As we say at SparkFun, trying is cool, failing can be even cooler, and trying again is the coolest of all. Some of the best insights come from mistakes. The creative process requires patience and humor, so we asked a handful of folks around here about their biggest fails in the pursuit of project glory.

Rob

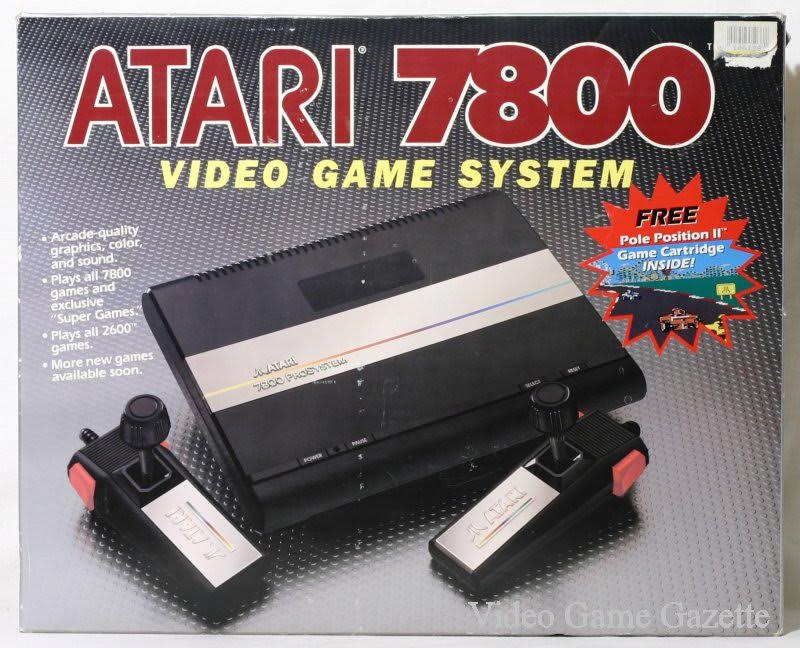

I bought an Atari from Craigslist and it did not work. Convinced I could fix it, I opened it up and found a few puffy-looking capacitors - I assumed that was the issue. I de-soldered and removed about half a dozen capacitors, then installed new ones. Apparently, in my haste, I reversed one when I put it in. But with an unjustified sense of flawless accomplishment, I screwed the top back on, plugged the unit in and hit the power button. I was immediately greeted with a loud pop and quite a sizable puff of blue smoke.

Mary

I have two at SparkFun. The first was when my piggy bank for the food drive "nope'd" out:

The second was when I made heated massage bunny slippers for the Haptic-Motor Hook-Up Guide. Moose did not approve.

Before

It's not like he had a bone to chew on or anything.

Toni

- Radiator replacement on my Jeep

- One tiny hairline fracture = coolant leak

- Read all the guides and gather the tools = one day

- One tiny $0.50 disconnect tool for the transmission line not listed in any guide I referenced = three days of biking back and forth to the auto hardware store to find the right one

- Finally replace the radiator and refill the coolant system = pure joy and one cool engine

- Drive the Jeep to the airport the next day, blow the gasket on the thermostat housing that wasn't seated *just right* = explode boiling coolant all over the engine at DIA

- Swear off car repairs = return to electronics (until the electronics require swearing off).

Jenn

I don't have pictures unfortunately, but two years ago for Halloween I tried to make a pin-up style dress that I put LilyTwinkles and LEDs all over to make the dress sparkly. I used a ton of conductive thread, had 14 twinkles and batteries sewn into the inside of my dress and I was trying to get everything hooked up and working.

It didn't work. I'd apparently wired in one of the batteries to the LilyTwinkle wrong, and was mere seconds from lighting the whole thing on fire. The Twinkle and the battery both got super hot, burned the hell out of my hand and scorched my dress.

There ya have it - it happens to the best of us. What was your biggest project fail (bonus points for photos)?

The year was about 1973 and I had just finished assembling my very own Altair 8800 computer (which I still have). It had a whopping 17K BITS of memory, a cassette data loader, a small keyboard, and an old black & white portable TV (neither Microsoft nor monitors existed). I had written (in octal!) and loaded (flipping switches on the front panel) a boot loader, which got the cassette to load the main code and yeehaw, the keyboard worked - what you typed appeared on the screen.

My girlfriend (now wife of 45 years) invited me over to dinner at her folks house. Not being one to turn down food, I packed up my nice new computer and took with me to show off to her family. One thing you should know is that houses built in the 1930's did not come with 3-prong power plugs as they do today. Oh and the tv? yeah it was a hot chassis, which meant that there is no common ground circuit. Of course when it was all plugged in and I hit the power switch, 120 volts immediately went to ground resulting in a big puff of blue smoke and bits of exploding capacitors went tinkling all over. Another two weeks of desoldering the IC's from each of the circuit cards (didn't know about sockets) and buying a complete new set of IC's and a Intel 8080 chip. I was back in business and answering the same question over and over; what can you do with a computer?

While I was in college about t&$@#e years ago, I spent a Christmas week at a cabin in the woods. I knew I would have little to do during the week, so I came prepared--I brought with me a considerable amount of balsa and basswood, cardboard tubes, glue, and X-Acto blades, so I could spend my time designing and constructing a model rocket. The design was quite complex; it was to launch vertically, as normal, but with the ejection charge the body would lengthen and wings would extend out so the craft would glide back to earth. The most difficult part was getting the balance right so that the center of gravity would be in the right place for the ascent, but then would shift just the right amount to facilitate unpowered flight. I carefully fabricated 1.7 bajillion parts and glued everything together; I tested its flight characteristics, as best I could, by tossing it around the room in various configurations.

