×

SparkFun will be closed on Tuesday, December 24th, and Wednesday, December 25th, in observance of the Christmas holiday. Any orders qualifying for same day shipping placed after 2:00 p.m. (MST) on Monday, December 23rd, will be processed on Thursday, December 26th, when we return to regular business hours. Wishing you a safe and happy holiday from all of us at SparkFun!

Please note - we will not be available for Local Pick up orders from December 24th-December 27th. If you place an order for Local Pick-Up we will have those ready on Monday, December 30th.

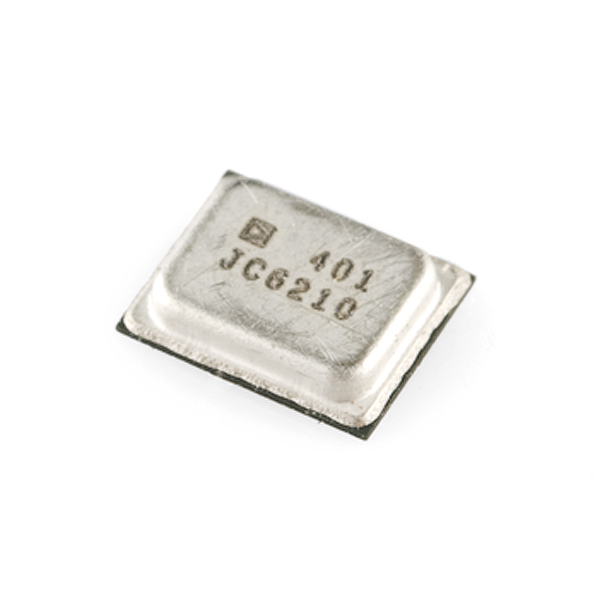

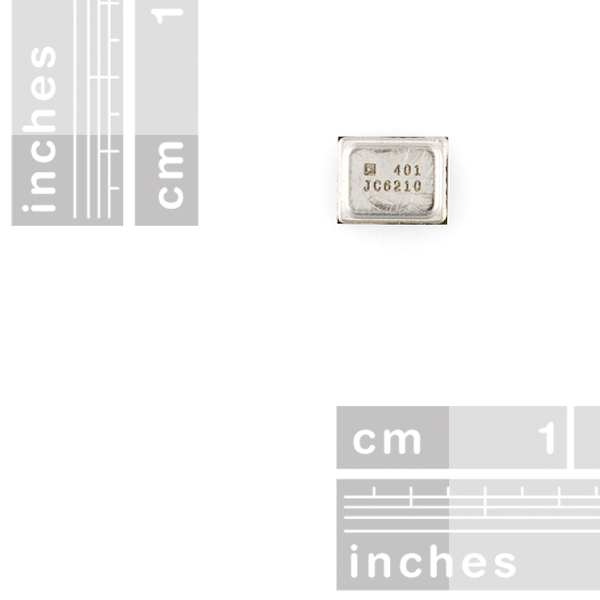

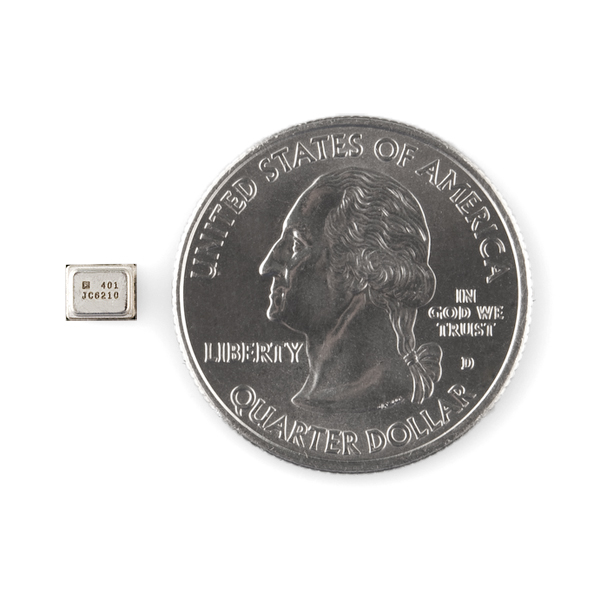

MEMS Microphone - INMP401 (ADMP401)

The ADMP401 is a high quality, low cost analog output bottom ported omnidirectional MEMS microphone. That was a mouthful! A wide frequency response and low current consumption makes it perfect for embedded applications. Check for a breakout board below.

- Sensitivity of -42 dBV

- Low current consumption of <250 uA

- Single-ended analog output

- Flat frequency response from 100 Hz to 15 kHz

MEMS Microphone - INMP401 (ADMP401) Product Help and Resources

MEMS Microphone Hookup Guide

January 27, 2017

Get started with the SparkFun analog MEMS microphone breakout board with Arduino! Create a volume unit meter with the ADMP401 or ICS-40180 to react to sound before building your sound visualizer!

Bark Back Interactive Pet Monitor

March 8, 2017

Monitor and interact with pets through this dog bark detector project based on the Raspberry Pi!

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Competent - You will encounter surface mount components and basic SMD soldering techniques are required.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

LMFAO!

"We are working on a breakout board and will have it available shortly after you actually needed it."

Score one for honest businesses haha. You guys are great.

I have used many different small speakers to record sound. Has anyone used this mic as a tiny speaker (ear bud or within the ear) or know if it would work?

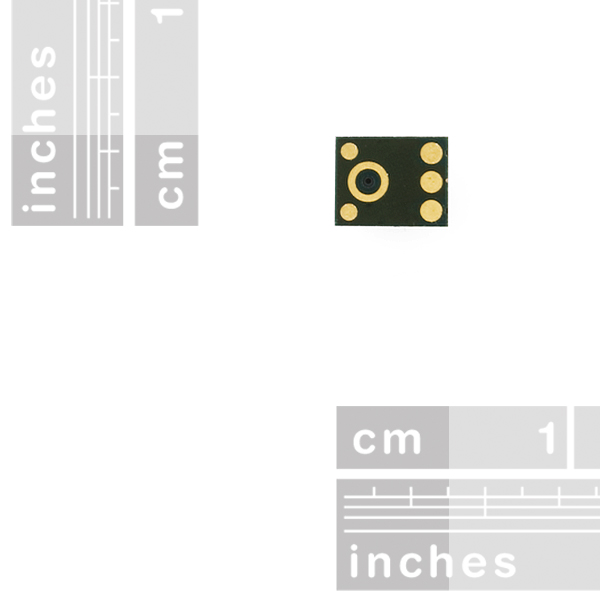

For what reasons is there a hole at the bottom. Do we need to connect that to ground. No such ground connection shown for the breakout board.

check out page 5 and 6 of the datasheet.

Confirmed by the pictures, it is the same size no matter witch way you flip it. :)

sir i require an MEMS sensor how can i get it

Wonder if this would be suitable for a bat listener? the small size of the MEMS should make it ideal methinks.

-A

What is the best way to solder it?

Magic fairies that crawl under it and explode to heat up the pads.

add a via in the footprint, heat it from the other side of the PCB with the soldering iron.