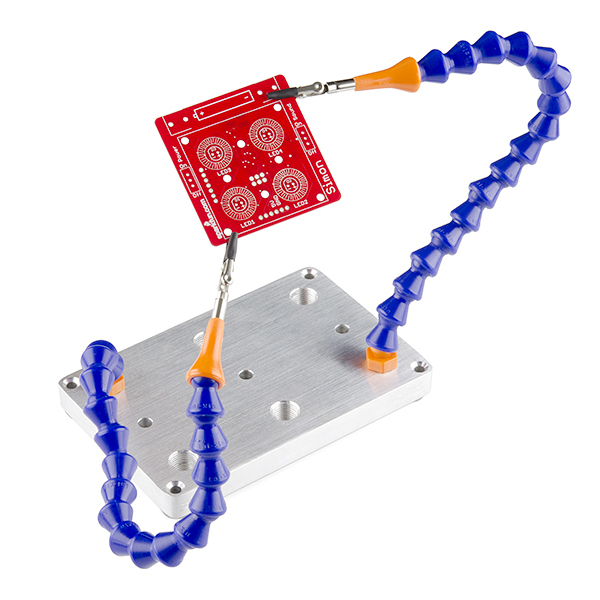

SparkFun Third Hand Kit

Are you frustrated with the lack of dexterity from most third hands? The SparkFun Third Hand gives you the ability to hold a board between two alligator clips on two flexible arms with multiple points of articulation. The arm's wide range of articulation gives you access to any angle of the board that you are currently working on, making soldering that much easier. The SparkFun Third Hand also won't move around while you work thanks to a heavy aluminum base supporting the arms.

Even though we give you two alligator clips for the flex arms, that shouldn't restrict their functionality to just holding a PCB. Add an LED for better lighting, a fan to keep solder fumes out of your face, or a magnifying glass to get an up close and personal look at what you are working on.

Note: For assembly instructions watch the product video below.

Note: A portion of this sale is given to Ryan for inspiring the design with his Instructable.

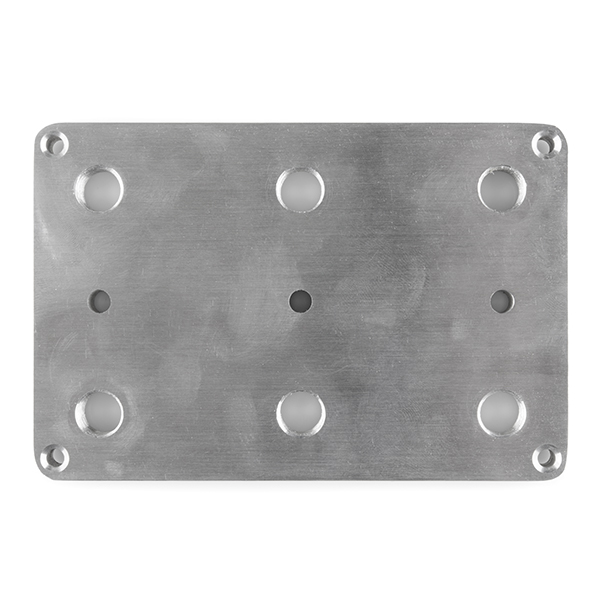

- 1x Aluminum Base Plate

- 2x Flex Arms

- 2x Alligator Clips

- 2x Alligator Clip Covers

- 2x 1" 6-32 Phillips Screws

- 4x Silicon Bumpers

SparkFun Third Hand Kit Product Help and Resources

How to Solder: Through-Hole Soldering

September 19, 2013

This tutorial covers everything you need to know about through-hole soldering.

Pokémon Go Patches with EL Panels

August 3, 2016

Add a cloth stencil over EL panels to create glowing logos and designs.

Computer Vision and Projection Mapping in Python

February 6, 2019

Use computer vision to detect faces and project images on top of them.

Assembly tip using channel locks

A fan and customer of SparkFun's shared a video of them using channel locks to demonstrate snapping the alligator clip tip into the blue ball socket of the assembly which can be a bit tricky. Seems to work like a charm! Just be careful when using tools and wear safety goggles whenever force is applied and shattering something is a potential:

https://drive.google.com/file/d/11orRYSymOaOOXrsHTHYfBb2K3q-UkQ9j/view

Assembly Tip

We have run into a few issues with the tips of these third hands breaking during assembly. SparkFun recommends when putting these together to soak the tips in hot water(coffee/tea hot, not boiling) for about a minute and then remove or place it onto the flexible arm. This will soften up the plastic a bit so it does not break while being removed or popped into place.

Core Skill: DIY

Whether it's for assembling a kit, hacking an enclosure, or creating your own parts; the DIY skill is all about knowing how to use tools and the techniques associated with them.

Skill Level: Noob - Basic assembly is required. You may need to provide your own basic tools like a screwdriver, hammer or scissors. Power tools or custom parts are not required. Instructions will be included and easy to follow. Sewing may be required, but only with included patterns.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

3.9 out of 5

Based on 63 ratings:

2 of 2 found this helpful:

Could not reassemble arm

It's a great concept however I found the assembly quite frustrating. If you purchase this I would recommend drilling out the bottom and feeding the screw though the whole arm. If you don't drill it out first, the screw will get stuck in the bottom. Then you will need to pop apart two of the middle arm pieces to push it out. I found these two peaces impossible to reconnect. I tried hitting the arm with a mallet while using a tube to keep the arm from bending but I eventuality melted the pieces after tying to heat them a few times. They are somewhat flammable by the way :)

I would not recommend this purchase unless you or sparkfun drill out the bottom piece first. I should also note that the arms that I received were different then the ones in the picture and video. They visually appeared to be of a lower quality. As such I would warn customers against popping apart the arms as you may not get them back together.

