SparkFun is moving forward after most have moved home

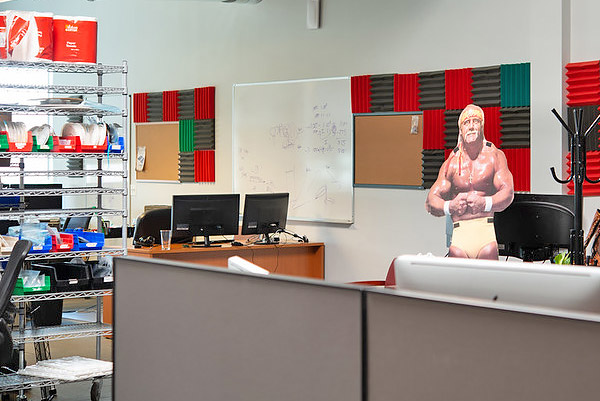

For around two weeks now, most of SparkFun's employees have been working from home. Our HQ mostly consists of vacant workbenches, quiet breakrooms and dark offices.

It's essential that we thank our shipping, receiving and production crews who are still going into our headquarters, albeit on staggered schedules and with hefty sanitation protocols, keeping the lifeblood pumping for this company. SparkFun's future would be on uncertain ground without their hard work during all this; we can't express our appreciation enough for their willingness to be there in person while the rest of us continue working remotely to keep the number of people in the building as low as possible.

This "new normal" is definitely taking its toll, but it needs to be said that we are very thankful to be working, when so many are not.As long as SparkFun is in operation, we will always strive to provide new and innovative products to our consumers. Much of that innovation comes straight from our fine engineering team. Last week, I asked our engineers and product service pros questions about what it's been like to work from home.

If you've taken a tour of SparkFun you know that we have no lack of essential tools (and toys) for those working directly on SparkFun's products. From oscilloscopes and hot air rework stations to microscopes and 3D printers, we've got it all. Without all of these tools at our engineering team's disposal, I was curious to see how they were getting along and what their home workspaces were like. Let's dive in.

Communication, as always, is key

One of the biggest things I kept hearing about was communication with team members. Let's face it, not everyone enjoys a video chat, and I'd assume our engineers probably aren't the biggest fans of having to do it as often as they are. Being able to turn around and ask a question to a coworker 10 feet from you certainly has its benefits.

Maybe the toughest part of not being near colleagues is that we all truly enjoy working together. One team member said it best:

“My favorite part about working at SparkFun is the people I work with. Being at home is difficult for me because I don't get to see everyone daily like I used to. Also getting answers to quick questions is a little more tough remotely."

Several others had similar responses. While working on a new sensor breakout board, one engineer said:

"The biggest struggle for me has been not being able to walk over to someone's desk to ask them a quick question. Instead I have to send an email, or in a video conference for a design review, I need to describe the area I would like for them to zoom in on or describe how something could be routed better, instead of just pointing to the area."

Tools of the trade

Aside from communication being a big part of what our engineering team needs the most, tools are every bit as important, and the separation from tools and equipment has been difficult for some. While I'm sure many of our engineers have a great workspace full of tools, I can imagine that they don't all have that perfect, super tiny screwdriver set that you need. When it comes to prototyping, a home workspace can't possibly match an in-house warehouse full of every wire, transistor or capacitor you might need, a fact that is not lost on Founder and Engineer Nate:

“It's hard not having access to the warehouse! It's so nice just to be able to grab that MOSFET or that connector when prototyping something."

Other than not having all the right tools at your disposal, the simple unfamiliarity of a different workspace can be a challenge. You know exactly where your 5mm hex key is on your pegboard at work, but without that same setup at home you'll probably find it after searching for 20 minutes through the boxes at your feet. A QA specialist summed it up:

"The lack of work space and limited resources are a challenge. My desk at work has more space, better lighting and bigger monitors. There are also work stations that have all the tools I could ever need to solder, rework, clean, inspect, power and stress test boards!"

Here are some of the top tools our team wishes they had at home, in their own words:

- "I wish I had a panavise and third hand kit in my workspace. Maybe it's time to buy one!"

- "I actually don't have a hot air gun at home because I don't do much SMD work here, and yet I always find myself in need of one at crucial moments."

- "The only tools I use at the office that I don't have in my home office/lab are a Dummy Load for testing power circuits and a thermal camera. But for the most part I have everything: an oscilloscope, function generator, power supplies, soldering iron, and even a microscope if I need to do any fine pitch soldering."

- "A good, very small, variable bench power supply."

- "A 6-axis CNC mill, drill press and table saw. Oh.... you mean for work? I'm pretty well set in that department!"

- "A better chair - I skimped on my desk chair buying a $20 desk chair and it's difficult to sit on for longer periods of time."

- "An Ethernet switch. I have two computers at my desk now (work and personal), but only one Ethernet cord that is long enough to route around the room rather than through it."

- "I still need to get my oscilloscope from work... I also need a cover and ventilator for my 3D printer, in addition to some sort of freestanding pegboard wall so I can organize all of my tools (which are currently just thrown into a large box)."

- "An oscilloscope."

Shop Essential Tools for Working from Home

The most important tools

Over half of people I asked said their computer was the most crucial tool at their disposal. With engineers currently working on GPS boards, Raspberry Pi HATs and "the mother of all data loggers," having a computer on hand for laying out hardware in EAGLE is pretty important. Several engineers mentioned re-purposing larger 4k televisions for their monitors to give more room for layout if they didn't already have multiple screens or ultra-wide monitors.

Aside from the computers, multimeters, soldering irons, digital logic analyzers and J-Links that were mentioned as crucial tools, there were a few that stood out from the others. One engineer shared his non-negotiable:

"The DAC for my headphones is essential. I can't get work done without good music."Plus, a handy tip from Nate:

"I've said it for years and I'll say it again: sticky tack. It's crucial for holding things in place to solder. Far better than a third hand."Maybe we ought be be carrying sticky tack in our storefront? ¯\_(ツ)_/¯

So that's how things are going for us at SparkFun in this current strange environment – it's not exactly easy and definitely not ideal, but we're more thankful than ever to keep working with people we like, at a company we care about, on excellent new products for our community. Thank you for your ongoing support - it means everything to SparkFun - and we'll get through this insanity together.

If you're working from home, how's it going?

Share your story with the community by snapping a picture of your home workspace using #myeeworkspace. Tag an interested friend and us (@sparkfun), and some of our favorite submissions just might have a promo code sent their way!

- What is your biggest struggle?

- What are your essential tools?

- Have any helpful tips for fellow engineers working at home?

- What are you currently working on?

Like many, SparkFun's engineers have been #workingfromhome. If you are too, what's your top struggle? Favorite tool? Current project? Tips for fellow engineers? Post a pic of your home workspace with #myeeworkspace, tag us & a friend! We may have some promo codes lying around... pic.twitter.com/2gYOAYzPyG

— SparkFun Electronics (@sparkfun) April 1, 2020