After checking out a handful of factories on the geek tour in 2009, it was time for me to return to China to visit some of the factories that make goods for SparkFun. I've got far too many pictures and videos for one post so I'm going to break them up into three posts. This is the 2nd post - you can read Part 1 over here and Part 3 over here.

We've done an astronomical amount of business over email. We email a supplier, request 500pcs of something, wire the funds, and the goods show up 6 weeks later. Multiply by a couple years and we've sent thousands of dollars all over the world. We never talk on the phone, and I've never met the majority of folks who supply us with products like cables, LEDs, tools, etc. The purpose of the trip was to meet face to face with a small fraction of vendors located in China near Shenzhen.

Ok, that's a lie - half the trip was about meeting vendors, the other half was about geeking out and seeing how neat stuff is made.

On our 4th and 5th days, Louis and I toured a soldering iron factory, a clamshell factory, and a lithium polymer battery factory.

Located in Shenzhen, Atten makes the SparkFun soldering iron and we've been very impressed with the quality. Checking out Atten was great!

Testing massive amounts of soldering irons. Atten employs about 600 employees and can build about 150 irons per hour!

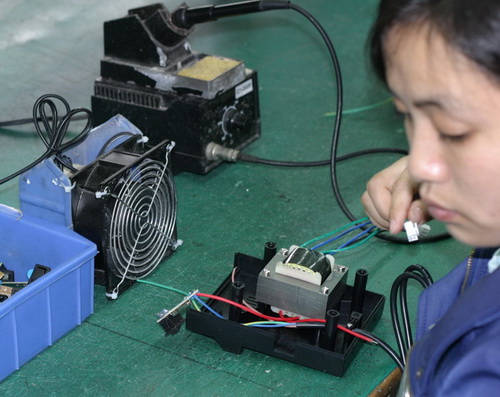

The assembly of the iron handle.

The soldering iron base is surprisingly simple with the bulk of the space being the transformer. Note the soldering iron in the background to assembly the iron in the foreground. There's a joke in there about who built the first soldering iron...

The infamous SparkFun soldering iron kit. Make sure to watch 5:21 to 6:40 - it's hilarious. I just need to put this soldering iron kit together so that I can then put together my soldering iron kit...

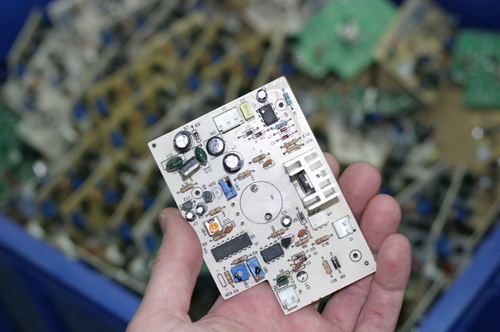

This was one of the control boards for an unknown model (probably not the one we carry). These PTH electronics are built very similarly to the other factories we visited. Lots of through hole components on a 1-sided board soldered with dip soldering (not Dual Inline Package, but actually dipping of a board into a solder pot).

I was pleased to see them using connectors instead of soldering directly to cables and boards. This allows for faster assembly and easier maintenance and repair of units.

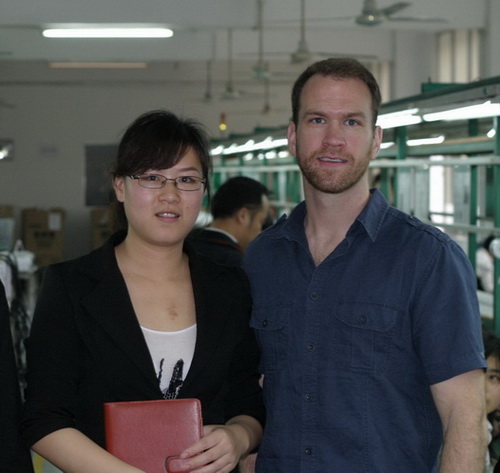

Myself and Iris, our tour guide.

Atten also builds hot-air rework units. Above you can see the assembly of the nozzle elements that the air passes through to heat up.