Hi, Sorry for the trouble. Check out this video where Robert explain how to assemble the kit. http://youtu.be/XdOG609ajBo?t=1m36s Thanks

2 of 2 found this helpful:

Hard to assemble but heat helps

After trying to muscle the arms back together for 30min I gave up and got out a butane torch and heated both the arm and nozzle. Snapped together very easily after that.

1 of 1 found this helpful:

I love it

I only can say, I LOVE this thing. I only wish there was a magnifying glass accessory available for it

1 of 1 found this helpful:

Good product, but be careful putting it together

Follow the advice provided by others regarding heating the plastic pipe ends with boiling water to facilitate popping off the end cap to install the clips. If you do, clear sailing

2 of 2 found this helpful:

Very "handy" but a bit tricky to set up

I love the convenience of the 3rd hand now that it's set up but it was a little tricky to pop the ends off in order to insert the screw and attach the alligator clips. I actually cracked one of the ends slightly but glued it back with no ill effects. I'd definitely recommend it to anyone, with the recommendation that you be careful popping the ends off!

5 of 5 found this helpful:

It's good... with a couple of exceptions...

I must admit - it certainly is far better than the third-hand thing you get with the magnifying glass at places like Harbor Freight and what was shown in the video. The arms are solid enough to hold PCB's, wires, etc., steady while you work on them.

Yes, popping the tips off IS quite difficult at room temp. One reviewer said if you can't pop them off by hand you have no business soldering. Don't listen to him. I certainly never would. Anyway, don't use anything extreme like a propane torch. A heat gun used for shrink tubing works great. Just turn it on the lowest setting, point it at the orange tip while turning the thing in your hand for about 10-20 seconds, then stick the tip in one of the holes in the base and bend it over till it pops out. Works great.

As to the alligator clips? Yes, use loctite on the threads to keep it from unscrewing accidentally and really, they should include BIGGER alligator clips. Unless you're holding small wire or a thin PCB, it's going to annoy you.

Also, you may want to get a couple of extra arms - one to hold a box fan and another to hold a fresnel magnification lens. Of course you'll have to figure out how to mount them to the tips - but it would be cool if Sparkfun offered those as options.

Aside from the small-ish alligator clips - the thing is great!

1 of 1 found this helpful:

Incredible Once Assembled

Once this product is assembled, it's great! The base is very solid and sturdy, and the whole unit is aesthetically pleasing.

My only complaint is in the assembly. It's nearly impossible to put together using brute force alone. I bought two additional arms with the intention of using four in total, which was fortunate, as I broke two of the headers just trying to remove them from their arms.

Update: I received my new set of arms. This time I followed reviewer John Price's suggestion and used hot water to remove and re-attach the tips. I boiled up a pot of water and submerged just the tip for 5 to 10 seconds, grabbed onto the tip with a cloth, and popped them off. Once I had the alligator clip attached, I submerged the base of the tip in the hot water, held onto the tip with a cloth, and popped the arm back in. The entire process was far easier than my first attempt. Installing the alligator clips on 4 arms took me no more than 5 minutes.

4 of 4 found this helpful:

Truly superior helping hand device.

The base is solid and heavy, and the flexible coolant pipes are durable and can flex to hold your work exactly where you need it. I bought extra hardware to make a total of 4 pipes+clips and now I feel invincible.

8 of 9 found this helpful:

Use hot water! No torches, heat gun, or drilling!

Good grief, there is no need for torches or drilling out the base which might cause damage. Just dip the end in hot water for a few seconds and pop it off. Attach the alligator clip, dip the cup in hot water again and you can easily push it on again by hand.

You DO need to be a bit careful in screwing into the base so that you don't cross-thread it. Be gentle and make sure it is straight and it will screw in easily up to the stop.

2 of 3 found this helpful:

Good product, assembly too difficult without lighter/heat gun

I received the 3rd hand kit and was excited to put it together. The first thing I did was try to take off the top orange nozzle, which I found incredibly difficult. With some leverage on to aluminum base described in the video, I was able to get them off. The second I took them off though, I realized that the inside of this arm was completely hollow and that I probably could have fed the screw in through the bottom had I straightened out the tube. After assembling the alligator clips into the orange nozzle and using a lighter to melt the heat shrink tubing onto the clips, the next roadblock was getting the nozzles back on. This is incredibly harder to do than getting them off, and requires enormous pressure to achieve. I had this kit stashed in an unusable state for a few weeks, with various attempts at reattching the hose. I even tried sanding away some of the plastic to get it to assemble easier but stil no dice. I had almost resorted to superglueing them on, but I remembered a comment someone left about using a heat gun to push the orange piece on. I don't have a heat gun, but I did have a ligher, and I found that if you hold the plastic nozzle a few centimeters above the flame, while moving the nozzle to give it an even heating, the blue socket will slip in with a little bit of force. After the nozzle cools, the plastic contracts and forms a nice seal around the socket. screwing the threaded base joint into the aluminum base was more diffucult than it should have been, requiring a set of pliers to tighten it all the way.

Overall I think this is a great product with some fairly obvious flaws. Firstly, they used the cheapest coolant hose they could find. removing the top and reattaching it for the kit was far more difficult than the assembly video implies. This wouldn't be such big issue had the instructions given the tip of using a heat gun or lighter to reattach the hose. The aluminum base is high quality and I can imagine the threads being quite accurately cut, however the threaded hose still required a bit of force to get in, which again is probably due to the cheapness of the hose. That said, the hose works well and the only advantage to a more expensive one would probably have been a nicer thread and easier to detatch links, which we're never going to break apart again anyway

I recommend you order this and (if you don't have one) order a heat gun

2 of 3 found this helpful:

not sure if i got the right partd

I'm not if it's me or the product but I'm have trouble with the clips fItting.

Please send information on everything fits together.

Hi, Sorry for the trouble. Check out this video where Robert explain how to assemble the kit. http://youtu.be/XdOG609ajBo?t=1m36s Thanks

1 of 2 found this helpful:

Awesome once put together, difficult assembly required

This thing is absolutely awesome once put together. My one complaint is that it doesn't come already put together. This took me about 30 minutes to assemble because the ends are so difficult to reattach.

