descriptive words that can be used to narrow the search further. For example, features like polarized, surface mount, right angle, etc. (this example list is comically small in the interest of time). At this point, you're able to start generating lists small enough to go through dimensional drawings or pictures. Don't be afraid to ask about terminology. Very few people could give a definitive descriptive name for every connector type, so there's no shame in asking (not that there ever is, but some people feel embarrassed about doing so).

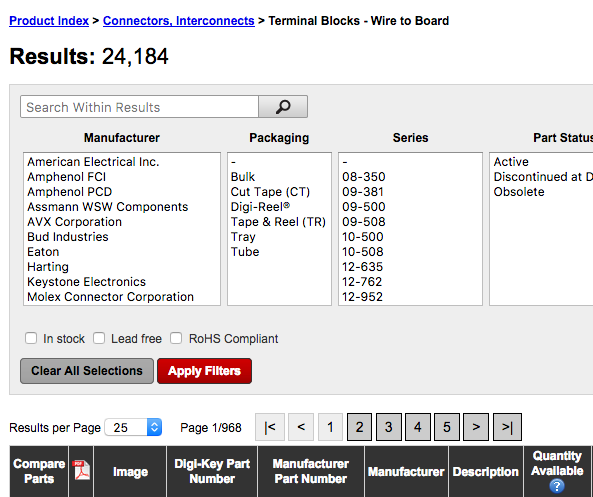

Comparatively, this narrowed the search down by a lot!

Having your needs down

The number of pins, the size, and the electrical properties are the next things to look at. Connector families will usually have a landing page, whether it's on the manufacturer's site or retail sites like Digikey. On these pages will be general characteristics of the connector family; this is going to let you know at a high level whether this connector is going to work for you. But that's the easy part. The hard part is figuring out what you're not thinking about (easier said than done, right?). Think about what environment this connector will be used in. Is it a more permanent connection, or will it go through a lot of plug-unplug cycles? Is there a chance it will be exposed to water? Will there be a lot forces acting on the connector (does it need be reinforced)? Like I said, this seems so simple, but things like this often won't be figured out until you have it in use. SparkFun has learned this lesson many times.

Keep your options open

Even when you find what you need, there could be competing companies making similar products. One could be cheaper; one could have a more favorable configuration or feature – evaluate all options. I understand this is getting a bit involved for something you're going to spend very little money on, but you might find a set of connectors you want to use on all of your projects. As an add to this, most companies will do custom variations of connectors if the quantity is high enough (useful if you plan on going to market).

Look outside the big companies

Companies like Digikey and Mouser have almost everything. While starting with them is the best way to evaluate a bunch of different brands all at once, there's some they don't stock or carry. Be ready to look outside those companies to the actual manufacturers. This goes back to the knowing the terminology part – if you can put the right keywords into Google, you're likely to get a good lead on the first page of results. In that review of the connector industry above, the top 10 companies account for 50 percent of the total market revenue, but the second half represents hundreds of smaller companies.

Have an open mind

There are a lot of factors - some we've covered and some we haven't - that could dissuade you from using a specific connector. But keep an open mind. Your concern about the pricing could be easily canceled out by the ease of use or ability to customize pin locations. Think of it like playing with a new dev board or microcontroller. There's a lot of pride these days in finding handy parts; you'll never find them if you don't give some a chance.

Deutsch makes one of my favorite families of connectors (photo courtesy of Amazon.com)

SparkFun isn't in a position to carry a multitude of different connectors, in fact most resale companies aren't. You'll see a ton of 0 stock parts with the bigger component companies. If they can't, we definitely shouldn't try. So really what I'm suggesting here is shopping for connectors somewhere else besides SparkFun. Sure we're going to have a lot of the standard connectors that work well with development boards like Arduino and Raspberry Pi, but adventure out. Find a connector that is going to work well and keep your project running and intact. Additionally, if you have a family of connectors you love to use, point them out in the comments.

That Deutsch connector looks neat. I'd love a list of links / model numbers for connectors that the SparkFun staff likes to use! I think that'd be a great jumping off point for most of us

I usually go to Waytek Wire for a shortcut into rugged connectors. They stock an Amphenol product that is compatible with the Deutsch DT and DTM series. They also have crimpers for machined contacts for about $30 instead of the $400 standard crimper.

Here's the amazon listing I borrowed the photo from.

The reason I'm so into their connectors is I got to use them when working for an endurance race team. The connector I was using had 8 positions and it was easy to put the pins in the configuration they needed to go. With these connectors, a wire stripper, zip ties, and the crimp tool (probably not cheap) I had put together an entire wire harness for the lights on the spare hood in about a half hour. Those lights ran the rest of the race without problem (~14 hours).

