Silicon Nitride Igniter - 12V

Everyone likes a (carefully controlled) fire! We've met some very ambitious pyros on our mission of enabling makers to keep making and they all have one thing in common: whether they're building a giant propane puffer or an autonomous potato gun, they all need to light something. Well, this is the right tool for that job.

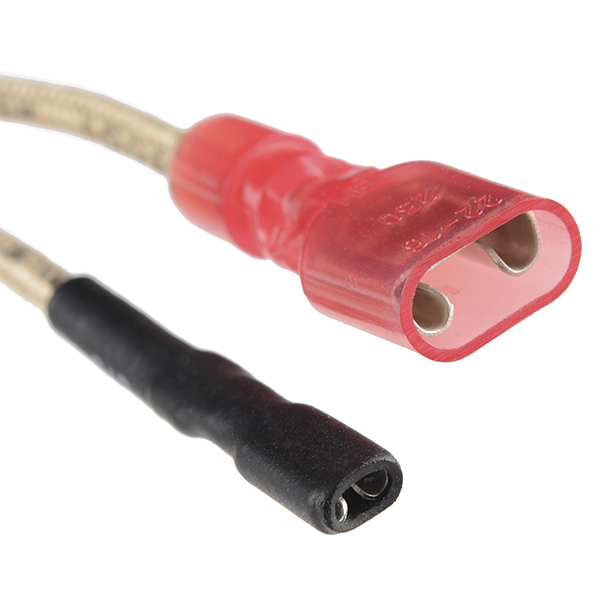

These silicon nitride surface igniters are used to light natural gas furnaces. Simply apply 12V and they quickly heat up to above 1300°C (that's white hot!) The heating element is cemented into a ceramic insulator and connected to a stainless steel mounting tab. This probably goes without saying but... be careful.

Note: Due to this item possessing a higher level of restriction we are unable to ship it outside of the United States. Sorry, world! If you have additional questions, please contact Customer Service. This item is only available for a limited time, order while you can!

- Operating Voltage: 12Vdc

- Max Temp: 1280 - 1400°C

- Current Consumption: 1.75-2.4A

- Cold Resistance: 1 - 1.4 Ohms

Silicon Nitride Igniter - 12V Product Help and Resources

ESP8266 Powered Propane Poofer

March 15, 2016

Learn how Nick Poole built a WiFi controlled fire-cannon using the ESP8266 Thing Dev Board!

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4.5 out of 5

Based on 2 ratings:

Works Perfectly

This is a must have if you are attempting to ignite propane for any sort of gaseous or liquid fuels.

Worked awesome!

Used it on my triflame sword on Discovery Channels Daily Planet! Super reliable ignition. I've used several different ignition systems for pyrotechnics over the years this thing is king!

Super cool! https://www.youtube.com/watch?v=tfAiAe7EGmM

-------------------- Tech Support Tips/Troubleshooting/Common Issues --------------------

Demo Video and Tutorial

This part was used in the Internet Controlled Flamethrower => [ https://www.youtube.com/watch?v=AI_m0yrUAlA and https://learn.sparkfun.com/tutorials/esp8266-powered-propane-poofer ]

Darn... Thermite ignites at something like 2,200C.

There goes my self-destructing self-destruct button project.

No, just use some magnesium powder as a step up fuse. It'll ignite for less than 1200C and burn hotter than 2200C. 12V ingiter --> Magnesium (strip or powder) --> Thermite (--> House?!)

Have fun!

Thats funny, My neighbor when growing up designed some of the first silicon nitride mini ignitors for Norton Company.

Funny how it wraps around and gets you later in life! .... Here's his patent for laughs: http://www.google.com/patents/US5085804

Yey, my exhaust flame thrower comes closer with that thing :-D

Finally! My plans to make my own soldering iron will come to fruition!

Well, I guess it 's about time I threw together that fully reusable, shoulder mount model rocket launcher I planned many years ago... :)

Since copper melts about 1085 degrees C, and another comment already indicated this unit is built for continuous heating, would it be possible to use this as the heating element with a thin solid copper filament to do 3D printing in solid copper. I have no hands on experience with 3D printers, only what i have read, so I am not sure, but it seams possible. Any thoughts?

Please bring this guy back! Mine are so useful, but I only have 2 and I'm a pyrotechnician. My fire swords and palm flamethrowers need more.

