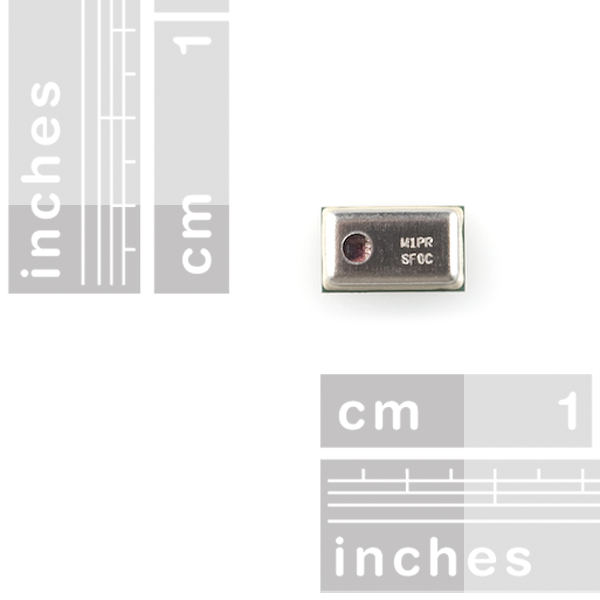

The MPL115A1 is a digital barometer that uses MEMs technology to give accurate pressure measurements between 50kPa and 115kPa. We stock the SPI interface version of the sensor. Average current consumption is 10µA at one measurement per second.

The sensor outputs both temperature and pressure readings on the SPI bus. See page 3 of the datasheet for information on how to take readings from the pressure sensor.

Breakout board coming soon!

- Wide supply voltage range

- -40°C to 105°C maximum temperature range

- Low power consumption

- Monotonic pressure and temperature data outputs

- kPa accuracy* 5 x 3 mm (1.2mm height)

Barometric Pressure Sensor - MPL115A1 Product Help and Resources

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

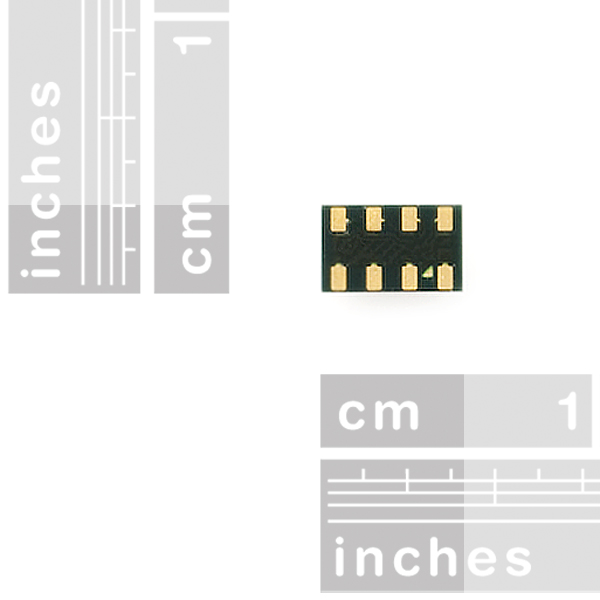

Skill Level: Competent - You will encounter surface mount components and basic SMD soldering techniques are required.

See all skill levels

Core Skill: Programming

If a board needs code or communicates somehow, you're going to need to know how to program or interface with it. The programming skill is all about communication and code.

Skill Level: Competent - The toolchain for programming is a bit more complex and will examples may not be explicitly provided for you. You will be required to have a fundamental knowledge of programming and be required to provide your own code. You may need to modify existing libraries or code to work with your specific hardware. Sensor and hardware interfaces will be SPI or I2C.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

The datasheet says the average current consumed is only 5 µA at 1 reading per second, but the description says 10 µA- is your description based on testing done by SparkFun, or is this just a typo. I mean, 5 µA between friends is nominal, but I'm pinching electrons for a project right now and was wondering.

I too would be interested in solder suggestions for this sensor. I have successfully soldered the part using a heat gun (not recommended according to the data sheet). The returned pressure is a bit lower than I would have expected, but not completely unreasonable. I also used flux (before soldering) and 99% isopropyl to wash the board (after soldering). I attempted to avoid completely submerging the part in the isopropyl, but I am unsure if this could cause problems. Do you guys have any thoughts on that?

Hi Sparkfun, I'm curious what your experience with the reflow soldering of this sensor is. According to the datasheet one should have an inert reflow environment. Do you think this is really necessary? I only have a converted-pizza-oven type of reflow at hand... Thanks, Sukandar

I bought two to play with as there is still no breakout board??? Been coming for 4 years!!

You mean this breakout board?

Damn! couldnt find that

roybean VFR Aircraft altimeters are usually accurate to within a few hundred feet. The digital ones usually have one like this for higher altitudes as most standard barometers work up to 4k feet or so. So the +/- 400 feet doesn't surprise me on this.

The FAA regs uses an even/odd altitude depending on direction +500 feet (this + 500 feet is there to allow for inadequacies in instruments).

GPS altitude is usually much more accurate, but since in aviation everyone should be using pressure settings from fixed stations and planes move around the altimeter isn't adjusted constantly the altitude is wrong but its usually wrong for everyone, sometimes the GPS accuracy can cause issues it that is what you are going by.

However on landing you use ILS or other ground based electronics to fix altitude to within a few feet.

roybean you are correct which is a bit odd, obviously this varies but roughly the resolution is 40ft or thereabouts yet the possible error on this value is in the region of 280ft, you might get a good unit reading 0ft at sea level or a dodgy one reading ±280ft

looks like this sensor has an accuracy of 1kPa. According to altitude charts, this could result of an error of 400 feet. seems like a lot to me, but the datasheet says this sensor is used for altimeters.

Maybe I am misunderstanding the accuracy spec?

The Freescale eval board for this is the best deal on the planet -- $15. The part also comes in an I2C version, as does the Eval board.

http://www.futureelectronics.com/en/technologies/development-tools/analog-power/Pages/8762254-KITMPL115A1SPI.aspx

Check Freescale's own website for other potential distributors of the eval board. They also have a higher-priced dev board that you can connect right to a PC.

They also have a demo video somewhere that I saw almost a year ago of one of the team members walking up some stairs with it showing the altitude change. Very cool.

Looks like a great sensor for my greenhouse/cellar-house automation application. Waiting for the breakout board!