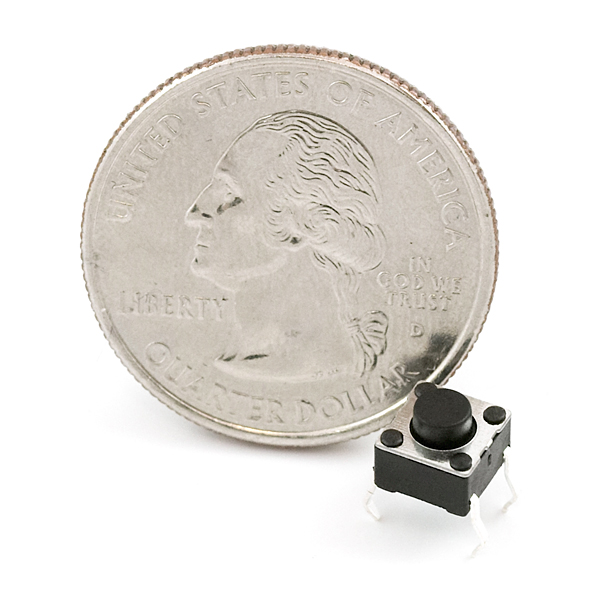

We use these little buttons on everything! These Miniature Single Pole Single Throw switches have a good click to them and are breadboard friendly. Perfect as a tactile reset switch. These momentary buttons are rated up to 50mA.

Mini Pushbutton Switch Product Help and Resources

IR Communication

February 7, 2013

This tutorial explains how common infrared (IR) communication works, as well as shows you how to set up a simple IR transmitter and receiver with an Arduino.

Button and Switch Basics

May 7, 2013

A tutorial on electronics' most overlooked and underappreciated component: the switch! Here we explain the difference between momentary and maintained switches and what all those acronyms (NO, NC, SPDT, SPST, ...) stand for.

Beginner Parts Kit Identification Guide

March 22, 2019

The essential parts for beginning (or even experienced) hobbyists that gives you all of the basic through-hole components you will need to get started playing with embedded projects. We'll identify a few parts in the kit and provide a few basic circuits to get started!

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Noob - Some basic soldering is required, but it is limited to a just a few pins, basic through-hole soldering, and couple (if any) polarized components. A basic soldering iron is all you should need.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Noob - You don't need to reference a datasheet, but you will need to know basic power requirements.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4.7 out of 5

Based on 3 ratings:

3 of 3 found this helpful:

The remote on my gas log unit suddenly refused to turn the unit off. Some trouble-shooting revealed that the "off" circuit pushbutton was broken. Went up on the internet looking for replacement remotes. $94.00 plus S&H. Went up on the internet looking for pushbutton switches. Found you, then found the switch, with enough specs to assure me that it was the switch I needed. 35 cents plus S&H. Bought it, installed it, remote's good as new. That's a triumph in my book. I'll keep you in mind in case I have to rebuild my TV.

1 of 1 found this helpful:

4 pin buttons

I love these 4 pin buttons. I can put them on my breadboard and the feeling when I press the switch is perfect. I recommend this product.

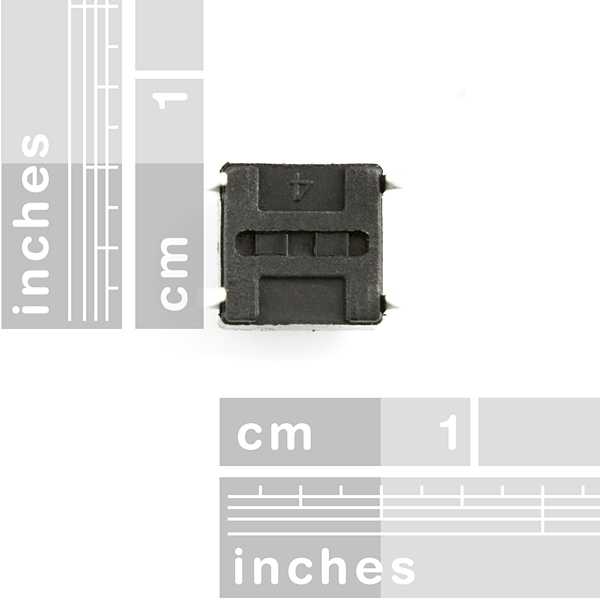

Good Button, unexpected poles

I had expected the two pins that were on the same side face of the button to be the pair for each pole; however, the paired pins for each pole are on opposing faces of the button. Otherwise, button is fine.

