uArm Metal - Desktop Robotic Arm

The uArm Metal is an Arduino-powered, 4-axis robot arm that has been modeled after industrial pallet packing and car building robots which can be set up and used straight off of your desktop. Each uArm is equipped with three digital servos at the base to control the basic movement of the arm and an additional mini servo attached to the end-effector that moves and rotates the object you are lifting with your chosen manipulator. We all know how much of a pain building robotic equipment can be, that's why we have made sure to provide you with fully assembled versions of this robotic arm. All you need to do to physically set it up is attach it to your desk or other work area with the four provided suction cups at the arm's base (or screw it down for more permanent uses) and you are set to start using it.

So what's all included with the uArm Metal desktop robotic arm, anyway? With each order you will receive one fully assembled metal body uArm (with servos already attached), one "uDuino" Arduino compatible board, one uArm shield, a vacuum gripper system (this includes the suction cup end-effector assembly, vacuum pump, and solenoid valve), one phillips head screwdriver for maintenance, and a USB and wall adapter power supply. While the Arduino compatible board is essentially just that, the uArm shield not only serves as a gateway to control the uArm itself it also features a "Learning Mode" that provides the means to record and replay manually assigned movement you dictated to the robot arm. Simply press the "Record" button on the uArm shield, physically move the arm as you desire, and then end the recording.

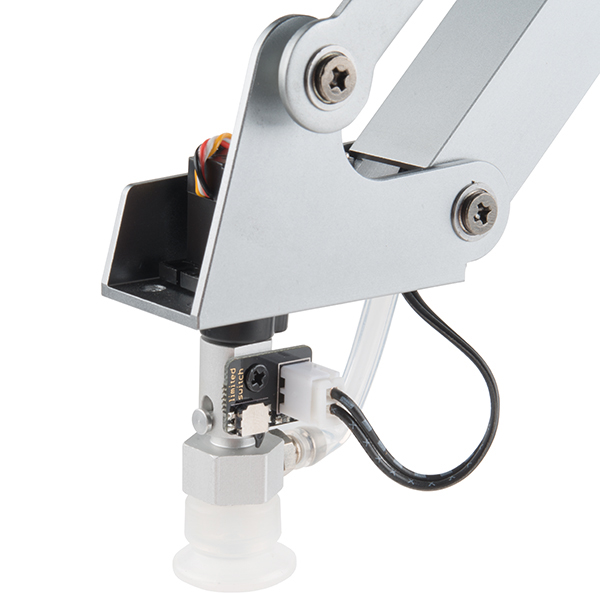

The vacuum gripper system included with the uArm Metal is driven by a 5V air vacuum pump and valve, and is capable of lifting and holding about 1 kg of weight. The end-effector suction cup can pick up most objects with a smooth exterior within the aforementioned weight limit. Since the uArm utilizes a parallel-mechanism system, the end-effector of the arm will always be kept parallel to its base. The uArm is a truly fantastic robotic arm kit that can be used in a wide variety of applications to help teach basic to advanced robotics. We've personally used it as an automatic card dealer for our merciless Go Fish tournament, but the uses for the uArm are endless.

Note: The following video utilizes the previous version of the uArm. Functionally, these two robotic arms are the same with the key difference between the two being a new chassis.

Includes

- 1x uArm Metal - Desktop Robotic Arm (fully assembled)

- 1x USB-B to USB-A Cable

- 1x Wall Adapter Power Supply

- 1x Phillips Head Screw Driver

- Fully Assembled

- 4-Axis Parallel-Mechanism

- Arm Reach: 70-340mm

- Working Range: 180°

- Vacuum Gripper System Included

- Resilient Aluminum Body

- 1kg Weight Suction Weight Limit

- Manual Record Function

- AIO Arduino based main board

- Multi-platform support(windows, linux, os X, etc)

- Improved shaft and rocker

- Getting Started Guide

- Learning Mode Instructions

- Vacuum System User Guide

- uArm Downloads Page

- GitHub (Library & Example Code)

- Product Video

uArm Metal - Desktop Robotic Arm Product Help and Resources

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4.1 out of 5

Based on 8 ratings:

1 of 1 found this helpful:

amazing

this arm has everything you need - its awesome, super easy to use and works really well - after writing your own control software.

the internal 'learning' mode sux, it never reproduces the same positions enough for any purpose whatsoever but its easy enough to program yourself.

i had to inspect the open source code to figure out the packet format for sending your own serial commands (they should really document that and provide it with explanation) -- and once this was done using my own program (in this case a python script) it was super easy to write code to do repeatable, accurate, useful movements.