In HAM radio I find the Anderson power pole connectors as something of a standard for 12 volt applications. They are sturdy and the specialized crimp tool can't be beat. They have the useful property of being hermaphroditic. The common usage is red/black but other colors are available.

If I was a new maker, I would start by getting a Molex Universal Crimper, $55 or less, and an assortment of Molex SL series connectors. From experience, I would advise folks to stay away from connectors more than 8 circuits wide because of high insertion and removal forces. It is not much of a limitation for makers as, 2 rows of 8 is 16 circuits which is a lot of circuits going to just one place. The Pins and Sockets are reasonable and pretty well stocked by the usual suspects. As a bonus, the contacts are compatible with 0.1 header so they can be used to make custom male and female jumpers in a pinch. There is a large variety of shells of every shape and size mate wires to wires, wires to boards, and wires to panels.

Personally, my tool box has Deutsch DTM and DT series connectors, Anderson Power pole in the 75 Amp and smaller body style, Sub-D connectors with 9, 15, and 25 circuits, and a large assortment of PIDG terminations especially the ring terminals.

I keep Deutsch DTM and DT Series connectors on hand for working on my vehicle. They are a great combination of affordable, easy to work with, and rugged. They also offer some premium options such as macined pins and sockets for higher current applications. Recently I've found a number of 4-way and 8-way indent crimpers at the sub-$50 price point that do a good job of crimping the machined contacts.

I use Anderson power pole for weather protected higher current DC applications. These can be had in a kit 20 or so connectors and a crimp tool for less than $100.

Sub-D connectors can be had for very cheap. All of the usual suspects stock parts, though I've found several small retailers keep a better stock at lower cost in small quantities. It is easy to find variants that are weatherproof and you can be reasonably sure that it will mate with the pieces you have knocking around in the used parts bin.

One last thought. I hated connectors until I spent several years in industry. My time in industry taught me that what I hated was bad connections. I learned how to prepare a crimp, and that my 50 cent garage sale crimping pliers did not produce a proper crimp. Ever since getting a good but not exorbitant crimper, I'm very happy with my connections.

I don't know about you, but when purchasing a new crimper I usually am willing to pay a modest premium to get a ratcheting crimper. Not only are the ratcheting crimpers usually better quality, but I have much more confidence in a crimp pressure that is defined by the ratcheting cycle rather than subjective feel.

Coming from a pinball background, I got used to the Molex "KK" series 0.156" board to wire connectors. They're cheap, versatile, reliable, durable, and have plenty of options. For my fancy stuff, I used the gold plated pins and gold plated "trifurcon" contacts. For everything else, the ordinary tin ones work fine. For smaller stuff, the ordinary 0.1" square header pins work fine, and there are plenty of options for plugging onto them. Both of these sell the receptacle housings and contacts separately, so you assemble the contacts onto your wires and then put the contacts into the housings, where they lock into place. There are also IDC options available. I was pleased to discover that for board mounted antennæ, the u.FL connectors have become sort of standard. I use 'em for WiFi, Bluetooth, GPS, cellular, etc. It's easy to find inexpensive antennæ with those connectors already on them, and there are adapter cables to other common connectors (BNC, SMA, R-SMA, etc.).

Another trick, especially with pin headers, that many people don't know but would make set-up much easier is to have an unused pin in the middle of the header. When assembling one clips that pin. And on the mating connector (pin header housing for board-to-board, or IDC connector for board-to-wire) block the hole that corresponds to the clipped pin. Now the connector can only be inserted one way because it has been keyed. Many IDC connector sets have as part of the product family little plastic plugs just for this.

(I wish the FTDI cables were originally designed with this feature. Much easier to look at pins for the missing one and line the plug up with that position than to try to scry the orientations from markings on a board, especially when the board itself is nearly hidden from view.)

This trick can also work with just about any connector type that uses crimp-and-plug contacts. (Though on some connectors this is just plain silly because the connector bodies provide the keying mechanism.)

Speaking of ridiculously priced crimpers (for ridiculously priced, MIL-Spec/aerospace connectors) look at the line of DMC turret crimpers. The tool (just the handle and crimping mechanism, you need either a turret or positioner to hold the contact in the correct position inside the crimping mechanism for you) run in the $250 neighborhood. The positioners and turrets run in the $50-$150 range. But DMC actually does provide a full kit that has both tools and all the turrets and positioners that you should need for the low, low price of $4200.....