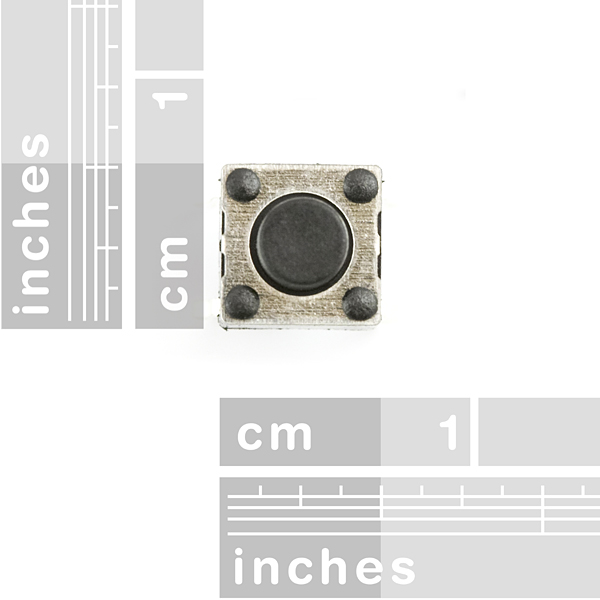

What size is this? 6x6x5?

The pins are too short to be used with a breadboard.

I have two of these on a breadboard right now. Maybe it's your breadboard.

they're just barely long enough to fit in my breadboard. I have 3 different breadboards and all the switches fit the same. They do work but also fall out with the slightest bump on the board.

That is just the nature with this type of switch. They aren't designed to be breadboard freindly, they are designed to fit on a PCB. you will see these switches in a lot of common household electronics. Take a pair of needle nose pliers and bend the leads so they are closer/farther away. this can help 'hook' the button in place so it wont fall out.

GUYS! I've discovered an excellent technique for making these types od buttons breadboard friendly. First, using pliers, remove the kinks from the legs, making them straight pieces of metal flush with the sides of the button. Next, grab the middle of a leg with the pliers and twist 90 degrees.

!!!

SF, please add this to the description. A 90 degree leg twist... who'd have thought?

That makes so much sense. My life has been changed.

When I first read other people reply, I though they were all sarcastic, and that it was maybe a stupid idea. But at 90 cents for 20 push buttons, I though I could risk 4 cents over a possible solution to an extremely annoying problem. So I took a new button, straiten the pin, and twisted them 90 degrees:

Wow ! The button is not "clipped" in the bread board, but it doesn't tend to pop out anymore, and it improved the situation by at least 90%. That's a very smart advise.

Big thank you Member #183815 !

Its about time someone came up with a solution for this. I've straightened out the legs before, but never would I have thought to twist them.

You are a genius.

I had the same results

If you straighten the pins with a pair of needle-nose pliers, they fit perfectly into a breadboard

I tried this and it was still not staying in. In fact, I've had a few actually jump off the board. I ended up tinning each leg with a bit of solder - that seems to work well.

If you're in the Dallas area, Tanner Electronics has these exact same buttons for 15?.

This product made me a hero.

The left button on my wife's laptop had given out and was failing to register a press about 25% of the time. The culprit was a button just like this except in SMT gullwing form, soldered to the motherboard. I happened to have one of these sitting around (which I didn't even know... the wife found it while digging through my spare parts). I straightened and bent out the legs with a pair of needlenose pliers and snipped them down, and it was a perfect replacement.

Lesson learned: you can never have too many spare parts. (Alternate lesson: I could really use a hot-air rework station. My desolder-fu is weak.)

What I mean is: does the button stay closed when you release and require a second push to change the state back? I don't want a momentary push button.