Some people have successfully used pliers to snap it together rather than trying to push on it with about 100lbs of force, but even then it's not straight forward due to the curved surfaces. On, the other hand, +1 for beveling the edge of the aluminum base, otherwise my hand would be scratched up from when the tubes invariably slip and move around when you put 100lbs of force on them

1 of 2 found this helpful:

Easy to assemble with a heat gun in cold environments.

I found snapping the blue segments apart and putting them back together to be nearly impossible in my cold environment. A bit of time with a heat gun made it easy though!

1 of 2 found this helpful:

The arms should come assembled!

Whose bright idea was it to not assemble the arms before shipping it out to customers? I had 2 people try to help me snap them together and we couldn't do it.

The guy in the video makes is look so easy -- which only makes it that much more frustrating.

Finally had to use a heat gun to heat up both sides and then the parts would actually snap together like the video shows -- so I call shenanigans on that video.

Once assembled it's fine, but why frustrate and anger customers and not just ship the arms assembled???

Sorry for the troubles. Those little nozzles can be pretty stubborn from time to time.

1 of 3 found this helpful:

Great concept, decent execution - room for improvement

Aluminum block and flex arms are great. Additional flex arms are also a great value.

There's room for improvement and it's easy-ish to accomplish.

The stock alligator clips are too small - too short, jaws don't open wide enough and thumb lever too small.

The clips need to be able to rotate on the flex arms but not come unscrewed - that means locking up the threads. This can be done a number of ways: threadlock compound like Loctite, set-screw into the side of the clip thread body or the easiest to ship in a revision, a nut to be placed on the bolt BEFORE the clip for the clip to tighten up against.

As an aside, anyone that can't follow the directions in the video for popping the flex arm apart AND putting it back together really has no place working with a soldering iron. It requires some force, but it's no reason to get frustrated, it's simple. If you understand how these flex arms work, you wouldn't be complaining that it should be easier.

Much cooler than the one I had before.

This product is bigger, better-built and more versatile than the little gizmo I had been using. It does vibrate more, but this hasn't caused any real problems so far. The big knobby blue things are totally outrageous looking but do the job quite well.

Clunky

This in theory is great. The alligator clips are very small and when you heat wrap the ends to reduce the scratching from the clips, you lose even more width of space on the clips. The overall assembly is a PAIN in the neck. As in the orange ends don't pop off very easily in order to screw the roach clips on. i have tried heat guns to soften the plastic and my thumbs became raw. The overall rigidity is too tough, perhaps it will loosen up with use - much use Im sure since they are very taught. But I guess better then lose and sagging when needing them to hold in position. Overall 3 out of 5. It's not perfect, but it works better then the stiff arm 3rd hand products. Also it's very weighty so that's a good thing. Just be sure you have strong hands and or gloves to assemble it. Yes I followed the video on here on how to do it for tips, but it didn't work.

I cracked the orange piece during assembly

I guess I should have read the reviews and tried using heat. I really wasn't expecting it to crack. I figured these must be able to handle the separation of the orange tip from the blue hose or they wouldn't expect me to assemble it myself. So, yeah, a little disappointed out of the gate. I do have high hopes otherwise since the base is so heavy compared to my other third hands from the Shack.

Hello. Sorry to hear you're having trouble with this kit. We have found soaking the arm for 30 seconds in hot water fresh out of a teakettle (fresh hot coffee temperature water) seems to soften the plastic enough to prevent cracking and make it much easier to disassemble/reassemble. Don't worry, we will get you taken care of!

Handy

It works great. I like how I can add hands to it or move hands.

Third hand indeed!

Really helps you in holding thinks the way you want. A couple of things: - Double layer those alligators teeth with the sink or it will have scratches in your boards; - As someone said, a lighted mag in this would be "SWWWEEEEEEETTTTT" (thumbs up for anyone who figures who says/said sweet).

Quickly replace existing 3rd Hand

This has far more range of motion than my existing 3rd hand. Replace existing 3rd hand in minutes. I did replace the smaller alligator clips with larger ones by machining some round brass stock (Center drilled in lathe then tapped 6-32), then soldering the new brass inserts into the larger clips. Will be adding additional arms next order.

Great idea, one big flaw

The plastic threads on the arms and metal on the base don't seem to be the same. I have 6 arms and a few will only screw in a half turn. Feels like the threads don't match. I havent tried all of them since the plastic threads will deform if forced. And I'm sure they already have.

I'll buy some more arms if anyone can confirm the threads do indeed match.

A little over priced

It's pretty expensive. I feel like it could be a little less expensive, but it does work really well.

This is such a great product.

I don't need a soldering vise when I have all these arms.

Exactly what it looks like

Try to solder almost anything and you will soon find you need something to hold everything in place. Other 'third hand' solutions look flimsy and inflexible. This was much more expensive but why have a hobby that is frustrating?

The only problem is that it is a little tricky to assemble but if you are careful, take your time and follow instructions it can be done without breaking anything. Hold the 'just the tip' in boiling water for 20-30 seconds and pull them off with your fingers or use the base plate (see Sparkfun video).

I was worried that the flex arms would not be stiff enough but they are just right. Even if they eventually wear out they can be replace cheaply enough.

Purchased as a gift

My husband was thrilled!! He is the ultimate "do-it-your-self" type person, from circuit boards to woodworking. He has already used it a dozen times and is very happy with it.