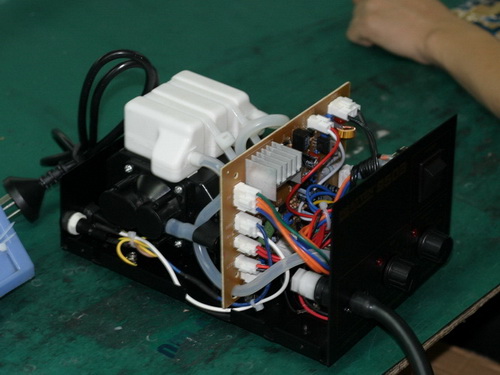

Check that out! It's the air pump as well as the control electronics for the heating element.

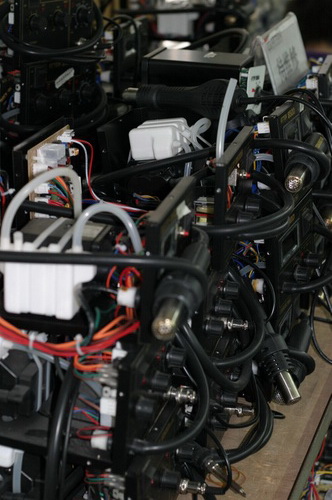

They build a lot of rework stations!

The test jig is very simple. They place the heat gun into the holder where the hot-air blows across the thermal probe (shown). The correct temp levels are checked and the unit is moved on.

A video from the floor of the Atten assembly floor. Very clean, very efficient, and well-run.

Our next stop was at the vacuum molded plastic facility. Vacuum plastic is also known as 'clamshells'. In the past 12 months SparkFun has started to 'retail package' some of our products utilizing this type of clamshell packaging.

Vacuum molded plastic is completely different from injection molded plastic (an example of an injection molded product is here). Because clamshells generally need less precision than injected plastic, the preliminary molds are made of plaster. Above a gentleman uses calipers and hand tools to create the structures that will end up as cavities when the plastic is pulled across it.

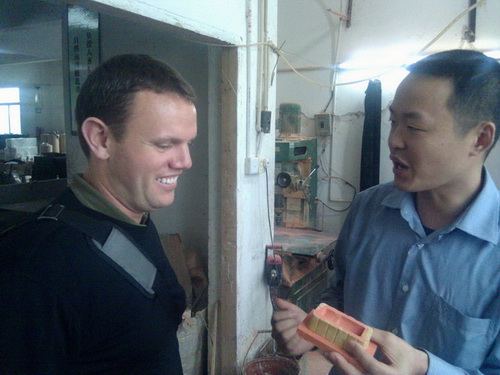

Louis and Ken discussing how molds are made.

For more precise clamshell parts, aluminum is CNC'd. CNC'ing takes longer than manipulating plaster, but is easier to create if the original design is modeled in CAD rather than rough drawings. Note the many circles built into this mold. This is a mold for SparkFun's upcoming retail kit for LilyPad.

A very cool shrine located on the production floor. Can anyone identify the deity or the writing?

This is another SparkFun clamshell mold - in copper! This is mold known to us as "1AR" and will hold larger items (hence the deeper wells. You can see even more of our molds in the background: the same LilyPad shell (shown above in aluminum) and one for our generic parts clamshells.

The process goes like this: the original master mold is made of plaster or aluminum. Then a negative is made from this master mold. Then multiple positive molds are made of the negative mold, in copper. Why copper? Because it stands up well to the vacuum mold process while being lower cost than aluminum, easy to cast (lower temperature than aluminum or other metals), easier to modify (copper is malleable), and easy to recycle.

At the top of the picture you can get a sense for the width of the raw plastic sheet. The copper molds are then 'panelized' into an array to reduce waste. Multiple copies of the same clamshell are then vacuum formed (created) at the same time.

Here's the vacuum forming machine in action. The machine pulls in a new piece of plastic from a continuous roll. The plastic is sucked against the array of hot molds - thus making a whole lot of copies of the same piece. The mold is then switched off and compressed air is used to cool the plastic down. The mold is then pulled away from the (now cooled) plastic. The process then repeats. Amazing stuff.

