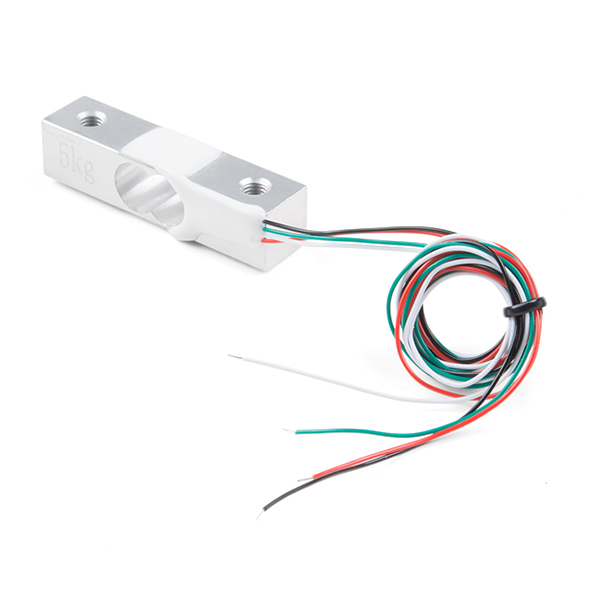

Load Cell - 5kg, Straight Bar (TAL220B)

This straight bar load cell (sometimes called a strain gauge) can translate up to 5kg of pressure (force) into an electrical signal. Each load cell is able to measure the electrical resistance that changes in response to, and proportional of, the strain (e.g. pressure or force) applied to the bar. With this gauge you will be able to tell just how heavy an object is, if an object's weight changes over time, or if you simply need to sense the presence of an object by measuring strain or load applied to a surface.

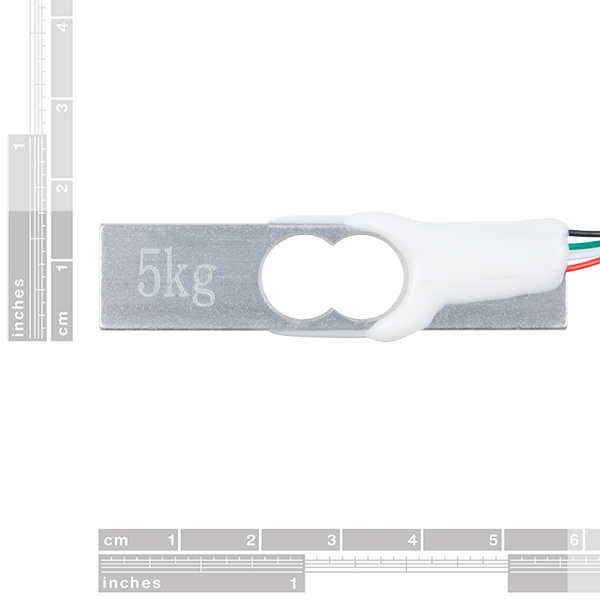

Each straight bar load cell is made from an aluminum-alloy and is capable of reading a capacity of 5kg. These load cells have four strain gauges that are hooked up in a wheatstone bridge formation. The color code on the wiring is as follows: red = Exc+, green = Sig+, black = Exc-, and white = Sig-. Additionally, these load cells offer an IP65 protection rating and features two M5 sized through-holes for mounting purposes.

- Capacity: 5kg

- Material: Aluminum-Alloy

- Parallel Beam Type

- IP65 Rating

- 55mm x 12.7mm x 12.7mm, 200mm Wire

Load Cell - 5kg, Straight Bar (TAL220B) Product Help and Resources

OpenScale Applications and Hookup Guide

July 22, 2016

OpenScale allows you to have a permanent scale for industrial and biological applications. Learn how to use the OpenScale board to read and configure load cells.

Getting Started with Load Cells

June 11, 2015

A tutorial defining what a load cell is and how to use one.

Load Cell Amplifier HX711 Breakout Hookup Guide

July 22, 2016

A hookup guide for the HX711 load cell amplifier breakout board

Qwiic Scale Hookup Guide

April 11, 2019

Create your own digital scale quickly and easily using the Qwiic Scale!

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Noob - Some basic soldering is required, but it is limited to a just a few pins, basic through-hole soldering, and couple (if any) polarized components. A basic soldering iron is all you should need.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Rookie - You may be required to know a bit more about the component, such as orientation, or how to hook it up, in addition to power requirements. You will need to understand polarized components.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

5 out of 5

Based on 1 ratings:

Load Cell, 100gm. Straight Bar, Gauge for leveling 3D printer bed.

I purchased straight bar load cells in 100gm. 500gm and 5kg ranges. I'm doing model airplane stuff, and a pair of 500gm cells is being turned into a force gauge for drag and thrust (just one axis) of an Electric Ducted Fan (EDF) in a wind tunnel -- made from a Sonatube and the suction end of a floor drying blower. But the 100gm cell is already successfully in use. I cut a U-shaped piece from aluminum strip, drilled & threaded holes to mount the load cell at the bottom of the "U" with the cell extending up the middle of the "U". Then I attached a short flat tongue of slightly thinner metal from the other end of the cell. So for bed leveling, the print head contacts the tongue and I can get matching readings at four corners, and the bed is accurately level. Then there's a separate final center-height adjustment, not using the load cell.