If you're anything like me, and haven't come out from the workshop in a while, you might want to take note. There is less than a week until Christmas. I know, I was shocked too. I mean are you kidding? This year just flew past. In the past year, SparkFun has attended numerous MakerFaires throughout the country. We spoke at conventions and held talks all over the world discussing open source electronics. We taught at schools and even managed to visit some hackerspaces along the way. At all of these events, we've had the pleasure to meet a lot of wonderful people that keep coming back to read our blog and check out the endless supply of widgets that our Willy Wonka-esque factory pushes out. Without you guys we couldn't be here. Thank you!

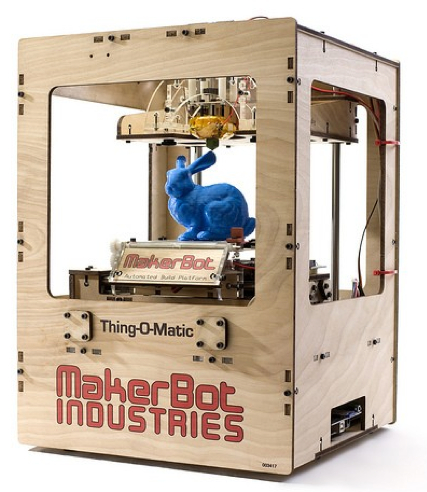

Due to all this wonderful support, we have also been fortunate enough to get some of our large scale tools up and running this year. We have added a vertical mill, a laser cutter, a pile of parts that may some day grow up to be a Rep Rap, and most recently we added a MakerBot Thing-O-Matic 3D Printer to our ranks of tools! Like I said, a lot has happened here at SparkFun this year. And now it's almost over. It's time to head to the stores, and brave the crazy last-minute Christmas shoppers. Yikes!

With that said, likely you, or someone on your shopping list is a maker, a creator, or an artist. You might be asking yourself "What can I get for them this year?" Maybe they have the latest Arduino. Or perhaps you went one step further and got them the SparkFun Inventor's Kit. Maybe they have a workbench that was just furnished with a fancy new tool kit. Or they just finished the last of the DIY electronics kits from SparkFun. What if I told you about the gift that keeps on giving? I'm talking about a 3D printer. These things can print happiness! Well, that might be an exaggeration. But they can print just about anything else.

The guys over at Maker Bot have created an impressive product. The Thing-O-Matic is a fully automated ABS extrusion based 3D printer. The printer comes in a kit form so there is plenty of fun to be had during Christmas break putting together this present. The skill level required to build the Thing-O-Matic ranks in the intermediate range. It's nothing you can't handle. The team over at Makerbot have worked up a great set of directions online to get you going. And the kit includes everything you need to build and begin printing.

Once your bot is built, there is a site called Thingiverse where you can download and share all the 3D models you could ever want. You can even learn how to make your own models and start printing custom designs!

I had the pleasure of building and calibrating our MakerBot. It was a blast putting this thing together. Like many people before me have done, I took a little extra time in the build process to work on customizing the casing of our MakerBot. Being an electronics company, what better to decorate it with than circuits right? I etched a SparkFun flame and circuit traces into the front and back of our case.

Once embellishment was done, it was time to get down to actually putting this thing together. Your new ThingOMatic will show up in one box filled with many smaller boxes containing many small parts and pieces. I won't lie, it was a little overwhelming at first. Take your time. Familiarize yourself with what you have in front of you. Settle into the boxes and make sure you have everything. Then begin your build. You'll thank yourself later for the extra time spent early on planning and organizing.

It took about 4 days for me to physically assemble the device. That was while at work doing Tech Support duties and building the printer on the side. I would say 6-10 hours is a fair guess on time it took. Once you have your ThingOMatic built, it's time to download ReplicatorG. This is the software you are going to use for calibration and printing. Once calibrated, you should give the calibration cube a print to test the system. If everything prints correctly, congrats! There are other example files you can print directly from ReplicatorG or you can head over to Thingiverse and pick something fun out. If something happens to not work right, Makerbot has a top-notch tech team (thanks Ethan!) who can help you out when you get stuck.vThere are also forums and build groups that can help out.

Makerbot is clearly doing something right. They have put together a nice product. They provide high quality support to their customers. They are working to build a community of makers who share and create together. If you are looking for something new and exciting - something that creative makers on your Christmas list will love - check out Makerbot Industries.

I bought one for my daughters and I for Christmas. Unfortunately, my wife thinks we need to wait till Christmas to start assembling it. So we will. I'm excited and my daughters will be when they find out.

Will you adopt me?!

I've got one of these and it is a game changer. It isn't exceedingly accurate. I use it for things that don't need accuracy better than +/- 0.020". Also, it doesn't handle overhangs at all except for small distances. This is because it doesn't have a separate support material. So, if you want overhangs you need to design in supports then cut them off after the build. Besides these limitations it works wonders. I am a mechanical engineer and it actually is pretty solid considering the cost.