The final step of the clamshell process is 'depanelization' or cutting the sheet apart. Every design therefore has to have a custom blade created to match the outline of the clamshell. Above, you can see one such cutting tool. The blade is anchored to the wood. Black foam is implanted around the blade. When used, this cutter is aligned to the plastic sheet by hand and a large press comes down on the frame of the blade. The foam pushes back exposing the blade and cutting through the plastic. It may sound a bit wacky but this is a very common technique for cutting many things including vinyl and fabrics.

Myself, Ken, and Perry at the factory.

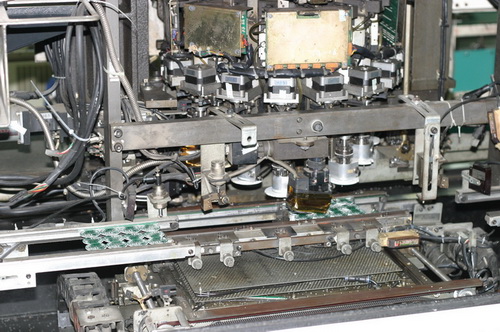

The following day Louis and I took a tour of a lithium polymer or LiPo battery making facility. The most important part of any LiPo pack is the safety circuit. All our packs come with a circuit that protects against short circuit, over voltage, and under voltage. We got to see two very impressive Gatling gun type pick and place machines.

I apologize for the loudness of the video, but it gives you a sense of just how massive and noisy these machines were. MANY components are slapped onto a panel then the panel is advanced out of the machine. Watch the video a couple times. This machine is probably 50 to 100 times faster than our current pick and place machine.

Once the safety circuits boards are populated they are tested.

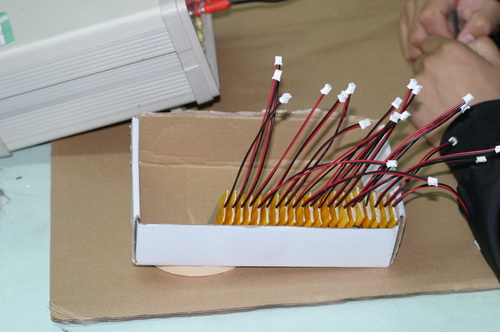

Here are the raw LiPo cells - ready for soldering.

The safety circuit is soldered on.

Wires are attached and the entire safety circuit is wrapped in high-temperature (kind of like Kapton) tape to electrically isolate the circuit.

What I didn't realize is that every single cell is tested. Above, you will see a large bank of clips that temporarily connect to the anode and cathode tabs on the bare LiPo cell. Every cell must be charged, then discharged, then charged again.

These are square cells. Every cell is monitored during these charge/discharge/charge cycles. If the cell is not taking enough charge, or the discharge curve is inadequate (internal resistance is too high or low), then the cell is recycled. Every cell! That's hundreds and thousands of cells tested every day! We test every single device we build at SparkFun but we hammer on test procedures until they are a few seconds long. These cells require multiple hours to test, therefore the factory dedicated entire floors to testing banks. It was a huge operation.

Here is Frank, the owner of the LiPo battery factory and myself.

Frank was nice enough to take us to the park and show us a local temple. If you think you know a language try interpreting poetry. On the base of this statue and throughout the park, Louis and Frank were reading Chinese and interpreting the characters and the meaning. It was pretty phenomenal just how complex Chinese can be, and how well Louis and Frank knew two languages. It was a great couple days!

can't wait for Part 3 - touring factories in USA.

Like SparkFun? :)

What do you need clamshells for? I've never liked them. Go through all that trouble of vacuum-forming a plastic case to a mold, and then it just gets thrown into a landfill as soon as it's purchased. Waste of time, energy, and land.

Couldn't you make one unit for display and put the rest in cardboard boxes?

Or use a clear plastic case that can be re-used for something else? Like a stronger clear clamshell that doubles as an enclosure for a circuit?

I do not think Sparkfun should be proud of "clamshell" packaging. It is very wasteful, and toxic. Yes, so are electronics, but lets not gild the lily, ok?