Great idea with room for improvement

This variation of the 3rd hand is everything the description says it is. And that's great! But it isn't perfect. Like every other 3rd hand, it's still difficult to get the clips lined up with the millimeter accuracy you often need. There's still the usual "over bend, and hope it springs back to the right position" trial-and-error. Taking a few sections out of the arms helps somewhat, at the cost of reach and versatility. Next, while you can certainly attach things other than alligator clips, this isn't a modular, plug and play system. You'll have to engage your maker creativity, and that takes time. The last two gripes are nit-picky, but things you'll notice, nonetheless. Once you get the orange tip of the arm off (no easy task, which visibly stresses the plastic), slide the screw in, and begin to tighten the clip on, you'll see the neck start to bulge as you get the clip tight enough to be stable. Even then, I never felt like I could get the clips as solid as I'd prefer. Would pan head screws possibly work better? The included alligator clips are what you'd expect, though the threaded part is a particularly nice addition. But for holding anything other than wires or credit card size PCBs, they're too small. Having a selection of different sized clips (WITH threads) would be a big advantage (though once you unscrewed one, the screw would slip down into the arm...).

The base is amazing, though. 10/10.

Much better than traditional helping hands

I used to use those traditional metal "helping hands" for years for hobby electronics work. While they technically worked, they were always finicky and tedious to use because you had to constantly adjust the tension of the wing-nuts that hold the joints together. And the arms usually had limited range.

These, on the other hand, are much more hassle-free to use. There are no wing-nuts to worry about and no ball and socket joints to come loose. And these have more positional degrees of freedom than traditional helping hands. You can bend them into almost any configuration imaginable. And the solid aluminum base makes the unit quite sturdy. It's pretty much impossible to knock it over by accident.

This model comes with two arms but the aluminum base has six drilled and tapped holes to allow you to add up to six arms total. I'm going to buy an extra pair or two of the arms (https://www.sparkfun.com/products/12783) and alligator clip hardware (https://www.sparkfun.com/products/12033) to add to my existing unit.

Overall, this is a great product and I recommend it over traditional "helping hands" models.

Assembly will leave you wishing you had a fourth hand!

Well, I finally finished the assembly of the SparkFun Third Hand and overall I found it to be a frustrating experience. Hot water didn't work for me, but a hair dryer eventually did the trick. I purchased two additional arms to bring the total to four and I'm stoked to start a new project. Robert's trick to snap the arm segments back together definitely came in handy!

Echoing the responses of previous reviewers, I'd sum up the Third Hand with the following pros and cons:

Pros: - Very stable base - Supports up to 6 arms in various configurations - Assembly will help you develop the superhuman strength Robert displays in the product video

Cons: - Alligator clips could be larger and stronger - High likelihood of injury during assembly - Lack of additional accessories from SparkFun (e.g. magnifying glass)

Fine product

If anyone has a way to reattach the blue knuckle back together I would appreciate it.

Hello! Have you tried letting the knuckle sit in a cup of very hot water for 30 seconds to let it soften a little? Typically that's how I change the lengths of the arms on my setup.

Disappointing

The base is flat, heavy, and better polished than the photo shows. It's useful for bolting things down as a heat-sink, but that's about it. The alligator clips are a bit small compared to the arms, but ultimately work. The problem is the arms, which seem to be repurposed flood coolant sprayers from a CNC mill.

Every time I've tried to use this as "helping hands" I've found them simultaneously too springy to hold a board/part rigidly enough, and too rigid to adjust finely. Adjusting them means overcoming the friction of the individual joints until they'll move, after which they'll move too far. I found it near-impossible to position them accurately enough to be useful, especially compared to the traditional chromed-steel ball-in-clamp helping hands.

For holding boards I eventually got a panavise-style holder which has worked much better.

Works well but very, very difficult to assemble without breaking.

The alligator clips REALLY need to be placed on their yellow, plastic holders (arms, or whatever they are called), and the yellow, plastic holders need to be placed on the blue, flexible, plastic arms at the factory before they are shipped to the customer. I found it to be extremely difficult to put back the yellow, plastic holders onto the blue, flexible, plastic arms after I had inserted the alligator clips into the yellow, plastic holders. In fact, in the process of doing this, I unfortunately managed to crack both of the yellow, plastic holders. However, for the time being, these cracks are not preventing me from using this device (which works well, once assembled).

Junk

The video explains how to put the clips into the nozzle. Looked simple. The first nozzle separated easily and the alligator clip was inserted. The second nozzle cracked and the separation point was after the first blue articulated piece. The nozzle could not be repaired. Willing to try again, I contacted Sparkfun and asked for a new arm. Received no reply to my email. I'll find some other use for the aluminum base. It is nice and heavy, but the plastic arms are useless to me

Hello!

Sorry to hear about the issues with the third hand kit, sometimes they can be really hard to work with. Our records show that you contacted us on September 7th (case # 244778) and one of our customer service representatives responded to you that afternoon requesting additional information. I'm sorry if the response got mixed up. Please contact cservice@sparkfun.com or techsupport@sparkfun.com to get this issue straightened out.

Just the best

Upgraded from the typical cheap 3rd hand, used the boiling water method to assemble worked like a charm

A very sturdy helping hands device

I love the heavy aluminium block as a base. Makes for a very stable working area. The arms are flexible enough to manuvear into the weirdest of positions, but stiff enough so I can solder stuff without moving it. Hell through a peltier on the bottom and it could double as a soda can heat sink! As other comments have said, getting it assembled it the hardest part. I used a kitchen blow torch at a very slow setting to loosen up the plastic. A heat gun would be a better option. Be careful when trying to put the tips back on, I bent one of my alligator clips and it broke. Luckily I had another to use!

Solid, sturdy, and useful

This works much better than any other third hand I've used. I'd like to see an option for larger clips, but the ones it comes with work great. The heat-shrink for the tips is a nice touch.

Shattered immediately.

Even following the instructional video wasn't enough. Step 1 from the video is to try to snap the hose end off. Well don't it will shatter immediately. Other people have suggested dunking these things in boiling water first. I guess I'll try that.

SPARKFUN: PULL YOUR VIDEO! It'll just cause more harm than good!

Sorry to hear you're having trouble! Please contact our technical support department and they can assist you with this.