This is a momentary push button. :( We do have a board that turns a momentary button into push on / push off if that is helpful: https://www.sparkfun.com/products/8903

The dimensional drawing shows the 7mm tall button, but the picture is of the 5mm one, and one comment states that these are the B3F-1000 ones, the 4.3mm ones.

From the omron b3f datasheet, the only ones with a black plunger is the 0.98N push force, 5mm tall ones. These are the ones I need, and I'm assuming the picture, taken by you guys, is of the ones you have. (already ordered some, hoping they're right... if not, I can still work around it)

Confirmation on this? Maybe the description should be more specific, and the dimensional drawing/pictures corrected?

Also, a random B3F omron switch that I found in a drawer of random electronics things has on the bottom a label "OMRON" and "B3F" The button pictured here doesn't have these, and also appears to be made of a cheaper plastic then the one I have (a little fuzzy around the corners)

Are these actually the b3f-1020 switches?

Okay, I don't believe these are really B3F switches.

As I said, a genuine B3F-1000 switch that I have is marked "OMRON" and "B3F". It is the 4.3mm variety (I needed a bunch of the 5mm tall ones), with an ivory plunger, which signifies it's the 0.98N force switch. Confirmed from here: http://www.omron.com/ecb/products/pdf/en-b3f.pdf

According to that same datasheet, the ONLY B3F switches that have a black plunger like the switches on this page are also 0.98N activation force.

The switches sold here take very considerably more force to press, even more than some other generic 5mm tall black-plunger tact switches that I have. These switches, although they appear to at least be made of higher quality than the ones pictured, also still don't have the "OMRON" and "B3F" labels.

It's really disappointing, I bought these for the low activation force, which these switches here definitely don't have. (and also for the 1million cycle rating, which who knows what these switches are rated for)

Fantastic little buttons, im always running out, great for reset buttons and to be used for digital inputs either pullup or pulldown

are these normally open or normally closed?

The legs bending towards each other are normally closed, when you press the button all sides are closed if i remember right

If i want buttons in my finished project can i use these?? Can you have a tutorial about something like panel mount buttons???

Does this push button switch have two settings, ei: pressed completes the circuit and when pressed again it's not?

Is this the smallest on-off switch you have by chance?

I've got 2 different breadboards and whoever said these "fit" has obviously never tried it.

They fit for me on both of my two breadboards.

They do fit. Are you putting it across the center(the gap)?

I bought 3 of these switches and none of them work. They are always on and when I push the button they read 0 v.

Contact techsupport at sparkfun dot com and we can get you taken care of

I just hot glued them to my board. It does not take much to hold them in and they pop off with enough pressure.

Fits perfectly in a breadboard.

lol? Ok then, They fit in a 0.1 inch spaced breadboard(aka the standard breadboard :) i have your breadboard from here and 2 from parallax and a small one from here too and they fit perfectly the way i use them. I don't put them in the center.)

Well if they don't work for you, try to get a RMA number and try to return them.

Are you and JAA some kinda spambots who have been set to say "These won't work with a breadboard, Booohoohoo!" no matter how many fixes people give that might work? I mean, do you even TRY the fixes before saying they don't work? 'cause this one seems to have positive feedback:

Member183815 said:

"You find it funny that these do not work as advertised for me?" Advertised? lol? He finds it funny that you're making such a pointless repeat fuss about this. IT'S 35 CENTS!! It's not like you bought a computer from here and it broke in 3 days!

then /me said:

They may fit perfectly in YOUR breadboard but that does not mean the fit in EVERY breadboard.

Stop griping about it. Just return it, find one that works, and quiet down. Usually people just do that in the first place instead of filling up th' whole frickin' comment section with pointless flaming and web arguments.

I found this to be the case also... although the pins may be spaced at .1 inches on all breadboards, this doesn't mean that it'll fit and stay in nicely in all. The spring contacts may be of different tension on different breadboards, and the plastic layer between the parts and the spring contacts may be of different thickness, changing the way the legs fit. I know firsthand that they work in some, but not all breadboards, because these DO NOT stay in my mini breadboards sold here at Sparkfun, but they DO stay in my Radioshack breadboard. I like these switches, they work nice on perf boards and certain breadboards.