I was happy to see that Sparkfun was using simple cardboard shipping boxes. I think that it should continue that through its retail line.

I love this post! You were "happy" to see cardboard! Amazing. This sounds like the biology students who would walk into my physics classroom and chide me for throwing a Mountain Dew bottle in the trash instead of the recycling. "DO you know it takes 15,000 years for that to break down in a land fill?" I would ask why do you care? Its in a landfill! Whoosh. Right over their heads. The programming since pre-school runs very deep. Tell you what, I'll eat as much lead and tantalum as you can eat caffeine.

What? You should care because the amount of energy needed to create a new can from aluminum ore is over 50 times as much energy as from recycled aluminum. If you don't recycle because you have no regard for others, at least do it to save yourself money.

I do understand the need for the clamshells in retail, but regnirps, your logic is missing exactly that.

Mountain Dew bottle. Plastic thingy. Energy is what sets us free. Without it you get slavery. Always. I want it abundant and super cheap. Being able to take about 3 horse power out of any wall socket is fantastic. That should be the goal. Not somehow associating cutting back on energy use with "greening" (what we used to call efficiency where the worry was dissipating enough energy to keep your parts from cooking). We are going backwards. All the wind farms in Eastern Washington have been shut down due to the dams needing to run their turbines in addition to spill-ways to handle river flow. There is more power than the BPA system can handle. The lines to California have a current limit ("Green" lobbyists managed to prevent hydro from being listed as renewable so there are government mandated wind farms in view of the dams on the Columbia). If I had an aluminum can plant close enough to use that excess power would I be exempt from recycling propaganda?

Do some Chinese people nickname themselves with occidental names to sound more friendly to the occidentals? I mean, I have seen some cases, specially in tech support, where these people call themselves like occidentals, but based on their way to speak english, you notice they are Chinese.

I have nothing against that, if it works then they should go for it. I just want to know what's going on with that.

These young people should be in school instead of earning bits by mindlessly producing goods like these. Without education, a lifetime of low income and drudgery is almost guaranteed.

China is overflowing with good engineers. The schools way overproduced and you should see all the ARM based EE/CS text books! One reason things are inexpensive is that you can get very high quality design and layout work done at very low cost. The competition for design work is high. People were making these same complaints about Japan and Korea 40 and 50 years ago. Give it a chance.

Nice posting Nate. I have a brother who does some vacuum forming. He uses wood tools and the equipment heats the plastic with IR, then it gets sucked against the tool. I figure the low thermal mass and insulating properties of wood make it work. I wonder what the pros/cons are. I think he does a lot of Lexan and that might make a difference.

I gotta say something about all that "myself" stuff! No offense, but it sounds like a semi-literate starlet ambushed by a microphone :-) "Myself, Ken, and Perry at the factory." Hmmm. Me at the factory sounds kind of Tarzan. I (am) at the factory. (This is) me at the factory. Ken, Perry, and I went to the factory. Not sure. People don't use 'I' in some places as naturally as they did 50 years ago. They use "me" incorrectly a lot. But "myself"? Better for an action, like "I drove here myself" though it is ambiguous compared to "I drove here alone" or "I did the driving and brought two others". How about "I made it myself". Dang! "I made it". Bad as "we have got to..."

Anyway, heading over in June for nearly 2 weeks in Guangzhou and Shenzhen on a similar jaunt plus a look at freight consolidators. Any tips?

Myself is the correct way to note such an image. Much as people say "myself included."

Maybe for historical purposes it would be better to just use your name. You could wind up being knows as "Myself".

Reminds me. When I write to or respond to emails from China, if I am not careful and sign with "Regards" I get in trouble. If I say the more casual (or British/Australian, etc) "Cheers" and my name, I get letters back "Dear Cheers" and it sticks. Shipments come to "Cheers" at the company. Now when I visit, how do I avoid embarrassing them? Print some special business cards with my name as Cheers? It is close enough to the way someone in Guangdong is likely to try and say "Charles".

Were they... ethical about their employees?

