SparkFun has a rich history of manufacturing, and I’ve had the pleasure of being a part of it for almost 11 years now. Throughout that time, we’ve given you some interesting perspectives on how we produce all the different variations of kits and boards in our facility here in Colorado. Today I want to give you an update on our processes and dive a little deeper into the "why" of what we do.

Let’s start with a high-level view of the things we make here at SparkFun. SparkFun manufacturing is responsible for producing three separate types of products, through three very different processes. These three product groupings are: boards, kits and packaged goods.

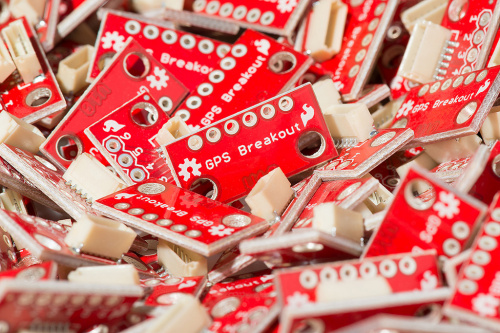

The first, and probably most recognizable - boards - has been a part of SparkFun since day one. Currently we are producing about 75,000 boards per month. Our final yield (number of working boards/total number of boards built) has not dipped below 99% for over two-and-a-half years, and typically hovers around 99.5%. This level of quality is achievable by truly believing and investing in our people and processes. We have a very talented group of approximately 17 individuals that all play a part in producing a SparkFun board. Equipment Operators, Final Assembly Technicians and Packagers all have vital roles in making a fully-functional, assembled SparkFun board that meets and hopefully exceeds customer expectations. We believe that keeping this entire manufacturing process within our control enables us to produce a better-functioning, better-looking and more well-supported product than other fulfillment options. That being said, the DIY electronics market is a very fast-moving one with new players and new technologies every day, and we will always continue to look for ways to improve our ability to offer our customers what they want (see: open source).

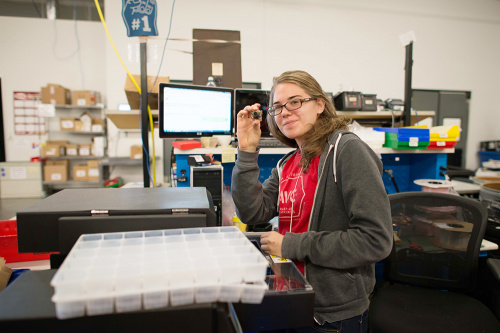

The second type of product we offer and produce in-house are our kits. Kits haven’t been around quite as long as boards, but are definitely a major contributor to the work we do everyday, and they continue to grow in popularity with our customers. Currently we are producing approximately 20,000 kits per month. Similar to board assemblies, our yield with kits has hovered around 99% for over two years, though this is achieved with a much smaller workforce - only six employees currently. Kitting differs from Board Assembly in the fact that it is a much more hands-on process. There are no fancy machines or robots placing tens of thousands of parts in a box or case - just humans. Again, we believe that investing in our people and constantly looking for efficiency gains within our own four walls enables us to fulfill customers' needs while maintaining control over quality and aesthetics.

Lastly, a look at our packaged goods. Over the years we’ve learned our customers want a complete unit of something, free of defects and protected from the elements to ensure its operation and usefulness, regardless of origin. Therefore, we have taken many of our raw materials components and added a simple packaging step to ensure our customers get what they paid for. There is no hiding the fact that we purchase many items from overseas. - things like arcade buttons, toggle switches, load sensors, etc. When we do buy these things, we usually buy them in the thousands.

Various vendors have their own ways of doing things to take advantage of the economies of scale. Take the arcade button, for example. When these buttons arrive they are separated into the button itself, the mounting ring and the internal mechanism that houses the electrical connections. Through our packaging process, we take those three separate items and pre-assemble them into a single complete unit. This completed unit is then packaged and individualized from all its brothers and sisters still in pieces waiting their turn. This process not only aids in some of our internal operations, it ensures that the product arrives to the customer complete, free of defects and ready to be inserted into their next great project. We haven’t tracked packaging numbers as extensively as boards or kits, but current trends show that we package approximately 25,000 items every month.

Our main philosophy throughout all three of these separate processes is to provide our customers with the best possible products while maintaining a focus on efficiency, quality and ability to support said products. We believe in what we do here at SparkFun, and will always strive for perfection in our assembled goods and complete satisfaction from our customers.