Third Hand kit

This is a great tool that works as described. It is a little hard to put together, but once assembled, works great!

I’m glad I made the purchase.

Concept is great! Works if you can get it assembled.

Needing something to support my soldering work while using my not so steady, old tremoring hands, I read the reviews fraught with all peoples' problems. Watched the video, decided assembly would not be beyond my 50 years' engineering experience, and ordered one with extra arms to have a 3rd, 4th, 5th and 6th hands.

Not! The guy doing the video must be a Super Hero! Getting it apart was difficult but getting them back together was nearly impossible. The joints must be tight fit to be rigid enough to stay in position. I decided to try hot water on the orange part and ice water on the blue to facilitate snapping together- unsuccessful. Reasoned that the temperature difference needed to be larger.

One part in Kuerig heated water and the other in 0 degree freezer crushed ice (no water). This enabled snapping the parts together if you waited long enough and hurried the assembly. Still difficult but doable.

Happy that it'll maintain enough stability that I can apply enough pressure to steady my hands. Back into hobbies again!

Pretty Good

Compared to other third hand kits this one is pretty good. It's a lot more stable because of the increased weight in the metal base and the hands are stiff enough without being difficult to adjust. I do wish the base was even heavier though because I find myself spending a lot of time trying to position boards in just the right place above it so they won't move when I solder things on them. If it was 25% heaver it would be perfect I think.

Great product, very useful!

This has been a great product to use! The flexible compared to the traditional style of helping hands has been much better to use! My only complaint is that I broke one of the arms when assembling and had to use a dremel to remove the broken section from the test of the arm. So one of my arms is 1 link shorter than the test! Ha!

Overall, spend the extra money on one of these vs the cheap kind you can buy everywhere else!

Can not install clips to arms

No instructions were included. There is no way to install the clips to the arm. The screw head will not fit down the tube from the bottom. The joints do not appear to separate to insert the screw without breaking them.

Check the assembly video for directions on how to assemble the kit.

One thing you might want to do is heat the parts in hot water for a few minutes beforehand as that will soften the plastic and make it easier for you to disassemble and reassemble them and will help prevent breaking any of the plastic bits.

Nice Kit

Easy to assemble, and works great. I would definitely recommend this to someone looking for a good quality 3rd hand.

Good, could use bigger clips

I had no trouble assembling it. The pipe joints are easier to pop apart than the yellow tip is. I separated the joint just behind the one at the tip and could still drop the screw in and connect the alligator clip. Bigger alligator clips would be nice. The ones supplied are probably made by Mueller, who make bigger ones with a threaded barrel, but those take an 8-32 screw. You can get them from youdoitelectronics dot com ("...128 when it's dark outside..."). Just throw out the covers. We might have to drill out the tips to 5/32". It would be nice if someone sold a magnifying glass or LED add-on kit.

Incredibly Clever and Tweakable

This is a great use of off the shelf parts, and I had none of the issues as reported by other reviewers. Snapping off the ends of the sprayers to install the clips was a breeze. I added my extra set of arms I ordered and now my brain is abuzz with ideas for what to screw into the remaining holes.

Very nice and helpful tool

I have been using this recently and found it very effective. It has helped me with some very difficult to hold tiny wiring to a small motor that was still physically and loosely attached to a clockwork. It was also used for a cabling repair where in the past I had to hold and solder connections by hand. A very useful tool.

solid helping hand

much more versatile than the articulated arm types, which I also have. Also has a greater reach and the ability to move the arms, or better, add a third (say, for a magnifier).

Great Gift!!

Bought this for our son on this last birthday & wow was it ever a huge hit!!! He LOVES it & it does make his soldering projects so much easier!! Thanks!

0 of 1 found this helpful:

Been wanting one of these for a while!

I have had the traditional 3rd hand rigs with the magnifier and they just dont get to where I need to go. So with a gift certifcate from the recent holidays I was able to get the SparkFun Third Hand Kit.

It didnt come with assembly instructions, but seems obvious what needs to be done. I tried to take off the conical end to put the screw in for the clip. That was a bit difficult but I thought there must be an easier way. It turns out that if you drill out the yellow connector on the other end to allow the screw head to pass, it will go all the way through the tube and connect the clip nicely. No screwdriver required.

Note: hold the part you are drilling in a vice so you dont spin and loosen the connection to the blue bits.

Not long after, I was doiing some work under the dash of my car, and this was just the help I needed to solder some wiring. Its a really sturdy build. I will probably see about adding an additional arm or 2 down the road.

Great kit!

0 of 1 found this helpful:

Once put together, it's awesome!

Like other reviewers, I had a horrible time reattaching the yellow tip once I'd installed the alligator clip. I finally saw advice to use heat, which really worked (a propane torch is so handy!) but BE CAREFUL! The plastic is fairly heat resistant, but once it's at temp it gets soft/melts quickly.

That all said, it's DARNED USEFUL now that I'm using it! It's nice and stiff but flexible and definitely stays where you move it. I'm considering picking up two more pieces for other parts (magnifying glass and LED light come to mind.)

Great idea, great execution!

I've used this product a few times now; each time was soldering to semi-small PCBs. The kit has been wonderful at holding position and adjusting to any awkward angles.

My only gripe was the amount of force required to install the alligator clips; taking the nozzles off was quite an interesting time!

Thanks to Ryan for the design, and I look forward to adding more arms to the kit in the future.

Nice idea but needs heavy duty Alligator clips.

After purchasing a few of these units for use at the University of Colorado College of Engineering I found that this cool device has one very distinct problem. The Alligator clips are too small and fragile, they shear off right at the threaded sleeve. They are held on very well with the screws but the metal section that connects to the threaded sleeve is very thin and weak. It is time to redesign this product. Considering that this product costs about 4 times as much as the original third hand is should out last and out perform it.