Ask and ye shall receive. Get some while you can though we won't have them once our current stock is gone. :)

Please bring this thing back it works so well and I only have 2! I have so much more pyromancery to do and I need this silicone nitride sorcery of yours to do it!

Tried to use this to hard solder some stuff, not enough heat, not even able to melt 1mm aluminium 5% mg mig wire with it. Will attempt to overdrive it with 36V to see if it gives the extra oomf it probably need. If not I'll have to build a spot welder instead.

Something struck me the moments before I bought this, so I'm reaching out to see if anyone tried building a sinter with this instead of using a laser. Granted it might be a lot slower. But I'd feel safer with this than a laser, lol.

Also, these 3d-pens should prove to be a nice challenge to hack to be able to swap the filament for weld solder or similar. I guess none made that hack yet either.

Keep me posted if you do. I will surely look into it at some point. Everyone should need a miniature welder.

I've seen such when I went on http://mobilefireunits.com/ and some other trainings. Today, these are very required to have on some machines.

I have a project using a 12VDC supply where I need to control one of these from a control box (switch) that's about 40 feet away from the igniter - the problem I'm having is that the voltage drop across the 16ga wire I'm using to connect them is too great (the voltage measures a bit over 9VDC when the igniter is connected), so the igniter isn't getting hot enough. Should I just try to find a 15VDC or so power supply? Any suggestions on where to get a UL listed 15VDC supply that could power this without breaking the bank? Thanks!

As you've found, due to Ohm's Law, there are only two ways to solve a voltage drop on long wire runs: reduce the resistance of the wiring (smaller (thicker) gauge), or up the voltage. AWG 16 is already pretty hefty, you could try switching to 12/2 RomexTM which is fairly cheap but bulky to run. Switching to a 15V supply is a good option. We're looking at carrying higher-voltage higher-current supplies, but don't have anything lined up yet. You should be able to find what you need at Digi-Key or Ebay.

But while you're working the problem, ensure that your existing 12V supply is beefy enough to supply the igniter. Given your numbers you should only be seeing about 1V drop. A 3V drop could be a supply issue (note that the igniter will draw 5 or 6A when it's first fired up). Good luck!

Thanks for the reply, Mike! I think my tests were actually with a 100 ft cable (an orange extension cord with the ends chopped off), so that probably accounts for the additional loss. I'd like to avoid Romex, so I was thinking of using a switch on one end of the cable, and a relay or an N-Channel MOSFET on the other end, and having that switch the power supply and ignitor, so they won't suffer the loss from the long cable... as long as I have a resistor pulling the gate to ground, would you expect any problems using a MOSFET in that way? (I don't know much about them, so I don't know if the long cable would be likely to pick up "noise" that might trigger the MOSFET on its own, or not?)

The other question I have is, why do these things have .110 Female blade connectors? They are pretty difficult to find! :) The female connectors seem to be available all over the Internet, but the male blades are harder to come by. I found them at digikey, but they don't seem very common? I'll likely just chop the little guy off and replace it with a more standard sized blade.

I received two of these -- which look identical to the picture, except they have tags on the wires that say 24V25W. Should I be concerned that the ones I received are 24V and not 12V?

This could melt aluminum or copper... cheap welder anyone?

I think I'll add a couple to my quadcopter so I can set off fireworks in the air. :D

So could we use a lower voltage and get a lower temperature out of it? This seems like a great solution for a soldering iron heating element.

Schematic for using with an Arduino? (Surprised this hasn't been asked yet!)

These need more voltage (12V) and current (4A when cold) than an Arduino can supply, which may explain your surprise. But you can use a relay like the Beefcake Relay Kit to safely switch the high voltage and current these need.

Correct me if I'm wrong, but the Beefcake is overkill for this. I had a project a year ago running a number of 120V ignitors with a ~1A draw off one of those 8x5A120V relay boards. I'm currently building a flame effects project that will involve a number of these ignitors & 24V solenoid valves, and if I've done my math right these should be able to be driven by a TIP120 circuit. The datasheet claims a max of 2.4A@12.85V, so 30W (or 48W if your 4A claim is correct). The TIP120 claims a max of 65W so it should be able to handle this load, especially as these heat up rapidly and the draw goes down.

