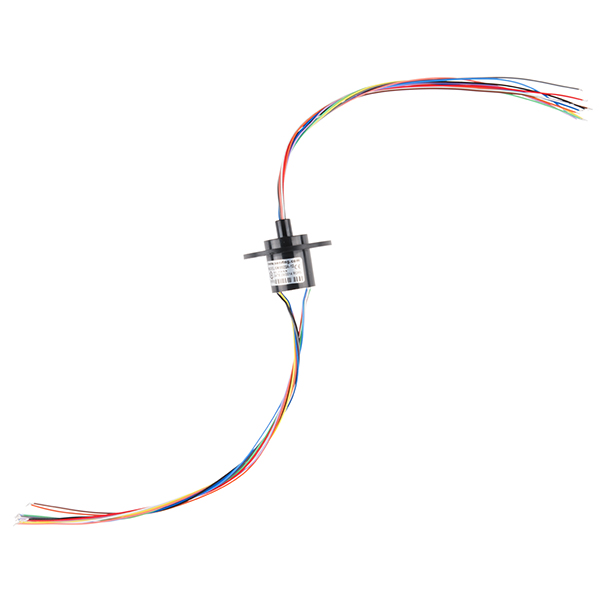

This is a 12 wire slip ring, a remarkably simple electromechanical assembly that allows electronic signals to be passed through its rotating innards. Commonly, you'd find slip rings in wind turbines, radar antennae, or anything else that requires continuous 360° rotation while maintaining an electrical connection. This particular slip ring provides you with a compact body with gold-on-gold alloy fiber brush to plated ring contacts inside.

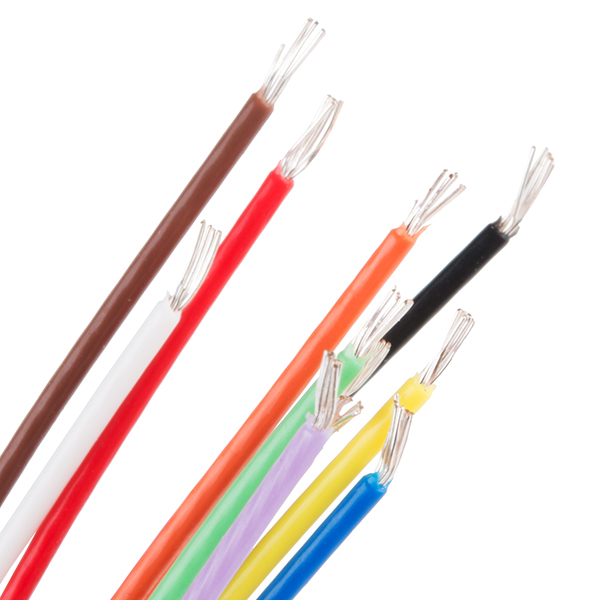

Each Slip ring is capable of handling a continuous working speed of 250RPM, a current rating of 2A, and an operating voltage of 210VDC / 240VAC. We aren't kidding about how compact this little guy is, with only and outer diameter of 22mm for the body an 44mm diameter flange, you should have no issues fitting these into your next project. Additionally, the 250mm stranded wires protruding from each side of the slip ring have a thickness of 28AWG while the whole assembly has a water protection rating of IP51.

- 12 wires

- Voltage: 210VDC / 240VAC

- Current Rating: 2A

- Operating Speed: 250RPM

- Compatible with data bus protocols

- Transfers analog and digital signals

- 22mm Diameter x 26.5mm Length w/ 44.5mm Diameter Flange

Slip Ring - 12 Wire (2A) Product Help and Resources

**Slip Ring in continuous rotation camera**

For whose who have seen the video, and want to recreate Nick's camera rig, or something like it. here is the parts list, and how they're attached. The full rig

ROB-12433 screws onto the camera mount with a bolt and washer

2x ROB-13139 1/2" standoff for USB BOB

ROB-12505 holds camera and USB BOB

2x ROB-131391/2" standoff under plate, all attached to

ROB-12209, the pulley, on

ROB-12414 clamped onto a 2" long, 1" diameter tube going through

ROB-12282, the bearing block.

ROB-13064, the slip ring fits inside the tube, with the narrow end going into

ROB-12214, which attaches to

ROB-12122, the base

ROB-12282, the bearing block mentioned before, attaches to

ROB-12287 with washers, then to

4xROB-12247 standoffs, on

ROB-12122, the base

ROB-12209, the large pulley from before connects with

ROB-12116, the smooth belt, to

ROB-12523, the hub mount pulley, which mounts on ROB-12347, the servo kit, which mounts on ROB-09347, the servo. 4x ROB-12286, standoffs attach the servo kit to ROB-12122, the base

All held together with machine screws in two lengths as needed, ROB-12525 ROB-12485

Reference Photos

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Noob - You will be required to put together a robotics kit. Necessary parts are included and steps will be easy to follow. You also might encounter basic robotics components like bearings, mounts, or other hardware and need a general idea of how it goes together.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

3 out of 5

Based on 1 ratings:

3 of 3 found this helpful:

It does what it is suppose to...

I like it, the price is right and I'm using it but I wish it was more...

-->More amperage to handle motor start/stall currents -->More shielding to prevent crosstalk between motor currents, 3.3v digital IO, and analog sensors

I used it in an antenna tracker I'm using to autonomously point a high gain yagi antenna at a flying UAV. The slip ring has to carry the signals for DC motor, hall effect sensors, i2c geolocation, i2c imu... etc. To get enough current to the motors without harming the wire or slipping I'm actually sacrificing multiple wires to carry the motor current (not ideal).

Fits nicely in an actobotics 1 in. tube.

Is there a dimensional drawing available? The drawing in the datasheet is basically pixelated to the point of being illegible.

Hi there, it sounds like you are looking for technical assistance. Please use the link in the banner above, to get started with posting a topic in our forums. Our technical support team will do their best to assist you.

I "Google" searched the product number (from the datasheet) and found this page with 3D models.

I'm new to motors and slip rings, but I have a project in mind. What is the best way to mount this slip ring? Specifically, I'm interested in using this next to this stepper motor. Can anyone provide guidance with maybe some drawings/photos of implementation?

The 2A continuous rating seems a tad high for 28 AWG- has anybody verified this?

If only this product had existed at the time I was working on this project. Similar products I could find at that time cost 10 times this price :(

I'll order one to test it... as soon as I could gather enough articles to balance the overseas shipping costs ;)

Great to see SparkFun source a product that was essential to many robotics applications (turrets, turrets, and more turrets). I have even run spi up and down these things! Don't expect to keep the motors running while communicating over those channels :).

The last time I purchased these was direct from China on EBay. Price was 3X higher. Great job SF!

Hi. Are you saying that it has to be stopped to commuicate? For uart too? Thanks.

Ive been looking for something like this for a pan tilt setup, thank you, you guys are awesome

As long as proper noise suppression is used on the drive motor(s) then communication while running should NOT be an issue.... Else, why bother with using a slip ring assembly. I have passed hi res video through slip rings (for a full color POV video display) with no noise issue and the motor was a Brushed DC motor (the noisiest kind) with proper noise suppression, (Snubber caps and resistor as well as diode back EMF adsorption)