I have a radioshack breadboard so it will work with mine yaaaaaaaaaaaaaaaaaayyyy!!!!

Bought dozens of these for a breadboard project. Was disappointed to find that the pins are too short, and it doesn't seat well in the breadboard - while it'd kindof work, they'd fall out regularly.

At the same time, the long push button, (COM-08986) worked really well. I'll be buying those in the future. Tiny variation, huge difference in how it fits in the board.

Just bend the pins a little inward and they fit perfectly.

They DO NOT stay in this breadboard...

http://www.sparkfun.com/commerce/product_info.php?products_id=112

Straightening the pins DOES NOT MAKE A DIFFERENCE.

The ones sold by Parallax are the same price, are large enough to stradle the center divide, and fit perfectly in a breadboard.

I don't use them in the divider

NOBODY CARES!!!!! I am talking about JAA2 not you Matt. =)

Good switches - nice height, sturdy feel

I have ordered a bunch of this push buttons. These push buttons fit easily into a breadboard. However, now that I have my prototype working and I am making a schematic in Eagle, I have no idea what the dimensions are to make my switch component in Eagle. It is very frustrating and time wasting.

This switch is actually in our Eagle libraries. Check under the Electromagnetic/Switch-Momentary-2 section. It should be the first one (Description: Omron switch). Or internal part number is SWCH-8441, as long as you have that one selected you should be good. Feel free to email techsupport if you have any other questions or ever need more information.

Hi everyone from western Australia .Question i have a car imobolizer that has these switches ,im not sure as to the correct one to use, where would i look on circuit board to tell what type to use. the one in pic here looks the same ,im not to sure on ohms , Your feed back would greatly be appreciated .Kind regards David

Thought this might help: If these are falling out of your breadboard and messing you up, put a small glob of hot glue on the bottom before putting them on. They won't be able to fall off, and if you need to get them off, the hot glue will peel off with ease.

Is this a momentary contact switch or does it latch in the on state and the next time depressed if latches in the off state?

Does anyone know where to get rubber baby buggy bumpers - i.e. the little rubber covers for these things? I would like a nice button to be flush with the surface of the box for my projects, but these seem to be custom, spend $5K in tooling sort of things out there. I would think that they should be a commodity type of item!

Is this a normally open or closed switch?

normally open

Are these on/off type toggle switches? If not, do you have any of similar size?

No they are not toggle switches. They just are momentary, so they do not stay in that position if you release.

If you are looking for a similar size, a spdt switch might work well https://www.sparkfun.com/products/9609

Or if you want an actual toggle switch (which will always be around this size which is a little bigger) this is a good quality one. https://www.sparkfun.com/products/9276

way too difficult a website

I was wondering if anyone knew where to find the data sheet for this part. Any help is appreciated

http://octopart.com/info/Omron/B3F-1000

There's a datasheet + all the pertinent info there.

You can get these from Mouser too, Mouser part # 653-B3F-1000

Mouser doesn't normally stock 653-B3F-1000 any more. However you can get a similar Mouser part 642-MJTP1230 for $.07 each; it's the same except that it has a shorter (i.e. flush) button.

That was my first mouser purchase. 10 buttons

Why buttons?

You can get a similiar part for only $.05, 653-B3F-4000, at http://componentsearch.com/search/searchResults?keyword=653-B3F

for 22 cents, no minimums

Hi,

I also have problems getting them stay in the 830-pin Pololu breadboards (http://www.pololu.com/catalog/product/352)

They do fit fine the wrong way around (ie the flat sides of the pins parallel to the connected lines), but then they're useless since they're always on...

Would be ok across the divide, but the divide is too wide (4 steps)

My solution: straighten the pins (not enough on it's own as noted by others), then rough them up by plating them with solder

HTH, Jonathan

Nice little buttons. They do fit well in the mini ( railless ) breadboards they sell here, but I can't get em to fit in any of my Elenco or Archer (Tandy) boards.