Great Tool

I'm new to soldering so I can't say what working with the more traditional third hands is like. This third hand kit is amazing. The arms can be twisted in to just about any configuration that you want. I want to order more arms and clips but at the moment SparkFun is all out of the alligator clips.

An option for bigger alligator clips would be nice for holding on to larger items.

Neat idea, but in practice its hard to position precisely

The concept is cool. The metal base is great. Alligator clips are so so. My biggest problem is that it is hard to precisely position the arms. This is because the plastic joints don't slide smoothly, but instead they move in jerks. I actually thought about putting some lubricant in the joints but haven't tried that yet.

The best

This thing puts regular helping hands to shame. It was simple to assemble, didn't need to use heat guns or butane torches. Just watch the video. Great product!

use a heat gun to assemble

Great idea and works fine once it is assembled. After cracking one of the yellow endings and reading the reviews, I applied about 15 seconds of heat gun to the yellow part and then it snaps right in.

The alligator clips should be bigger ones, I bent one of them while tightening the screw. Might want to use lock-tite on that connection.

Edit: Sparkfun was great about replacing the part I broke. This works so well that I ordered a second one as a gift.

Hello! I am replying to your email now. We will get you taken care of.

A great third hand but an absolute pig to build

I'm a man of average strength and it was really hard for me to pop the nozzles off and impossible to reinstall them. I broke one in the process. I finally took a sanding disc and shaved a hair off the end pieces of the pipes. If you do that, be careful to take off the minimum necessary amount: the device depends on a tight fit to hold the alligator clips in place.

It's a great device but I honestly wouldn't do it again.

Much better than the typical third hand kit.

The arms are flexible but hold steady while soldering or doing other fine work. Great for students who are learning to solder.

Definitely the best third hand that I've used

I had one of those old third hands with a magnifying glass which is not easy to use. This is much more versatile. The hands can be a bit stiff to position correctly, but once you get them in the right place they don't move. Make sure to put the heat shrink on the clips cause they can scratch whatever they are holding on to.

I didn't have very much trouble getting it assembled. It wasn't that easy, but the techniques they show in the video work well.

This is junk. It comes with no directions on how to install the bolts. I broke both brittle orange caps trying to remove them. Now I'll have to glue the clips on. Terrible design ! How can you keep selling this ?

At time of writing, this is out of stock on Sparkfun. Fortunately, DigiKey has some in stock. They even send it in a red Sparkfun box.

https://www.digikey.com/short/z4j1qh

Pease update the drawing to show the right callout for the threaded holes to match your coolant pipe (1/2 20)! I assumed the drawing was right, drilled and tapped 6 holes to M14 1.25. My bad, should have double checked, or searched the comments...

It is almost impossible to assemble manually without damaging the equipment or yourself. Unbelievable that it is still shipping unassembled or without the warning that you would need a loc line connector tool.

The video is misleading too. The one on the video is either of another material , or somehow heated to make it look like it is easy too assemble.

I try to add some accessories to the base, but I can't find fitting screws. The plan indicate M14 screws, but that's not fitting. Has anyone a reference online that actually works?

Someone below indicates 1/2", but I don't know the step. Is is standard? it seems really fine...

Ok, it's actually 1/2" NPT. The drawing is inaccurate, that's a shame.

By the way, I bought a pack of M14 bolts I have absolutely no use for. Thanks a lot...

I like the idea of getting rid of the center three holes and machining a recess to act as a small parts tray. Maybe even another 4 smaller areas between the threaded arm holes.

Indeed, I was about to suggest some shallow bowl-shaped areas!

Oddly enough, I started thinking about that when seeing the thumbnail for the product, where I initially mistook the silicone sheet sitting on the base to be a wedge-shaped depression to place loose parts in.

What about a hole for a soldering iron holder like what the Third Hand (TOL-09317) has?

And someone said "What about a LED for light?" That's also a great Idea.

@AustinSpafford - shallow bowl-shaped - Great Idea !!! One bowl to hold your solder sponge. A second to hold parts and what ever.

I also really like the comment by @Pauld001, down below, the for a good magnifying glass.

But then you also will need a spool holder for your solder too.

Sparkfun could sell all these other things as additions to this.

Would love a light and magnifying glass attachment.

All this is a perfect electric Engineering project. Why not do all this for fun. It will be cheaper. You could add an LED Clock. Or perhaps if your working on an important project a pcb sized lock box.

What legal circuit would a person be building that they would need a lock box?

You don't have cats do you?

Great idea! I'll keep that in mind for the next bulk order. Hopefully it wouldn't add too much cost.

I really wish they'd made more, or I'd checked the site earlier in the day on Friday. I would love one of these. I'm teaching electronics to a couple of ten year-olds and they find using a regular 3rd hand even more frustrating than I do. When I get mine, I plan on adding a magnifying glass and a light source.

As for other people's comments about it being too much like an ordinary 3rd hand: are you kidding? Yes, it performs the same function, but it looks like you can get it in position far faster, plus it has greater overall range. I think this is well worth the price. Apparently a lot of other people do, too, since it sold out within hours. :)

Is there a Magnifying glass that attaches to the arms to help with us sight challenged individuals?

I had one of these sitting around: I hot glued the outer ring and glass to the end of a flex arm. Works great!

Looking through the dimensional drawings, I'm 95% sure this product actually uses 6061 aircraft aluminum, not 6160.

You are correct, I'll change it.

Fixed :)

Probably not enough to be "Mug worthy", eh? :P

I bought one based on the video. It's just as they claim, FAR superior to my old 3rd hand from Radio Shack. I thought the guy in the video was a bit theatrical when he tossed his old 3rd hand model in the trash. Nope, he was right. I just deposited my old one in the same receptacle.

Add a valve and air to either cool off parts or blow away solder fumes....

On the dimensional drawing the hole call out for where the coolant pipe screws in is M14x1.25 but on the flexible coolant pipe page it states that the end is threaded to 1/2" - 20 pipe thread.

