×

SparkFun will be closed on Tuesday, December 24th, and Wednesday, December 25th, in observance of the Christmas holiday. Any orders qualifying for same day shipping placed after 2:00 p.m. (MST) on Monday, December 23rd, will be processed on Thursday, December 26th, when we return to regular business hours. Wishing you a safe and happy holiday from all of us at SparkFun!

Please note - we will not be available for Local Pick up orders from December 24th-December 27th. If you place an order for Local Pick-Up we will have those ready on Monday, December 30th.

Hello there everyone, and happy Friday! We are here, once again, to provide you with a smorgasbord of fresh new products! The Pixy2 CMUcam5 is here, we have a new soldering iron and tips from Weller, two new LilyPad boards, and an accessory cable for your RockBLOCK 9603. Let's jump in and take a closer look!

Now your can be even pickier about what you see!

The Pixy2 CMUcam5 is smaller, faster and more capable than the original Pixy. Like its predecessor, the Pixy2 can learn to detect objects that you teach it, just by pressing a button. Additionally, the Pixy2 has new algorithms that detect and track lines for use with line-following robots. With these new algorithms, you can detect intersections and “road signs” as well. The road signs can tell your robot what to do, such as turn left, turn right, slow down, etc. The best part is that the Pixy2 does all of this at 60 frames-per-second, so your robot can be fast, too!

Solder down the hatches!

The WE1010 from Weller is a powerful, 70 Watt soldering station perfect for passionate hobbyists, DIYers, and anyone who needs to build or repair electronics. This soldering station operates at 120V and features an easy-to-read LCD screen with three push buttons to provide variable temperature control, a front switch for easy power control, and intuitive navigation features. The included 70 Watt soldering iron is lightweight with an ergonomic foam grip and an interchangeable, iron-plated, copper ET series tip. The soldering iron can even be housed in a reinforced safety rest to provide you with extra stability and safety!

Since the WE1010 requires proprietary soldering tips from the ET Series, we are also carrying three to fit whatever soldering needs you may have. They come in screwdriver, single flat, and conical varieties!

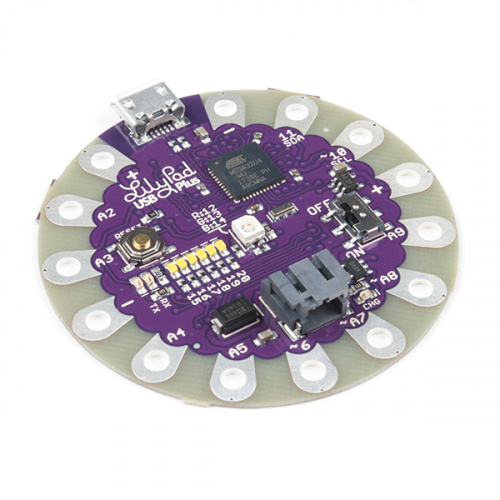

Using LilyPad for your e-textiles just adds up!

This is the LilyPad USB Plus, a sewable electronics microcontroller board controlled by an ATmega32U4 with the Arduino bootloader. It has a built-in power supply JST (and recharge circuit) and an on/off switch, and the only extra piece of hardware you need to program the LilyPad USB Plus is a micro-USB cable. We've also added an RGB LED in the center of the board, along with six white LEDs, to act as a bar graph. The LilyPad USB Plus was designed to streamline your next sewable project by keeping things simple and giving you more room to work, while eliminating the need to sew a power supply.

I can see the light!!

The LilyPad Light Sensor is a sewable breakout board with an ALS-PT19 light sensor built in and ready to use right away. Each sensor outputs voltage between 0V and 3.3V, depending on the level of ambient light shining on it. As more light is applied on the sensor, more current will flow from the board through the signal tab to the microcontroller you connect the sensor to. If the sensor receives no light, no current will flow through it. In a typical indoor lighting situation, the sensor will output around 1 to 2V. Adding this board into your next e-textile or wearable project will really open up the possibilities for light level sensing.

This is a simple accessory cable meant to be used in conjunction with the RockBLOCK 9603. The RockBLOCK 9603 Accessory Cable is terminated with a simple 10-pin, Molex-style connector at one end, and a male hookup pigtail at the other. This accessory cable will help speed up your development time, meaning you no longer need to terminate and crimp your own connector for the RockBLOCK 9603. If you're going to connect the RockBLOCK 9603 to anything other than your computer's USB port, you are going to need this cable. Once attached to your RockBLOCK, you will be able to incorporate it into a breadboard, development platform or anything else that you would normally attach a hookup wire to.

That's all for this week, folks! As always, we can't wait to see what you make with these products! Shoot us a tweet @sparkfun, or let us know on Instagram or Facebook. We’d love to see what projects you’ve made!

We'll be back next week with even more fantastic new products!

Glad to see the light sensor for LilyPad, even though I generally don't use LilyPads in my projects. (I've been using Arduino ProMinis.) I found early on in my "flashy" projects that it was best to include a llight sensor so the processor could adjust the brightness of the "NeoPixels" (such as these) to ambient light -- otherwise they can be blindingly bright indoors, especially at night.

BTW, I'll keep the LilyPad USB Plus in mind for future projects, as that built-in battery charger looks interesting.

Nice to see a Weller station in addition to the Hakko. I'm not familiar with this new station (my work-horse at home is a WESD-51), but I really dislike the Hakko interface. ... Wait... Did you drop the Hakko from your store? I wanted to compare the two items in your catalog and couldn't find the comparable Hakko.

Another reason why I tried to petition my local maker group to invest in the Wellers (until another member donated a Hakko that they won as a prize somewhere) is even though the Weller tips are "proprietary", they are also only $5 a pop. Hakko tips are $8 a pop and when risking tip burnout with people just learning to solder those $2 savings add up. (I want my two dollars!)

Meh... enough ranting. But I want one of those Geek hats that Angela used to demo the lilypad light sensor. Is there a tutorial available?

That hat is one of my favorite builds, there isn't a full tutorial, but you can see some detail photos in the light sensor hookup guide. If you'd like I can grab some of my illustrations/artwork for planning and add them to the tutorial for reference.

Oh, the Geek logo is felt. I didn't realize white felt makes such a good light diffuser, but that makes sense for synthetic felt (since it is essentially a mass of uncolored/clear plastic fibers/lightpipes). Only two LEDs? Did you use fabric glue or iron-on stabilizer to attach the red logo to the white backing? I'm guessing fabric glue to attach the full logo assembly to the hat to keep from ironing the LEDs... ;-)

Umm... yeah... Maybe a quick tutorial to go over some of the detail techniques would be good. ;-)

There are four LEDs, one under each letter. I used Heat'n Bond iron-on double sided adhesive, though you do have to be a bit careful with acrylic felt cause it can melt if you get the iron up too hot. I think I just used hot glue to attach the logo to the hat, it's held up over a few years now. I've got a few extra hats in my studio that I was going to use for a tutorial, maybe it's time to dig those out!

Here are two resources that aren't the exact project but go over some helpful techniques Insulation Techniques for E-Textiles and Planning a Wearable Electronics Project.

Thanks for posting the links! They're great resources!