You ready for some photos and videos? AnnDrea told me that pictures should not be a tutorial, so let's see if I can break the home page...

The Geek Tour traveled to a handful of factories and facilities in Shenzhen, China that

made plastic enclosures, Velcro, shoe laces, PCBs, kitting, assembly,

and fabrication. How did this tour come about?

Suited up for the tour!

Bunnie Huang (in the middle) works for Chumby. Cumby wanted to get their device made, so Bunnie started looking for a company that could build the Chumby (a rather complex device). The problem is that there is no one factory that could build the device from start to finish. Instead, Bunnie discovered PCH - a company that gets all the parts made from various manufacturers and gets the final product delivered. PCH is run by a handful of wonderfully fun Irishmen. Joe, Liam, Baz (Melborne!), and the rest of the PCH crew where fantastic in taking care of us and showing us a fair and balanced view into what it takes to 'get a widget made'. The following is a fairly brief collection of pictures and videos from the trip. It was truly eye-opening.

Don't leave yet, there's tons of photos. But for more, checkout:

Most of the following photos where taken by Joe from PCH. We were not allowed to take a camera because of NDAs. This was actually a good thing because I spent so much time looking and trying to keep my jaw in place that taking pictures would have been hard. Joe did a great job!

Imagine machines that make 280km of velcro a day. That's 10 feet of velcro as second. One factory, 10ft of velcro a second. That was the China trip for me - just trying to wrap my head around the shear volume of materials and products being made.

Molds! These are steel tools for creating plastic enclosures. Hot plastic is forced into the chambers to create a given part - like the housing on your remote control.

Rather large and expensive - price ranges from a few $1000, to tens of thousands of dollars. This is a very complex mold.

Lots of molds! Because of their expense, size, weight, they usually stay in the factory. Many companies consider these as physical manifestations of their intellectual property (IP).

How do you make a tool out of a solid block of steel? You mill out a cavity, then use an EDM to electrically remove the smaller, more fine bits. This machine is routing the copper electrodes that will be destroyed in the EDM process. It's subtractive, so if you want a rectangular hole, you make a rectangular electrode. The array of electrodes above will soon be holes in a block of steel. The EDM machines 'push' the copper electrode into the block of steel. We saw gauges reading 220V and 10 to 20Amps! A lot of power. The process is slow: a 'quick' steel mold can take 6-8 weeks.

Now take those molds and make stuff! These are the injection molding machines. I believe the number I heard was 1 billion pieces per year. That's a lot of enclosures.

Inking machine. Secondary process after the piece is cooled from molding.

Picking up ink.

Transferring ink to the part - cool!

The next trip was to a PCB fabrication house. This was my second trip to a PCB fab house after Olimex. This was a much larger operation. Here's a layer of a motherboard? coming out of a laminating machine. The layer is surprisingly flexible at this point.

Geek Bond. I wonder what you do with that.

Tons and tons of copper boards. Here they are curing after getting laminated to the base FR4.

How do you drill 20 million sq meters of PCB per year? With 6 drills going at the same time. The room had 12 of these machines.

The machine kept track of bit usage and damage. If you look closely in the lower right corner, this drill program was running for 1:30:47, that's one and a half hours! These were very fast machines, but this was a wickedly complex board. How does a motherboard, with components cost $50? They build a lot of them.

Drill bits. I think they were 0.8mm. A 31mil hole is actually pretty large on my designs. My holes are normally 20mil (0.5mm)!

Yep. That's a lot of holes!

A board later down the line in the etching area.

A huge mass of the board (video card pictured above) getting transferred from one dip tank to another.

Fun chemicals for etching away copper and plating vias. Boards are robotically picked up out of the vat and moved to the next vat.

This is electroplating at its best. Notice where the arms hold the boards, they get plated as well.

Pulling the boards off the end of the vats. After the last dip, the robotic machine pulls the boards and lowers them so the workers can rack them for the next step.

Lots of boards!

After the boards are made, they have to be tested.

Testing machines. Every PCB design has its own test bed of nails.

That is the mother of all pogo beds. Every PCB has to be tested for every connection. While I was watching one station, the bed started failing boards. I watched as the operator pulled out a single pogo pin, insert a new one, and start back up within seconds. I guess the pins wear out over time?

Where else would you see CNC advertisements on a building? Only in Shenzhen!

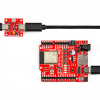

Blazingly fast pick and place machine!

Faster than our pick and place (but not nearly as cheap)!

To get an idea of the scale of the assembly line. No too long actually, and the boards simply never stopped.

Ok - now to a PCBA (printed circuit board assembly) facility. They're making a power supply for a printer.

All wired for ESD.

Fluxing the IC like clock work. This worker added flux around two SMD ICs on the bottom of the board (that must have been glued) and a few through hole components. The flux allowed the SMD component to get soldered during wave soldering.