(Note: I haven't actually got to the point of wiring this together, I'm currently running the prototype off one of the relay boards from the previous project. Regardless, a relay would still be fine, you can just use a much cheaper option than the Beefcake, with its 20A 240V theoretical maximum)

I'd recommend using a MOSFET. Even the lowly IRF510 shold work, but it will need a heatsink.

You're not wrong, but I tailored my recommendation towards the (assumed) knowledge level of the OP. The Beefcake relay is probably the simplest device we offer that will control one of these igniters from an Arduino. There are of course any number of ways to control large amounts of current, and if you're skilled with big transistors by all means use them.

My 4A claim was from playing with one of these on a benchtop supply; what I saw was that given unlimited current they'll draw 4A when they're cold, which will quickly drop to 2.5A as it reaches full temperature (these glow white, not red-hot). You can likely run them just fine on a 2.5A supply but note that it will probably current limit at first.

Thanks for the info on the 4A cold start, I'll make sure to design this project to handle that. I'm actually running this off a deep cycle battery and auto alternator, which means it'll be getting up to 14.5V if I don't also regulate it. Do you have any idea if the slightly higher voltage will damage them? Its my guess that it'd be fine as I'm betting these things are mostly used for lighting RV furnaces rather than household ones (most home furnaces I've seen use 120VAC ignitors).

Also - warning to the original poster and any one else: If you're making plans to use one of these to ignite any kind of flammable fuel, especially if its pressured, be sure that you really know what you're doing when it comes to the plumbing. Standard household natural gas is a pretty low pressure (probably 10-12PSI) whereas a fuel tank of propane can be 300PSI depending on the temperature.

Can these be run continuously? I've been looking for a small powerful heater.

They're designed to run continuously.

Potato cannon!!!!

Well now all you need is this, some PVC pipe, the solenoid valve that you guys sell, that air pump, and an Arduino with some circuitry. Slap it all together, add a lighter fluid fuel tank and bravo, Arduino controlled flame cannon.

Sounds kind of illegal...

Yet, surprisingly it isnt!

Probably depends on the state.

This is great, thanks guys! I've been looking for a less-expensive igniter for my pellet BBQ smoker project.

Does anyone think that it would be safe to use two of these as a spot welder system?

A spot welder heats the joint itself by passing a large current (the less connected, the higher the electrical friction), These igniters will only create heat on the outside surfaces of the joined material so I doubt you'll be happy with the results.

Probably, so long as the metal you're working with can be welded at around 1,300c.

Thank you, most of the things that I'll be using it on will be well below that temp.

Probably usable as a fireworks igniter.

Way too expensive relative to the likely uses you'll get out of it. Use a model rocket igniter instead, way cheaper.

Does anyone know the amount of time this takes to heat up from room temp to 1300 C

I too would love this info. Anyone?

I would not use this product for something that needs to ignite immediately. I would build in a delay to the code to start gas flow after a few seconds (until it gets hot) Plus im sure it draws a lot of power (not good for a portable project) For immediate ignition I would use the Spark Gap Igniter or the Piezo Igniter.

Spark Gap works great for igniting propane, you just need a small amount of wind buffer to make sure you catch the cloud as it passes. In addition to the comment on code delay, you could also add in a NG style thermocouple switch that will not allow gas to pass unless the igniter is hot enough.

Yeah, I don't know about how long it takes to hit the maximum temperature, but I just replaced the 120VAC ignitor I was using on a flame effect prototype with this and it seems to take ~5 seconds to ignition.

Thanks for the input but that doesnt help answer the question

Aprox: 17 seconds Source: Igniters

$60 at the furnace parts place.

oh thanks, I should raise the price then.

j/k

I was pretty sure I was getting ripped off at the time. The outside temp was -10 and I was afraid the pipes were going to freeze. $60 was cheaper than a plumber.

Yeah, it's unfortunate when you're stuck like that. I now keep a spare ignitor for my furnace. They're $15 on eBay (in a sealed factory box), $60 at the local HVAC store. Similarly, the 220v contactor relay for my A/C - TWO for $25 on eBay, $120 locally EACH - and the eBay ones were actually significantly better (sealed instead of open frame)

Is this a one-shot device or is it reusable?

re-usable. it's made for furnaces, so it's made to be used constantly, and withstand the heat as well.