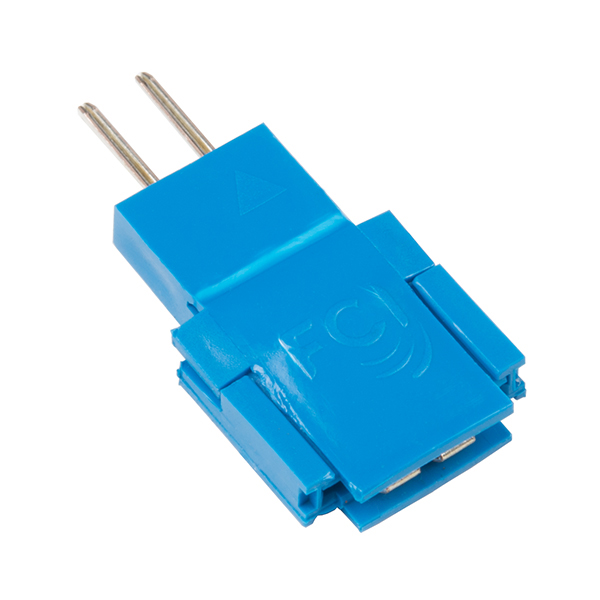

Amphenol FCI Clincher Connector (2 Position, Male)