A few suggestions for you SFE: I replaced put a 4" wide copper plate over the Heated Build Platform (using your heatsink glue in between), then over the top of the copper I bought some 5" wide Kapton tape that I lay down. When you clean the kapton with acetone the ABS sticks really well and makes for a smooth and solid foundation for everything you build that is easily repaired (the kapton tape).

+/- .020? Ok. That's about what I would have assumed. This is the kind of info I need to really justify buying one of these. Also, where did you obtain 5" wide Kapton tape? I can only find smaller widths with a quick internet search.

MakerBot Store carries 120mm wide Kapton tape. Link

Thank you for the link. I think Makerbot will be receiving an order from me after the christmas crazyness ends.

I own a makerbot cupcake (the version before the thing-o-matic) and after a few tweaks am very happy with it. It's something that any visitor of sparkfun would love. I've made a lot of things with it that have saved me quite a bit of money, in addition to launching a new company that would never have materialized if I hadn't been able to tweak part of the design and print it at home in ABS.

I've built custom pogobeds with it and recently built a PCB Soldering jig (http://www.thingiverse.com/thing:13914) that saved me several hours while soldering many, many boards.

If you have the money, get one and you won't regret it!

Very cool. Nice work. Way to simplify a repetitive task like soldering 10 boards. Very clever!

I bought a Makerbot in March and I'm very happy with it. It's a lot of fun to design something and have it printed out of ABS plastic right before your eyes!

I created a mount for a GoPro video camera that allows me to attach the GoPro to my scuba diving mask. Now I can get first person video of all my scuba diving adventures!

My Thingiverse.com profile is located here: http://www.thingiverse.com/3dprinterbot

I'd highly recommend getting a Makerbot!

Awesome idea. That's a really cool project to use the Makerbot for! Keep it up, and be safe down there.

Thanks! My wife loves to dive as well so she keeps an eye on me and makes sure I stay safe :)

On another note that might be of interest to other SparkFunners, I also designed and printed out parts for a quad rotor helicopter using my Makerbot. I haven't posted it to Thingiverse yet but other people have posted their quad on there.

I backed this one, http://www.kickstarter.com/projects/printrbot/printrbot-your-first-3d-printer?ref=NewsNov2311&utm_campaign=Nov23&utm_medium=email&utm_source=newsletter for the PrintrBot+

Wow. 830K pledged. Just wow. He basically got nearly 1400 preorders for a 500 dollar printer.

Hmm. two words of advice for this guy: Tax Lawyer.

Me too! Can't wait to get it. The 3D printing industry right now reminds me of the late '70s with the hobbyist market for microcomputer systems. 8080, Z80, Altair, TRS-80, Commodore, Apple and so on. Then the bigger players started showing up like IBM. HP sells a small 3D printer, but only in Europe and the web site doesn't list prices so you have to ask.

awesome machine but i think it should be made out of a steel alloy or something. but great machine great buy fast shipping spark fun is great.

Can a 3D printer print out a custom enclosure with cutouts for GLCD's? Norm

Yep, they can! There are a bunch of people that have created their own custom enclosures on thingiverse.com.

I want one of these so bad... ;_; but nobody will give me $1250... WAA

Man, I've been looking into getting one of these(dreaming, really) recently. One thing I'm concerned about is that 1 lb. of plastic sounds like it would go quickly. How long do the ABS spools seem to last?

Another awesome example of this, my own prints: http://hackaday.com/2011/08/29/eastons-animatronic-hand-gets-3d-printed-upgrade/ http://www.makerbot.com/blog/2011/09/01/3d-printed-animatronic-hand/ http://blog.ponoko.com/2011/09/01/3d-printed-upgrade-for-animatronic-hand/

Printbot should also awesome

I just finished assembling mine 5 minutes ago and about to make my first print! This thing is awesome and a pleasure to build.

Once you get it up and running, check out the Hollow Calibration Pyramid I designed: http://www.thingiverse.com/thing:8757

If your Thing-O-Matic is calibrated properly, you should get a nice, clean print!

Good luck!

Brett Jones,

Now, that's what I'm talking about! That's the kind of useful, problem solving thing I wish would be showcased instead of things like whistles and whatnot.

I think you just pushed me over the edge towards getting one of these things.

I've been threatening to get one of these. I think later this year I'm gunna do it.

It still weirds me out that it's made of wood, though. Wood isn't really known for it's structural rigidity and stability. I guess I'll just have to get over that.

Actually, the lack of rigidity is a feature. They're not made to especially tight tolerances and the frame needs to flex a bit in operation.

Wood not stable? Wow. It's not wood that unstable, it's how it's used in construction. you can always use wood glue, you'd never have to worry about it comming apart.

Don't let the wood frame scare you off. It's actually pretty solid and it works very well! It's rigid enough to get the job done.