I have had it doing all kinds of things like picking up rfid bingo balls and putting them in the corresponding locations, picking up and rolling dice, etc - its quite an impressive setup when combined with video tracking techniques (openCV) etc.

Awsome Robotics

I have used a number of robotic arms in various projects. The uARM is the best. It is very functional and has a nice quite vacuum system.

Nice solid arm!

It's easy to perform the final assembly. The aluminium parts are very solid and rigid. The arm worked nice with the software you can download. Smoother motion is desired, though, but the fact it's open source means this can be corrected if you want to. The suction cup proves hard to replace, but the suction power is plentiful!

good solid robotic arm

The arm is very well constructed and has powerful and precise servos. My only complaint is that issues are not well documented. To their credit, their customer service was very responsive and helped me iron out all the issues.

1) I was trying to control the arm from a python script by sending serial commands, but this wasn't working on the mac. The fix was to just connect screen to the arm (sudo screen /dev/cu.usbserial-A600CQU2 9600) and then quit screen (using ctrl-a + ). Then sending a serial command would work.

2) It's not totally obvious how to control the servo speed using serial commands. One solution is to extend the arduino code that's loaded onto the arm to add more serial commands.

Overall I'm happy that this arm has helped me do the little tasks I set out to do.

Awesome arm.

Awesome arm, and very well built, accurate, and moves fast too. Nice servos with no slop. About the best combination of price, features, and quality I was able to find.

There is some slop (say 1/4" or so at the end effector, depending on the position) in each direction but it's all in the servo spline interface to the arm hubs -- everything else is totally solid. I expected this in advance, but working on a way to possibly install small set screws, which should make it much more accurate (more than advertised) for my application.

Pretty Slick Little Robot

Ordered the uARM to join a Universal Robotics UR3 in a laboratory automation project. Lack of reliable documentation is the biggest fault of the uARM. Also, the servo cable to the wrist(?) servo was nicked and the wires were broken causing an intermittent response. Contacted the manufacturer with no response but SparkFun responded quickly and once we identified the broken cable were able to send a replacement. The uARM is now connect to the UR3 control module and working as intended.

Bad documentation

Please improve the user manual.

Hello!

Unfortunately, we actually did not write the manual for the uArm so it is not very likely that we will be able to change it. You can reach out to uFactory and see what their release time is like for an updated manual at their contact: info@ufactory.cc and they might have further information on updating the manual.

works great

software sucks. writing my own. definitely gets within 10mm as it says. overall great machine.

No code on the Github link! Not sure if they used to have some and it was deleted? Would be great if Sparkfun put together a tutorial on controlling this arm via code.

It looks like the manufacturer may be having issues with their GitHub pages. You can check out the info they have available on their site here in the mean time.

Would the uArm be compatible with the Arcade Joystick? Would the Standard Gripper Kit A-Channel Mount be compatible with the uArm, especially its servo motors?

Does the uArm come with Bluetooth capability? The uFactory website offers it, but could I purchase this feature from Sparkfun?

How difficult would it be to convert this to a 3d printer? Just take the print head off of a 3d printer and replace the vacuum head or attach the print head next to it, and then find/write code to make it extrude correctly?

Is Standard Gripper Kit A / Micro gripper Kit A compatible with uARM.

Hi i would like to know if the uArm is compatible with the Standard Gripper Kit A - Channel Mount https://www.sparkfun.com/products/13174 I would like to program the uArm to paint with a pencil in that case I supposse i also need to get the server, right? Servo - Hitec HS-422 (Standard Size) what do you recomend the Hitec HS-422 or Hitec HS-425BB thanks

I heard something about this robot arm using Analog servos. I recall these are the new generation of servo motors with direct feedback. So there's a 4th wire in the servo motor interface which provides the positional feedback back to the controller.

This obviates the need for an external position feedback mechanism on the mechanical linkage of your robot. Something I've been waiting for 40yrs now - while having to hack the servos in the meantime to perform the same function.

At the same time, this makes it much more practical in allowing you to implement the Learning Mode - less parts to deal with. You might want to emphasize the importance of this option much more than the short sentence blurb mentioned in the video, and also mention it in your Feature List -- as most people probably wouldn't notice the difference.

A version of this kit with just the unassembled arm and end effector hardware (no servos or Arduino) would be nice.

"While the Arduino com,patible board is essentially just that, "

An Extra "," in compatible