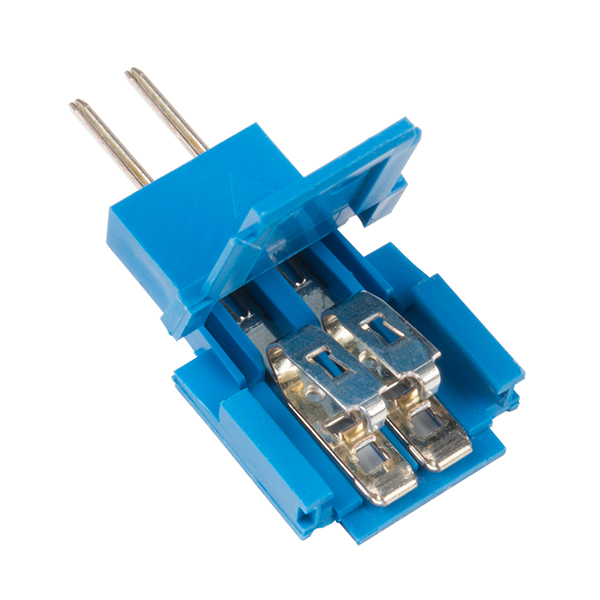

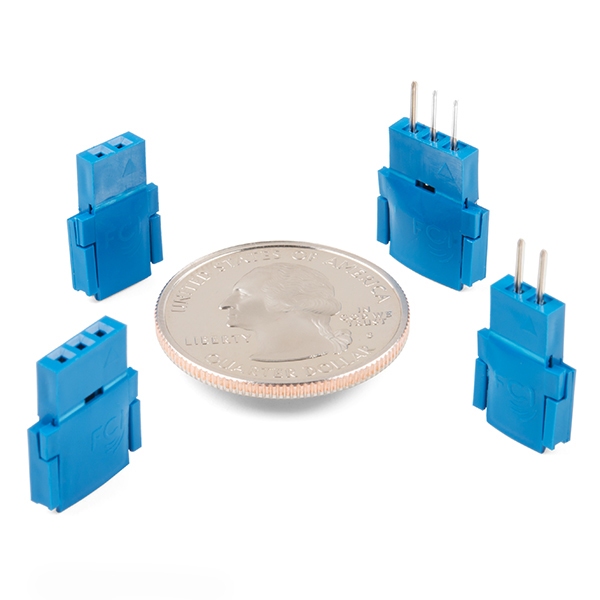

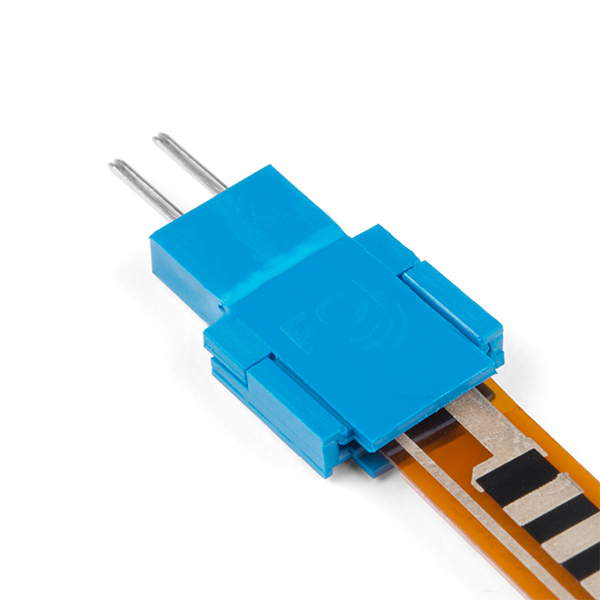

These Clincher connectors from Amphenol FCI can be used to terminate Flat Flexible Cables (FFCs) to an easy-to-use standard header. Simply insert the end of the cable into the connector and press it closed. The teeth inside the connector will "clinch" around the conductors and break them out to two male 0.1" spaced pin headers!

Though the Clincher connector can be used with FFCs, we also like to use them with our FlexiForce sensors and other flex/force sensors found in the Recommended Products section below.

Note: Please be aware that we will not be able to accept returns on this connector if it has been closed. Sorry for any inconvenience this may cause.

Amphenol FCI Clincher Connector (2 Position, Male) Product Help and Resources

Connector Basics

January 18, 2013

Connectors are a major source of confusion for people just beginning electronics. The number of different options, terms, and names of connectors can make selecting one, or finding the one you need, daunting. This article will help you get a jump on the world of connectors.

Force Sensitive Resistor Hookup Guide

May 5, 2016

How to hook a force-sensitive resistor up to an Arduino to measure pressure variances.

Flex Sensor Hookup Guide

May 5, 2016

An overview of the flex sensor - a bendable variable resistor. Plus, example circuits and Arduino code to get you started!

Core Skill: DIY

Whether it's for assembling a kit, hacking an enclosure, or creating your own parts; the DIY skill is all about knowing how to use tools and the techniques associated with them.

Skill Level: Noob - Basic assembly is required. You may need to provide your own basic tools like a screwdriver, hammer or scissors. Power tools or custom parts are not required. Instructions will be included and easy to follow. Sewing may be required, but only with included patterns.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

I agree with the others, this is garbage. But it's the only thing we have, so... bleh,

If I am understanding the previous comments, I am not sure this product is being used properly. To clarify, the purpose of this product is to clamp directly to the ribbon as the crimped pins that come on the sensors do. It can be forced to clamp to the pins already on the sensor, but that isn't what it was designed for. I hope this information helps.

Could you perhaps post a photo or a video showing the intended manner of connecting these? I too am struggling to figure out how these are supposed to fit.

I elaborated on the instructions on how to use these connectors for the FSR, flex, and SoftPot semi-conductive material if anyone needs. After figuring out how to use them, it was not too bad. There is a special tool but you can use pliers as long as you do not damage the grooves on the housing.

The product image already has a good example of a forced clamp:

Otherwise, this tutorial has a good example of a typical application:

Thanks for posting this, but no the product image provides no context that for the Flex Sensor 2.2" that you should cut off the solder pads completely. Even further, the product image and the tutorial both fail to recognize the Flex Sensor 4.5" does not have enough lead to just cut off the solder pads for this clincher to grab onto without more hackery to get it to work.

The tutorial should be updated for proper installation with a Flex Sensor 4.5" in addition to the 2.2".

I love sparkfun but is a garbage product. Overpriced and does not work well with the recommended force resistor. The pins slip out easily, the mechanism never want to close and overall is an enormous pain to use

These do not work well for clamping the pins on any of the flex/force sensors that sparkfun recommends. The pins on the sensors are way too stiff for the connector and bend out of way. This connector is really meant to penetrate the flex circuit directly. The pins attached to the sensors are already spaced correctly for header so this isn't really doing anything anyway.