Just when I thought I was supporting a great American company, you go and show us your labor camps in China. Thanks sparkfun, for bringing me down again.

Comments like this drive me nuts.

If you arent gonna support any companies that utilize globalization, you should probably move to a cabin in the woods. Everybody usually has parts made or assembled overseas. I see this complaint all the time, being applied to things like tools and automobiles, but the fact of the matter is its NOT the 50s anymore. America has let its manufacturing base atrophy, and countries like China have stepped into the gap. Add to that the fact that factory jobs are seen as lower employment by many Americans, and noone seems to want to step into factory positions even when theyre open. I also like your use of 'labor camps'. These look like very clean and efficient facilities staffed by mostly younger men and women, who all look well fed and healthy.

"American company...", "America has let its manufacturing..."

You know what... you are not the only americans here, you are U.S.A. I'm american too, but I'm not from U.S.A., I am from South America.

I wish you could stop aproppiating the word "american" just for yourselves

One final thought. If the Chinese followed the rules of the free market (not Adam Smith's, but the one you're more accustomed to - the US market), you would kiss your cheap products good-bye. Keep that in mind.

Good to see that you got Internet service to your cabin in the woods, mr crazy man! Now, I love my country, and I'm from Texas, so I also love my state, but I'm curious as to where your xenophobia comes from. I buy American where I can, and I'm close to a couple niche manufacturers here in te metroplex, and most of them are doing pretty well for themselves doing contract work. I don't see what the big deal is about sone work going to china, especially looking at it from a business perspective, where margin is concerned.

And thank you, I do like my Arduino, but I originally started learning in highschool using nothing but discrete logic gates before moving to PLDs.

As for your P.S. and P.S. 2. (PPS?), there is no 'k' in America, and I looked through my posts and didnt see a spot where I misspelled or misused the word 'theyre'.

Im stil not budging on the Xenophobia thing. This isnt due to any garbage in my head, its what youve displayed is in yours. As far as making fun of my spelling by intentionally misspelling something that I never actually misspelled...uh, congrats? I hear Charlie Sheen is looking for a new opening act, you might want to send him your stats!

Also: still not following on the 'theyre' thing, but its whatevs man.

Sigh...

Sparkfun is still an American company. They are based in Boulder, Colorado. They design and put together many of their own things.

How is that not an American company?

And, there is almost no such thing as a truly American company anymore - parts even, come from all over the world. Remember that news article a few weeks ago about the globalization of sparkfun? it's not just China. This is the way the world works - deal with it.

You too are stupid. I never said that SF must not buy from China. And give me a break with your Kumbaya-One-Happy-Globalized world b.s..

Also, my main peeve was over the Chinese sugar coated reality painted by SF. Please, stop showing me happy Chinese CEO/supervisor faces. It might fly with moronic kids who buy from you, but not with people who know what happens in those places.

@ admin

Please cancel my SF account.

Uhm, Okay, but the "Kumbaya-One-Happy-Globalized world" is not what I was going for. It's not always going to be perfect but sure, globalization is the next step. it's already started, and is going to keep going, with or without holdouts like you. It's like how, ages ago, each town had it's own trading system. then towns started trading each other, then states, then nation trading within themselves, and now the last step is all over the world.

and also, there is no slave driver in china. the people there are actually happy - there is no sugar-coating. the only thing I wonder about is if he is actually named Frank. Chinese tour guides, at the very least, pretend to have american names for their customers. at least so they're easier to pronounce.

semi-pro wants them back on the farm. Maybe a good Cultural Revolution and a few 10 Year Plans will starve them back to his liking!

This is why I'm hesitant to buy from Spark Fun. All their products originate from china. If I can I would rather pay a premium for an American made product or even one made in Europe than to buy one that was made in China. If I have the choice I always buy American or Europe than to buy something made in China.

When I hear and work with China they always cause me grief and are just kinda shady business people. They also don't respect humans and the environment as much as I do. If it's easier to mass relocate people to install a dam or just force a person to shut up than to deal with the larger problem they will. Even if that person has been recognized by the Norwegian Nobel Committee.