Mostly through-hole, with some SMD components on the bottom of the board. Notice the chunk of metal on the board (circular gray dot, just left of center). That weight is holding that component down so that it doesn't raise up during the wave process...

That is a molten wave of solder. As the boards pass over, the bottom of the board is soldered all at once and the board moves across the wave. I've heard these machines are very hard to setup and get working correctly - but once operating, they can solder a tremendous volume quickly.

After the board came out of reflow, some of the legs of the PTH components had to be clipped off. She is actually hitting the same spots on each board, just very quickly.

Here the workers are doing some secondary through hole soldering - pretty quickly, but I am proud to report our guys in production move this fast (just not with such repeatability)!

Entertaining sign.

A bag of raw material in the plastics market. That would read 'China Nuclear Huayuan Titanium Dioxide'. Oh ya, that. I need a 25kg bag of that.

And if I'm shopping for resistors, I might as well look for shoes while I'm at it.

Neat building.

Here's the goodies purchased from the electronics market. Let me roll through some prices to give you an idea:

Yes! Design T-Shirts, Store graniph? There were shirts like this all over. Imagine what the Chinese think of our tattoos. Sure that symbols means tranquility...

Inking machine. Secondary process after the piece is cooled from molding.

Picking up ink.

Transferring ink to the part - cool!

The next trip was to a PCB fabrication house. This was my second trip to a PCB fab house after Olimex. This was a much larger operation. Here's a layer of a motherboard? coming out of a laminating machine. The layer is surprisingly flexible at this point.

Geek Bond. I wonder what you do with that.

Tons and tons of copper boards. Here they are curing after getting laminated to the base FR4.

How do you drill 20 million sq meters of PCB per year? With 6 drills going at the same time. The room had 12 of these machines.

The machine kept track of bit usage and damage. If you look closely in the lower right corner, this drill program was running for 1:30:47, that's one and a half hours! These were very fast machines, but this was a wickedly complex board. How does a motherboard, with components cost $50? They build a lot of them.

Drill bits. I think they were 0.8mm. A 31mil hole is actually pretty large on my designs. My holes are normally 20mil (0.5mm)!

Yep. That's a lot of holes!

A board later down the line in the etching area.

A huge mass of the board (video card pictured above) getting transferred from one dip tank to another.

Fun chemicals for etching away copper and plating vias. Boards are robotically picked up out of the vat and moved to the next vat.

This is electroplating at its best. Notice where the arms hold the boards, they get plated as well.

Pulling the boards off the end of the vats. After the last dip, the robotic machine pulls the boards and lowers them so the workers can rack them for the next step.

Lots of boards!

After the boards are made, they have to be tested.

Testing machines. Every PCB design has its own test bed of nails.

That is the mother of all pogo beds. Every PCB has to be tested for every connection. While I was watching one station, the bed started failing boards. I watched as the operator pulled out a single pogo pin, insert a new one, and start back up within seconds. I guess the pins wear out over time?

Where else would you see CNC advertisements on a building? Only in Shenzhen!

Blazingly fast pick and place machine!

Faster than our pick and place (but not nearly as cheap)!

To get an idea of the scale of the assembly line. No too long actually, and the boards simply never stopped.

Ok - now to a PCBA (printed circuit board assembly) facility. They're making a power supply for a printer.

All wired for ESD.

Fluxing the IC like clock work. This worker added flux around two SMD ICs on the bottom of the board (that must have been glued) and a few through hole components. The flux allowed the SMD component to get soldered during wave soldering.

Mostly through-hole, with some SMD components on the bottom of the board. Notice the chunk of metal on the board (circular gray dot, just left of center). That weight is holding that component down so that it doesn't raise up during the wave process...

That is a molten wave of solder. As the boards pass over, the bottom of the board is soldered all at once and the board moves across the wave. I've heard these machines are very hard to setup and get working correctly - but once operating, they can solder a tremendous volume quickly.

Here the workers are doing some secondary through hole soldering - pretty quickly, but I am proud to report our guys in production move this fast (just not with such repeatability)!

Entertaining sign.

A bag of raw material in the plastics market. That would read 'China Nuclear Huayuan Titanium Dioxide'. Oh ya, that. I need a 25kg bag of that.

And if I'm shopping for resistors, I might as well look for shoes while I'm at it.

Neat building.

Here's the goodies purchased from the electronics market. Let me roll through some prices to give you an idea:

- AVR Programmer: $35 (250 RMB)

- Perf board: $0.5 (5 RMB)

- Multimeter: $8 (55 RMB)

- Iron: $6.50 (45 RMB)

- Batteries: $1 (8 RMB)

- Hand tools: $2 (15 RMB)

- LCD: $4 (30 RMB)

Yes! Design T-Shirts, Store graniph? There were shirts like this all over. Imagine what the Chinese think of our tattoos. Sure that symbols means tranquility...