I don't have the flexible pipe yet to double check but I am assuming one of these call outs is wrong? I decided to build my own set and don't want to tap the wrong holes.

I love this device and I use it all of the time.

For those folks wanting larger alligator clips I would suggest going back to the original instructable (link in the product description). The instructable calls for using larger alligator clips and attaching them to the arms with banana plugs. I was able to do this with one of the arms by heating up the threads on the banana plug so that they would soften the plastic on the nozzle enough to allow me to screw the banana plug in. I like the banana plugs as I now have the option of removing the alligator clips and then attaching something else with the same size hole in it.

I found the pipes impossible to click together—until I warmed up the socket end with a hairdryer. Much easier.

I was really excited to get my new third hand in the mail as I've used my traditional one quite a bit and find it flimsy and hard to get wires aligned in order to solder them together. Well, this one is even harder to get my wires aligned. I'm not sure if folks are putting some kind of lube on it to make it move more easily, but I'm having a tough time using this. Any tips?

I had trouble like some others getting the nubs reattached so when I finally found a way, though likely not the most intelligent approach, I decided to capture it - example.

does anyone know the tap size for the coolant hose? i guessed that it was the same as the one used on the third hand++ (1/8-27), but that definitely doesn't match this one.

Expensive for what it is, but i've found it very useful many times. If you're handy enough and want to save money, you should buy the flexible pipe and other bits separate, then build your own base.

I just got mine and they look great!!! The only real downside is that it is until now impossible to reattach the nozzles after they have been removed (that in itself wasn't easy). I have strong hands normally don't have problem with things that are handled with brute force but that is not enough here. Else it is a really nice product but useless if I don't get it assembled again. I guess I have to sand it until it can get back on. I have tried with boiling water but that doesn't help one iota. This is not a product for children and fainthearted people.

I blocked the yellow bit in a vice and pushed like mad the blue part. It worked. Roll the yellow part in paper in order to avoid to get it scratched by the vice. And don't crush it with the vice...

Neat little trick Mike showed me - place the nozzle into one of the open holes on the base plate, and use that as leverage to reattach it to one of the arms. Hope that helps!

Almost $30 for the base plate?

It is ironic that this is under the hand tools section.

Not that it really matters, but mine didn't come with any silicon bumpers. Also the "alligator clip covers" are just heat shrink tubing -- nothing wrong with that, but it's slightly misleading. I would personally go with slightly shorter flex arms. You can shorten them yourself though, which is nice. As some people have noted it's really hard to get the nozzle off. I ended up removing the nozzle and a few joints and threading the screw from there. I'd suggest some thread locker or other adhesive on the inside of the nozzle since the screws and alligator clips rotate easily in the nozzle.

http://www.loc-line.com/index.html: There so many useful applications for this it's crazy. "Where have you been all my life", that's all I thought when I discovered this product line. I built a fume extractor out of their anti-static 2.5" vacuum hose, anti-static 4.5" round nozzle, 120 mm case fan, and 12v power supply. In addition, you can add an optional speed control if you want (e.g. PWM). Then I just made a mount for one end of the hose to fit in a partially open window pane ( basically a tall rectangle, at least for my window, that seals the opening). Since it's flexible you can position to your working area! Thank you spark fun. It's only because of this site I discovered this product :) .

you should link to the pipes https://www.sparkfun.com/products/12054 from this page.

Why is this in hand tools? It is not like you hold it in your hand while using it. Just wondering.

It would be nice to have bigger alligator clips as an option. I have had problems holding onto pcb's securely with the heat shrink tubing applied. I still think it's a great product, though!

i put the part number for some larger & stronger clips in my review here: http://theksmith.com/consumerism/sparkfun-third-hand-review/

Wonderfull!! What a great idea! I bought one and use it everyday at my workbench. FAR FAR FAR superior to the old Radio Shack 3rd hand. I now have 5 hands when assembling, wiring, soldering my small robots.

I recomment buying an extra arm to go with the 2 that ship with the base.

Yes, screwing the plastic arm into to the aluminum base can be a little tricky. Take your time. You only need to do it once.

These are so insanely useful. I love mine! :)

Now you've got me thinking about using a Noga-style arm like this: http://www.shars.com/products/view/1456/Test_Indicator_Holder_Arm_Only

I don't know how well the no-name clones compare to an actual Noga, but it's something to think about.

Well I got this as a gift for Christmas and there is obviously no quality checks at sparkfun since the screws that came with it are the wrong size and don't even screw into the alligator clips. Thank you for taking the wind out of my sails ....

that's very strange. we'll look into it. in the meantime, can you email customer service and let them know? they can take care of you and get the correct product for you. sorry about that.

FWIW, this happened to me, too (also a Christmas gift). I'm emailing customer support as well and will probably see if I can get the right screws at the hardware store.

I just received mine yesterday and guess what? I've got the same problem too, but only on one of the arms. Fraction annoying, but I guess that is what the hardware store is for.

Apart from that it's a really good product and it should be really useful. I'm planning on using some aralditie to glue the magnifying glass from the other third hand (TOL-09317) to this one. Hopefully it will work ok.

Instead of a somewhat fixed custom aluminum base plate you can also use fitting pipe T-pieces (3xfemale) and straights (male-male) to form an easily extendable base as needed.

How are you supposed to put this together? One of the pieces I was given doesn't even fit the base board (I'm guessing it's one of those "oversized" ones that keeps getting mentioned), and there is no way that I can tell for attaching the alligator clips to it. I also did not recieve any of these 4x silicon bumpers.

Between the missing pieces, the wrong pieces, and the lack of instructions I'm very disappointed in this product. It looked really cool, but the version I got at least seems completely unusable.

Edit: Figured out that you have to snap the end pieces off. I was really worried about breaking something, especially since there were no instructions. It may not be a bad idea to ship these with the nozzle tubes off.