By far and large they also don't respect our companies. They'll steal designs, make knock offs, and lock out companies (google).

Dealing with China is going to bite us in the end. It's just a matter of time.

When dealing with China "All Men Are Created Equal" has a dollar value attached to it.

This is not an issue of supporting Sparkfun, for the market will eventually take care of their success or failure.

It's just that... fine, they get their cheap stuff on other people's backs (home and abroad), but then they show us how nice and spectacular Chinese realities are. Keep your mouth shut as long as you catter to people other than "dumb" enthusiastic 20-something yr old hobbyists/college kids.

One more post like this and SF will end up on my s..it list.

You are not irreplaceable.

Then buy your products elsewhere instead of trolling the forums with your narrow-minded view of the world. I actually like the fact that they're making the effort to expose their supply chain to everyone who buys from them (hope I used they're and their to your liking!). Nate did say there were three posts, so there will be one more coming...time for you to pack it up and replace them with some other hobbyist supplier...oh...no wait...you're still here aren't you?

wow Semi,

First, let me suggest that most people are a complex hybrid of many views; people of every country are nationalistic-in-part, and internationally cooperative-in-part. I submit that morality does not lie in nationalism, nor in international trade - but perhaps it can be found in the deeper minutia of both activities? I bought a hat knitted by rescued sex-slaves in Nepal - Am I promoting the loss of textile jobs or promoting the protection of women? Sparkfun makes and exports products world-wide; it also shops world-wide on my behalf.

Did you know that the textile industry in the US was ripped-off from England? some engineers copied the mechanisms and built an industry in the us. Such machines included paper punch cards for programming patterns - which ultimately leads to the computer and Silicon Valley. At some point, good ideas have sex and multiply. This is a post of how engineers in the US and China share ideas, and I benefit.

If money is the only factor, there's no reason to have a business in Colorado instead of China. China is where everything is. You could be bigger than hobbyking, in China.

Watching the factories & the names come & go over the last years of Shenzen posts shows how fleeting the business is. They're not permanent organizations. These places set up a bunch of chairs & tables in a highrise floor, to make 1 product & then they're gone. The new economy is as just-in-time & modular as it gets.

Not sure why, but the site buried my comment in a random place out of order? >_< Hopefully you can answer it!

I get the same thing often, I guess it is because of the time difference (just a guess) I'm roughly 12 hours ahead of colarado so my comment, even if it is the first would seem older than the next comment of someone that is further back in time...

Hi Nate,

I'm always curious about companies that use suppliers/manufacturers based in China to create their products. I'm not saying this would happen with more than a few shady companies, but are you concerned at all about anyone (once they have your designs and know how to make them) taking your original work and making knock-offs? It happens with so many goods, and I know IP laws are rarely enforced there. If I had my own business (like SFE) it would be a huge concern for me. Have you had any issues/concerns with this stuff at all?

You do realize that copying a circuit is perfectly legal, right? You can't copy a circuit board design exactly, since that can be considered a copyrighted graphic design, but there's nothing stopping you from reverse-engineering it and building the exact same circuit on your own PCB layout.

You have to patent a circuit if you want to prevent others from re-using it.

Those soldering irons you see being manufactured and sold by SparkFun are already a Chinese knock-off of the Hakko 936. :) SparkFun even points out in the product description. If they can make the same thing cheaper and more efficiently, why not?

Exonerd,

Sparkfun makes a lot of OpenSource stuff, also, it OpenSources a lot of the stuff it makes (overlapping venn). Some people who live in China do likewise and were featured in the first post (Seeed).

What you are describing in the central angst of Open Source, and the lesser angst of out-sourcing (ultimately, unless the founder/ceo personally makes the product (as is essentially the case with coca-cola), the act of making and selling largely releases the design into the wild.

The barrior to copying is largely timing. As I have bought an Arduino ..., I can now load up my pick and place - oh wait, it's already last year's model.

all nice...you really need to update some of your tutes

We got the message, Spark Fun! We should all go work in China.

Spark Fun, don't you think it would have been more appropriate to show some startup manufactures here in the States? This kinda reminds me of that idiotic "Outsourced" flick on NBC.

