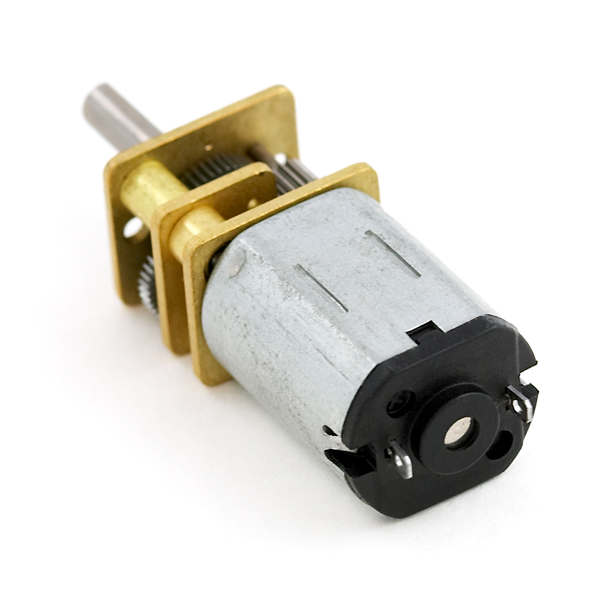

Micro Metal Gearmotor 30:1

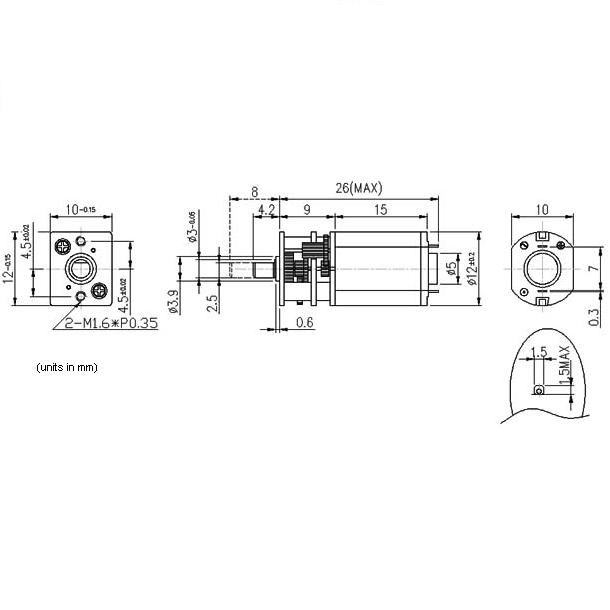

This motor from Pololu has a long (0.365" or 9.27 mm), D-shaped metal output shaft that matches the Pololu wheel 42x19mm and 32x7mm. The brass faceplate has two mounting holes threaded for M1.6 screws (1.6mm diameter, 0.35mm thread pitch), or you can use the mounting bracket or extended mounting bracket, which are specifically designed to securely mount the gearmotor while enclosing the exposed gears. We recommend the extended mounting bracket for wheels with recessed hubs, such as the Pololu wheel 42x19mm.

- 30:1 Gear ratio

- 430rpm @ 6V

- 32mA @ 6V

- 500mA stall current @ 6V

- 2.6 oz inches torque @ 6V

Micro Metal Gearmotor 30:1 Product Help and Resources

Core Skill: Robotics

This skill concerns mechanical and robotics knowledge. You may need to know how mechanical parts interact, how motors work, or how to use motor drivers and controllers.

Skill Level: Rookie - You will be required to know some basics about motors, basic motor drivers and how simple robotic motion can be accomplished.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Rookie - You may be required to know a bit more about the component, such as orientation, or how to hook it up, in addition to power requirements. You will need to understand polarized components.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

Hi, if anyone want a Eagle lib with PCB footprint for this motor, email-me. Useful for robot design.

could you send me that

can I build a balancing robot with this motors?

can i drive them with 9 volts?

For anyone who was interested, the force on this unit (at 6V) comes out to about 0.0282 Nm.

how much weight it can handle? I mean in 4wd system how much weight it can push forward?

man simply cancel inches of torque with radius of your wheel. when you have the force this is where newton comes in for m :)

This depends on a lot of other factors. The only way to figure this out is to dust off a physics book and calculate it.

i think you are right sir. but what i meant to get some info about practical values. otherwise i can do the calculations.

It provides 4 oz/in of torque. That should be enough to get the job done. I apologize if I'm missing something.

its 4 oz(in) since T=rF :)

I think the torque is off a decimal, maybe it should be 26oz.in?

If you look at the same motors with higher RPM gearboxes they all have higher torque than this motor...seems to be off an order of magnitude.

Id like to know if any of the swivel clamps will fit this motor. On the recommended products section there is only one mount for it. Is there another one provided by sparkfun that will fit? Thanks

is the 430 rpm for the motor or for the shaft after the gearbox?

Are those gears metal?

I wouldn't call that a long shaft. I need at least 1" long to mount wheels directly.

I have a 6V, 300 ma power supply. What would happen if I used this, compared to a 6 (or 5) V, 1000 ma power supply for this motor?

The motor draws as much current as it needs. When it stalls out, it draws its max. It's max current draw is 360mA.

Does anyone have any experience with feedback of this motor? What is the backlash like in the output shaft (how many deg can you wiggle the shaft w/o turning the motor)? Is there space enough to get a hall effect (sparkfun variety in there for gear tooth counting?)

Has anyone tried swapping out the motor, and using the gearbox with another motor? Is that possible? I'm not sure how they are connected or what the diameter of the motor shaft is (Not the D-shaped shaft, but the shaft coming directly out of the motor itself)

How would I find the speed of these motors? km/h. using the 32x7mm wheels. Which the voltage is being controlled by PWM on the arduino.

Sure, with a 32 mm wheel, 32 X Pi = 100 mm. 100 mm X 440 rpm = 44000 mm per minute, or 44 meters per minute, or 2640 meters per second, or 2.640 km/h.

sorry, second to last i meant, 2640 meters per hour.

How can I control this motor with an Audrino, if I wanted to connect it to a analog pin?

You will need to use a motor controller like this or a motor driver like this.