In the last several years, technology to support agriculture has advanced at a rapid pace and is only expected to continue growing. Given the unique, remote and often expansive nature of ag tech, the tools needed can vary greatly. Whether you are implementing a DIY solution for long-range communication and data collection, or leading a company building complete systems for environmental monitoring, the options can be overwhelming.

Precision Agriculture Tools from SparkFun

Over the years, many farms and ag tech companies have used SparkFun parts for building DIY systems or prototypes. We took a look at how those parts were being used and put together a page that provides uses cases and consolidates parts used in the following areas:

Explore Use Cases

“The biggest benefit this project has is that we can have secure data connections with open source sensors that already have Arduino libraries and drivers written. We knew the sensors we wanted to use, but as soon as you need to communicate over long distances in noisy environments things get complicated. The Qwiic Midpoint is going to solve a lot of that headache.” - Alex Jones, FarmHand Automation

“I may only have a couple minutes per day with each animal to perform a health assessment. Having some automated tools that are able to provide support throughout the day and automatically feed me data on the herd helps to ensure that I’m getting the bigger picture of herd health, and can act early on it.” - Cory Spencer, Haltwhistle Cheese

What tech have you found that works well for your ag tech needs? Let us know in the comments!

Hmm... sounds to me like some of these folks would also benefit from SparkFun's "A La Carte", as many of them might not have the time and/or skills to design & build their own boards. I know that I like and enjoy designing and building my own electronics, but I'm quite willing to have professional farmers produce my food (even though I enjoy hearing about what they do) -- they have skills in that which far outstrip my meager talents!

Thanks so much for this comment. You're right - ALC will be helpful as more people across industries start to experiment and prototype with different types of tech. And - yes - we are seeing many use cases where people who are experts in their field need tech to move their work along...they don't want to be EEs, so the breakout boards, documentation, and sample code available online have proven to be supportive.

I just made a presentation on this subject for FabAcademy recitation Agriculture part of “sustainability, materials, agriculture” on the 5th April 2021 by Luc Hanneuse and Florent Lemaire local instructors in AgriLab UniLaSalle . We were honoured to be invited by Neil Gershenfeld to present with Marcin Jakubowski of Open Source Ecology and Alysia Garmulewicz of Materiom . video link : https://vimeo.com/533524899#t=38m

... Sparkfun also came to the rescue when I needed a solution to precisely determine the ground speed of one our vineyard tractors at speeds below 5 mph. We needed a way to operate the machine slowly, but at very specific speeds as part of our precision fungus management program. We do not have expensive application rate controllers on our machines, so ensuring our grapevines are getting the appropriate dose of fungicide requires the tractor to move at a consistent speed. Now traditionally a tractor's speed is estimated from the reading on the tachometer, but since our tractor has a hydrostatic transmission, the engine speed is not a direct indication of ground speed. Simply mounting a speedometer was also not an option, since most traditional speedometers are not accurate at very low speeds, nor do they indicate in 10ths of miles per hour, which is what I needed.

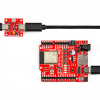

My solution was to build a speedometer based on GPS. Normally an un-corrected GPS will produce somewhat sporadic ground speed readings at very low speeds. But since the responsiveness of the readings is not as important as the precision in this application, I programmed the unit to keep a running average of the last 5 GPS indicated speeds, updated once per second. The result is a unit that reads in tenths of mph, down to under two mph. We normally use it between 3.5 and 10 mph.

The unit uses a Redboard Turbo and a GPS module with built-in ceramic antenna mounted in a Sparkfun red plastic project box. It is watertight for washdown and it has four disc magnets on its base, so using it is as simple as turning it on, setting it on the engine hood or any ferrous metal surface, and waiting for a GPS signal lock. It has a large blue sunlight readable 7 segment LED display which can read from about 1.5 to 99.99 mph.

I built a GPS tracker to control the water cannon and end guns on our 4.5 acre center-pivot irrigation machine. This allowed me to irrigate an additional acre along the irregularly shaped outer perimeter of one of our hay fields. Being able to track the location of the outer end of the machine allows me to program multiple start/stop positions for multiple end guns. This is far beyond what the old mechanical cam-microswitch system did, which only provided for one device to be controlled between two predetermined set points. The result is more crop production and better weed control and water conservation through reduced overspray. I used one of Sparkfun's GPS modules, a Redboard Turbo, two 4-channel relay shields, and a serial LCD display. The set points are field programmable and the system is mounted at the end of the machine in a raintight enclosure, similar to a lawn sprinkler control box.

I was wondering if anyone had done something like this!