Further Edit: Okay, this thing is impossible. I don't know if I just got a really messed up hose or what, but I'm about to put this damn thing through a window. It's next to impossible to put the nozzles back on the house once you take them off, but that's the only way to screw the alligator clips in. Multiple people in my house have tried, but the thing will not go back together. Between the lack of quality control (missing parts, wrong parts) and difficult assembly I would strongly push people away from this product, despite how cool it looks in principle.

Yea, 100% agree with this.

I ordered the kit and neither of the two arms fit into the base. In addition, one of the ball joints cracked when installing the end piece (the clip holder) exactly as per the video instructions.

I was sent two replacement arms, one of which fit and one of which did not. On the one that fit, the ball joint at the base was so loose as to make this completely useless.

Basically, it seems that SF should have just used Loc-Line instead of messing around with cheap, poor-tolerance, brittle knock-offs. This product is not ready for prime-time and in my opinion should not be sold until the issues are fixed.

Having said all that, SF gave me a refund so pretty good customer service despite the poor product.

I got one of the first versions of this and had better success with it. All of the parts were included but I found that the included alligator clips weren't as long or well made as those in my cheapie helping hand from Harbor Freight. I ended up using my better HF clips and just crimped them onto similar sized screws as those included in the kit.

The nozzle is hard to get back onto the hose, I had the most success when I put the tip of the nozzle into the base (hang part of the base off the edge of a table to get full clearance for the tip) and snapped the hoses on that way. It's a tough fit for sure.

One this is for certain, they aren't going to fall of by themselves.

Please make more

Please make more of those. Unfortunately it's impossible to get the 1/8" snap flow/loc-line hoses in the EU. If anyone knows an online shop that sells the SMALL 1/8" hoses please let me know. Elsewise I rely on you guys at sparkfun to sell the kit again!

who long are the fles arms?????

dam this thing needs a peltier beer cooler as well....and a.....and a....and,,, coasters would be great so i can slide from one side of the desk to the other.....

got mine in the male to day i found a great led with power supply at ikea's scratch bin for $3 it works great....

I just received mine and it seems the holes in the base are just slightly too large for the arms. They just slide right in and out and won't secure at all.

Mine too. I have a call/email in to customer service but the floods are obviously slowing things down. I'm a little bummed.

we're addressing this. as it turns out, we got two different sizes of hoses. contact customer service and they'll take care of you.

Good to know, Robert. Thanks!

Use a bit of paper towel to fill in the gap. It should allow the threads to fit snugly.

The fit and finish on these are pretty poor. Wrong thread size, sharp edges, and a lot of cutting lube on the aluminim block.

That being said, it works pretty well. Having the parts held high off the workbench while soldering is surprisingly easier on the eyes and neck.

Huh! Interesting use of coolant hose! I like it!

For people who really want to get jiggy with this, you can get sets of coolant hoses from people that actually expect you to use them for coolant. Here's a set of similar 1/4 inch hoses:

http://www.grizzly.com/products/1-4-Adjustable-Coolant-Hose-Set-with-Pliers/T25180

Note that the "hose" itself is a series of plugged together sections, so there should be nothing stopping you from connecting several into a longer hose, or removing links to make it shorter. Note that the kit comes with the tool needed.

They also have 1/2 inch hoses in a similar set, for when you REALLY need it.

I use one for coolant and it works just fine!

About fell out of my seat when I saw the price for these. I'll pass.

How many were originally ordered? They went fast!

More Units please !!!

Anyone knows about an EU distributor carrying this? I could use one of these, but the shipping from US to France is crazy :(

Give it a while. We don't release upcoming products to our distributors before the rest of the world, so the distributors just found out about it today.

Doesn't this infringe upon the Creative Commons "Non-commercial Share Alike" license of this project? http://www.instructables.com/id/Third-Hand-A-multi-use-helping-hand-for-electro/

The instructions for making the project would fall under copyright law and the CC license, but the object would likely have to be patented to receive protection.

Only if they copied the text verbatim. That guide is not a specific design (e.g. a schematic) or a patent. It contains a parts list, and a set of instructions for how they may be used. That same information is provided here too, only the parts themselves are for sale.

Lots of people have built these over the years, myself included (http://shiftycow.net/diy-3rd-hand/). I was inspired by rstraugh, but I'll bet that many people have thought of this independently.

This product is fair game. After one year of an invention not being patented it becomes fair game in the US and it can never be panted and can be made by any body! Also I don't think this can be panted as it is two similar to helping hands which is clearly not panted as many people make them.

Also why would spark fun give money to rstraugh? Unless somebody owns the right to a product there is no point in giving them money!

I could be wrong, but thats the way I see it.

Improvement patents do exist, IIRC sewing machines went through at least a couple of patent iterations to get up to where they Today.

That said, they did mention they got the idea from a third-party, Don't Be A Dick law says they should give the guy a cut or a maybe couple of According to Pete stickers and a hug.

"Improvement patents do exist" Well that is obvious, however, there must be a noticeable improvement. I don't see much of a difference between this and the regular helping hands. They both grasp the object the same way. The only difference is this one flexes a little more. I don't think it's patent worthy, but thats just my opinion. Even if it could have gotten patented It is not eligible any more as the one year time frame expired years ago (assuming it was never patented). If that is the case spark fun does not owe rstraugh a cent or a few stickers! Giving him money would be like giving the person who made spoon money for every S.H.O.V.E.L. the sell. Unless you own the rights you have no clam to the $$$. That is they way the world works. Get on board or get over it!

I will be buying one soon (assuming they get them back in stock) and I hope spark fun keeps EVERY CENT!

Not even the According to Pete stickers? man you are heartless...

I was about to buy one, but the only thing that stopped me was the tube colors... they will look "ridonculous" in my bench.

I was about to buy one to but they went out of stock way faster then I expected!

@ Sparkfun PleasE get some more in stock!

I'm going to guess that SparkFun was granted permission, possibly giving a portion of the sales to rstraugh.