Of course, the woods is no place to launch a flying torch, so I had to wait until the last day to send my creation on her maiden voyage. I had a location chosen--a field near my route home. It was on a farm, but unsown for the winter, thus presenting a vast expanse of non-flammable dirt where I could be fairly certain of recovering the glider.

The fly in the ointment was the breeze across that wide, flat expanse. With no terrain to dampen the wind, I had some stiff gusts as I walked out to the launch location. They weren't especially frequent, and I figured I had a pretty good chance of getting the rocket aloft; but as I prepared to hit the button, along came a gust and knocked the whole thing over. I brushed off the dirt, set it upright, and readied to push the button; again, a gust of wind toppled the thing. So I got smart. There was a utility shed not too far off, so I relocated to the leeward side of the shed. Now I could be certain the wind would not blow the launch pad over while I was trying to set it off. I readied, pressed the button, and waited...after a couple of seconds, I heard the familiar hiss as the engine ignited, and the bird took flight.

It got just to the elevation of the utility shed. Suddenly, clear of its windscreen, FOOM! The rocket was hit full force by the wind. It immediately made a 90 degree turn in the air...and of course you geometry nerds know that when a vehicle is traveling vertically and makes a 90 degree turn, it isn't going vertically any more.

The next few seconds all happened in slow motion. Traveling horizontally, the rocket's path was now curved downward by gravity. With plenty of fuel left to burn, she arced down toward mother earth, nosing gently into the ground and began plowing a new path through the fallow soil. Turns out the aerodynamic characteristics of such a vehicle are unsuitable for subsurface operations, and the body began to shed its 1.7 bajillion pieces in order to improve the vehicle's dirt-navigation capabilities. After what seemed like a month but was probably closer to five or six seconds, the propellant was exhausted and the rocket came to a stop.

Of course, those of you who have built and launched model rockets know that the engine was not yet spent. We had entered the delay phase, where the engine emits smoke without providing propulsion. The fuselage, stuck in the dirt at a disconcerting angle just a few yards from where it had been launched, spat a cloud of smoke for an interminable period as I braced myself for the coup de grace: the ejection charge. It had been designed to displace a lightweight nose in flight; but the nose was immovable, which meant the burst would displace the comparatively heavy fuselage instead. It did so, quite spectacularly.

The scene was like a miniature disaster area, like the aerial shots you see on the news of a plane crash: a swath of blackened earth terminating in twisted wreckage with wisps of smoke rising from unrecognizable chunks of debris. Delicately carved bits of wood were strewn randomly about--a part of a wing here, a tail fin there. It was quite the catastrophe, in miniature.

All in all, it was a pretty good vacation. But it could have ended better.

I was working for a small biomedical company outside of Philly. I had just taken over as the primary EDA draftsman as the previous one had retired. Just before he left we had converted from CadStarV to OrCAD for new designs. The two packages did planes completely differently, OrCAD doing a simple polygon flood fill, and CadStarV using plane layers. I had had a brief introduction to CadStarV, but most of my OTJ training was on OrCAD. I was tasked with relaying out an older design to convert from a 40pin DIP processor to a 44pin socketed PLCC in CadStarV (we didn't want to expend the time and money to convert the design files to the new platform). This particular board had 3 separate ground/power plane pairs (digital, analog, and patient connected). I successfully changed the footprint and re-routed the board, including changing the shape of the plane separation between analog and digital ground under the processor. But when exporting to gerber I forgot to follow the convoluted process to connect the 3 separate plane pairs to their nets. We got the photo plots back from the board house for review and no one spotted any problems, so we had a small run of boards manufactured. Then we had about 10 of them populated at the assembly house and sent them to the in-house test and calibrate department. One of the T&C techs came to me to try to figure out where he could tap into power for part of the board because he was having trouble powering it. I checked the design files and identified a pin to grab power from, and looked through the board (back-lighting the board with the sky out the window) and realized that there weren't any thermal reliefs connecting the plane to the pin. I checked a few more and didn't see any thermals connecting pins until I looked in the patient connected side. I then grabbed the photo plots again and to my dismay and horror discovered that the only section of the board that had any ground and power net connections to the planes was the patient connected section.

My only saving grace is one of the engineers had signed off on the photoplots, so I didn't have to take the brunt of the blame.

One of my most memorable fails was from grad school. We were adding a weather station to my adviser's PV array so we could compare weather data including solar irradiance to the electricity generated. This PV array uses micro-inverters instead a centralized inverter which means each panel has its own small inverter connected directly to AC. We chose to use self tapping screws and I managed to put a screw right through the the array's mounting rail and into the AC cable on the back side. The system was powered down while we were working but as soon as I flipped the AC disconnect, it looked like someone set off a firework under the PV array. The circuit breaker tripped immediately and I started panicking thinking I had damaged the new PV array. Turns out I shorted a phase to ground through the screw. No real lasting damage to any equipment but the undergrads working for me never let me live that down.

When following the Hater-matic guide I accidentally grabbed an ac power supply from my parts bin and fried the thermal printer

My biggest fail was designing a clock controller with an ATTinyx5 and a 32.768 kHz crystal and not adding any loading caps because I had misread the datasheet. And then having a batch of 300 of them manufactured. All of them were ~120 ppm fast. Fortunately, I was able to work-around it in firmware, but for a moment there I was faced with the prospect of sending a freshly manufactured batch of boards to the Albuquerque landfill to rot alongside the ET 2600 game.