Anyway, at least you can be happy that you took some pictures of a few Chinese spooks. You do realize that all those companies belong to the state, don't you?

"Here is Frank, the owner of the LiPo battery factory and myself."

You sold yourself to an Asian guy named Frank? ;)

Also... no tour of GoldPhoeinx? I really want to know if they are a good responsible place to order from!

I wanted to take a tour of Gold Phoenix but they are another 5 hours away from Shenzhen by bullet train. It would take 2 days of the trip for a 2 hour meeting. I couldn't justify it but will make it there someday!

Never mind Gold Pheonix - it's a bullet train - how totally cool is that?

Let me know when you hit HK. I owe you few pints :)

Oooh, okay, makes sense!

Thanks for responding to my pestering! Luckily it looks like the places you did get a chance to see seem like alright places for the workers.

I hear so many horror stories about China and its hard to wonder if any of it is okay.

Thanks for the tours and I also hope you get to GoldPhoenix some day! :)

-Taylor

Kewl, they use the same method to keep the soldering fumes out of their faces as I used back when I made circuit boards. A computer cooling fan. lol.

the deity is Guan Yu,or Guan Gong..

Awesome stuff. I'm guessing that copper is used for the molds because it heats up and cools down quickly. Also, copper is more expensive than aluminum not the other way around, I believe.

Correct. At current commodity prices, copper is about 2.68 times as expensive as aluminum per unit of mass and about 8.85 times as expensive per unit of volume. It must be used for some particularly useful property. As you said, it is probably because it heats and cools more rapidly than aluminum.

Ahh! I didn't think of thermal properties. Good point.

There is also an interesting property for copper: it can be plated easily (electroplating).

Just put a conductive varnish on your positive mold, put it into an electroplating bath (copper sulfate). Some time and current, and voila, a nice negative mold.

I don't read Chinese, but the shrine might be for Fudo Myo (or the Chinese name equivalent)?

I read Chinese. This is traditional Chinese. Meant to be read from the top down, the one on the right comes first. It generally means very good business (right) and lots of profits (left).

I'm pretty sure it's http://en.wikipedia.org/wiki/Guan_Yu. Notice the red face and the blade.

Ah, this is one of the characters from the great movie epic "Red Cliff". Thanks for the info.

Also known as Guan Di

Guan Di is his name....

http://youtu.be/Vwi77qlEl9c

Oooor, maybe it's the employee of the month. Sure beats the plaques they give around here.

(absolutely no offense intended, I poke harmless fun at my own religion twice as much)

Awesome, Nate. Just awesome. The pictures from the LiPoly plant, in particular, are amazing. Also, how does that solder pot dipping method work?

It's a simpler version of this.

Great stuff. Thanks for posting.

Neat. I deal with (and retrofit) several thermoformers like you saw over in China regularly here in Wisconsin. I have a trunk full of rejected mini-boxes for Littelfuse consumer packaging from when they were lining up the dies one time. Great for sorting and they lock closed and stack. It's amazing what you can get for packaging. Most of it is PET, but PLA (corn based biodegradeable clear plastic) has a slight corn smell before it's heated. Somewhat more brittle though.

My last intern was in a toy company in Hong Kong, I visited one of our China factory and everything is tested and tested again before getting in the final packaging. It's so amazing to see the entire manufacturing process in person. It was also not that clean, not like "electronics" factory where everything is shinny clean. It's a big old warehouse with tables in the middle and lots of people around them. I remember this room where all the tables where arcing towards the ground... The workers where not allowed to talk during work hours. They lived and eat on site. They had this big cafeteria where they had 30 min lunch. I also did not wanted to see the bathroom, just a glance was enough!! After my intern, I realize that I am lucky to live in North-America and getting a good education!

At one of the factories I visited, the workers were loudly talking and listening to dance music while testing products, until I walked in with their boss, and they suddenly turned it down and got real quiet. :D

Very cool. I love seeing where all these parts come from and how they're made. And I have no idea who that deity is.

I also like the who made who Soldering iron conundrum.