Copper tape has countless applications in electronics from creating low-profile traces for electrical components to RF-shielding and antenna-making. Copper tape is even used to join things together using solder, like the stained glass on Tiffany lamps.

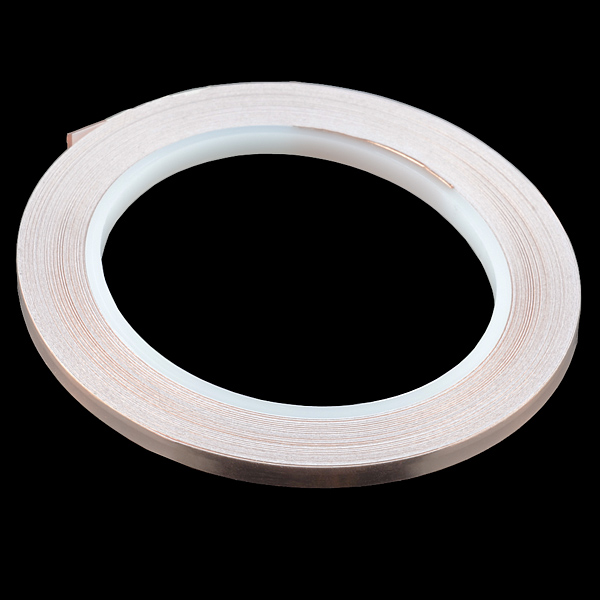

This copper tape is adhesive-backed, 5mm wide and comes in rolls of 50 feet.

Thickness: 3 mil

Copper Tape - 5mm (50ft) Product Help and Resources

LED Butterfly Pop Up Card

August 19, 2015

Craft an illuminated butterfly pop up card with copper tape, two LEDs, and a battery.

Let It Glow Holiday Cards

November 20, 2014

Craft a glowing card for friends and family this holiday season with paper circuits - no soldering required!

Light-Up Valentine Cards

January 27, 2015

Light up your love with paper circuits - no soldering required!

LED Robot Pop Up Card

August 19, 2015

Craft a paper circuit pop up card with a cycling RGB LED, battery, and copper tape.

The Great Big Guide to Paper Circuits

May 22, 2015

Let's take a look at different materials we can use to combine paper crafting and electronics.

Origami Paper Circuits

May 26, 2015

A quick tutorial to get you started in the world of light up origami flowers.

Paper Circuit Pin

April 11, 2016

This quick craft project shows you how to create a circuit using copper tape instead of wire to light up an LED and make a wearable piece of e-craft art.

Craft a Holiday Greeting with Love to Code

March 23, 2018

Craft your own paper circuit holiday greeting using the LEDs, a Chibi Chip, Love to Code!

Raw Copper Warning

This raw copper is not coated and can build up a layer of verdigris over time unless it is sealed.

Paper Circuit Traces

The 5mm copper tape is a great option for making paper circuit traces. It's a better option compared to using the 2" copper tape. Here's an example from the Light Up Valentine Cards tutorial:

Note on adhesive

The adhesive on this copper tape is not conductive. We carry this product in a version that does have conductive adhesive. For that, check out PRT-13827.

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

5 out of 5

Based on 4 ratings:

1 of 1 found this helpful:

It works great and is easy to use.

I like that it has the adhesive on one side, what a pain to try to glue down if it didn't. Using it was easy and made the project go together much faster. I will be doing cards with middle school students and this will make building the cards so much easier.

Great tape

Good for heat transfer from chips, good for running power and soldering to (a little tricky to solder on to, as there's adhesive on one side, but once you wet it, no problems). Also great for isolating rf noise in bare cables, a bit of this stuff, and an unshielded wire gets shielded great, especially when soldered to a ground plane. It's a specialty item, but sometimes it's really useful

This would make an awesome PCB trace fix!

dfsfdsfs

does it stays on fabric as well? is adhesive strong enough or is it more meant for glass and paper? thanks !

I just got the tape and I tried soldering to it and it doesn't work. I tried putting it in between and LED and a battery and it doesn't work either. Am I doing something wrong? My tape doesn't have a peel away back either. Also is it supposed to be somewhat transparent?

Hi, If you have not already contacted us directly, please contact techsupport @ sparkfun.com It sounds like you were accidentally shipped a roll of a different product. We'll be happy to straighten that out for you.

I`m excited to discover this site.

Could you also stock the 1 cm wide copper tape?

Patina-- Has anyone tried chemically "patina"ing this copper/ That is treating with metallic salts to give interesting colors? Is the copper covered with some protective coating?

I can confirm that this is the same stuff you would apply to the edge of pieces of stained glass to solder them together ( Used instead of lead came ).

Has anyone soldered to this? I just wonder if there is some sort of coating to keep the copper from tarnishing as I need it for capacitive touch. I did read that some copper tapes come with conductive acrylic adhesive but it seems up in the air on this stuff so I will probably will be soldering to it.

It's late for me to reply, but you can get gloss acrylic sprays to apply to this.

Can you use an exato-knife to cut the copper when it's applied to a board (to shape it)?

I have I made a some what help-full breakout board for one of the weird shaped 15watt op amp circuts (sold here)

This will be great to prototype capacitive touch sensors

This makes me happy. I LOVE THIS STUFF. I bought some from another "Amazin" site last year, and paid roughly $.12 per foot for 150'. If I run out, I know where to go now for 50% less. Every penny counts these days...

I agree w/ Mr. NPoole. Solid connection and thin but good adhesive. This stuff is nice and sticky, and it's worth mentioning that you can lift and reapply it without leaving a residue. I use my wire snips to cut off a section. I'm not sure what the max temp is, mine came in a zipper storage bag with no data sheet.

Yeah, I just recently bought some 1/4" x 36 yard from the A-site, but this SF version looks like the better deal if you don't mind it being slightly thinner (5mm ~ 1/5").

What temperature can the adhesive handle?

Another fantastic question to which I have only part of an answer. There's no rating to be found, however, I was playing with this tape and it appears that it can get quite hot for extended periods of time before coming completely loose (like... clothes iron hot), but at those temperatures it is more likely to slide around and/or peel... and of course after it cools it becomes quite stuck again. Final Summation: soldering to it doesn't get it hot enough to really mess up the adhesive unless you just hold the iron on it, I wouldn't use it in a really high temperature environment and expect it to remain adhered though.

Is the adhesive conductive?

How thick is the tape?

It seems to be. That is, when I overlap two strips of it and ohm it out, there is a solid connection between the two. However, I can't find any documentation to support that and it's unclear whether that's a function of the adhesive being conductive, or just being thin and allowing the copper foil to touch in places (although, the adhesive can't be too thin because it REALLY sticks). In short: I can't say for sure, but it does appear that sticking a piece of it to a conductive surface DOES create an electrical connection with that surface. For good measure I usually put a little dab of solder at the connections, though. (Being copper it really likes solder)

Thickness... Digital Caliper gives me .08mm without the paper backing.

Perhaps The adhesive could be peeled off in a small area and the copper indented downwards to provide a contact.

I tested this stuff myself it is not conductive. (the adhesive)

I tried to test this and got different results then Poole. I found it was NOT conductive, unless you let the edges touch or scrape off some adhesive with a knife.

If anyone is looking for copper foil tape with conductive adhesive, you can find it here.