You ready for this? That's me (Nate), in a Bug Labs t-shirt, having a drink with Eric from Seeed Studio. Talk about a collision of worlds! Through a wild series of coincidences, SparkFun and Seeed Studio got to meet. Eric is a incredibly smart, well spoken, engineer and businessman. It was a pleasure to meet with him and have some great discussions on open source hardware. Eric also helped me out a ton navigating a second run through the electronics market.

Hi friend

really nice pictures,thanks for your always supportting,hope next time you could give me a call when you at shenzhen.

Re: pogo pins... yeah, they wear out. Not sure if it's mechanical wear or oxidation, both, or something else but eventually their conductivity is suspect. They can also misalign over time if they contact something that isn't perfectly flat (solder bump, etc.).

I love the pictures of the soldering machines. No wonder most of the devices are manufactured there.

Can you please fix the Flash video code in these posts so that they don't show the Flash + a broken embedded object in IE7? I know, don't use IE7, but it'll help make it more standards compliant anyway. Here's a good method for doing this:

http://perishablepress.com/press/2007/04/17/embed-flash-or-die-trying/

Wow... I know why the visitors to our sites boost since last night. Thank you for introducing us with such high comment!

An view from my side: People here are professionally used to traditional massive production, where profit margin is slim with huge qty. Economic recession has frozen down many factories, a lot of people lost their job leaving a semi-empty industrial region. Some of the survivors has to consider small or tiny orders, which is great for niche market product in the other way. It might be a great time for the sub market, well including open source hardware projects. :)

And, I have never got a chance to shoot in the factory, Great records indeed!

Hmmm. The funny T-shirt is by Japanese company http://www.graniph.com/ .

Has the same font as American Apparel. I wonder if they are related?

I am so incredibly behind the fashion times! Thanks SSCI. I didn't realize it was a legit shirt. Very cool tshirt designs.

After today's story about Mattel skipping US entirely & focusing its retail stores strictly in China, we're grateful that you continue to sell parts to US. No doubt you would reap bigger rewards a total electric parts economy like China.

While "Titanium Dioxide" sounds scary, it's actually all over the place. In fact, most people eat a good deal of it yearly. I worked in a frosting factory when I was 19 and I used to dump 25lb bags of it into tanks full of vanilla frosting. It's used as a white food coloring and preservative, and makes the frosting whiter. It's also used to whiten skim milk. So...Bon Appetit! Oddly enough, it's also a pretty good semiconductor and is often dumped on unsuspecting actors when studios need to shoot a snowy scene and have no actual snow.

China Nuclear... confusing translation, it means the company is invested by China Nucluer group. Some relation to Nuclear heads? @__@

Nate, I'm blown away. Thanks for sharing these images, videos and experiences with us.

How do you think this will all affect Sparkfun

- will you be offering a greater variety of components you found in the markets there?

- improved manufacturing of SFE modules?

- higher volume?

- BatchPCB changes/improvements?

What do you think the biggest impact of the trip will be on Sparkfun and its customers?

Thanks again, Nate.

Landon

Awesome questions!

1) We're always looking for cheaper and cool parts, so yes, you'll be seeing more small stuff from Shenzhen.

2/3) Even getting as big as we are, production is still in-house. We're more flexible, faster, and at the moment cheaper than anything we can have done in China.

4) We're working on quicker PCB turns for BatchPCB. Shenzhen and China in general is still focused on mass volume - and that's ok. But I think within 5-10 years, the manufacturing world will start to realize the ideas of the long-tail and user brewed innovation. Short run manufacturing will make economic sense sooner rather than later.

Hi guys,

I love all the cool stuff you guys have put together.

I live in Shenzhen, so if you need help getting products or components just let me know.

I go to Hua Qiang Bei (the big electronics market in Shenzhen) all the time to drool over all the gizmos and components for gizmos.

Tim S, we should hook up in Shenzhen and start a Maker's Club.

Cheers

Erik

Erik,

Could you please give some tips on the below:

1. how get samples from vendors from Shenzhen from the States? (I once contacted a vendor from www.globalsources.com, and the person wants $90 USD for 3 pcs of LED matrix. I told her that I am NOT that stupid!)

2. First-timers to visit Shenzhen? What are the tips on staying there, how to negotiate with vendors, etc.?

I have to ask, are the products they sell in their stores as cheaply built as the stuff they send to the states?

Also, next time you have a chance to buy 1K of LEDs for $5, buy them and send 990 of them to me. I will send you $4 and you have your ten for a buck. ;)

I think that was part of the fun - really didn't know what you were getting. The $6.50 iron worked surprisingly well, but not as good as my $80 Aoyue. The $1 wire cutters were the best I've ever used, but the $2 wire strippers were pretty crumby.

WOW! Great pictures and information. Next time you are in Hong Kong/Shenzhen let me know and I would love to go along. I try to visit the Shenzhen market once a month, but lately it has been like every two or three months.

From my experience of living in Hong Kong and working in China I can say this verify that this is how it is all over in the 10s of factories I have been in an visited as well. This is an interesting and mind blowing place to visit and experience.