Flow Meter Kit - Small

Replacement: None. We are no longer carrying this Flow Meter Kit in our catalog. This page is for reference only.

Atlas Scientific is on a mission to make high-quality sensors for environmental monitoring available to everyday hackers and makers. All of their kits are easy to calibrate and connect to your microcontroller-based project.

Sometimes in life you have to just go with the flow... and sometimes you have to meticulously measure the rate of said flow. For those latter situations, Atlas Scientific has put together the Small Flow Meter Kit. This kit includes everything you need to set up a lab-grade embedded flow meter system accurate to ± 1mL/min.

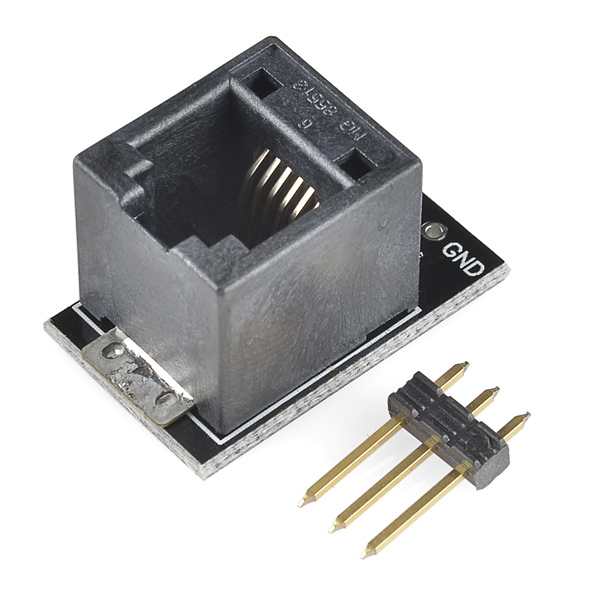

Along with a TurboFlow-22600 flow meter, capable of measuring rates from 800 ml/min to 7.6 LPM, the Small Flow Meter Kit also comes with a 178 micron stainless-steel mesh pre-filter to protect your meter from instrument-clogging sediment. Simply install the filter and flow meter in-line using threaded pipe-fittings then connect the extended flow meter cable to your embedded controller using the included RJ-11 breakout and FLO-30 flow meter circuit.

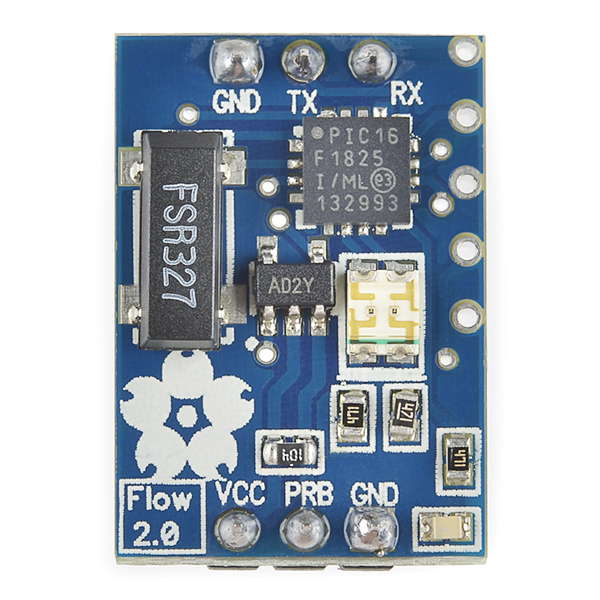

The FLO-30 flow meter circuit outputs simple comma separated values over RS-232. The output string is easily readable: 3 values ending with a carriage return. Each reading gives you the total liters, liters per minute and liters per hour. These meters are great for everything from hydroponic gardening to water conservation.

- FLO-30 Flow Meter Circuit

- TurboFlow-22600 800 ml/min to 7.6 LPM (accuracy ±1 lm)

- Extended flow meter cable to 1M (3.2 ft) with male RJ-11 connector

- Female RJ-11 connector breakout board

- 178 micron stainless steel mesh pre-filter

- FLO-30 Circuit decal

- Scientific grade results

- Calculates total volume flow, L/minute, L/hour

- Enable/disable flow meter

- Flow indicator LED blinks with each turn of the flow meter

- Built in total volume flow alarm

- Cable length >10 meters from circuit to flow meter supported

- Single reading or continuous reading modes

- Simple RS-232 connectivity (voltage swing 0-VCC)

- Simple instruction set consisting of only 12 commands

- Debugging LEDs

- 2.5V to 5.5V operational voltage

- Meter Material: Glass Reinforced PPO (Noryl)

- 9.5 mm (3/8") male threaded fittings

- Operational temperature: -20°C (-4°F) to 80°C (176°F)

- Max operational pressure: 1,378.95 kPa (200 psi)

- Food Safe

- Gasoline Safe

- Diesel Safe

- Kerosene Safe

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

Just had a look at the Atlas Scientific web site. They have some neat stuff!

Does anyone know if this will be ok in Salt water for marine tank?

Hi folks! I need a very low flow sensor to be able to detect microleaks(some drops maybe) in a ~3" tube or bigger. Is this possible?

You need better definition of your application here - there's not enough to go on. What pressure? 3" diameter, or length? What type of liquid? What material is your pressure vessel made of? Depending on the design of your application, it MAY be easier to detect integrity problems at low pressure than at system or even proof pressures. Also, is this a single test, or is it a production / acceptance test? I am a retired aerospace engineer, with extensive test equipment and fluid power design experience. I'd be glad to help, if it keeps my damaged brain busy....

I've got a similar need, and I'd be very curious to hear any suggestions you can come up with! I'm trying to measure low flow rates (say, less than 1 mL/min to 30 ml/min) at atmospheric pressure (very very low pressure differential), with minimal disturbance of the flow. I'm hoping to find a flowmeter with a diameter 1 cm or greater, but diameter and flow sensitivity appear to be inversely proportional, so most of what I've seen is in the 1 mm range.

This is the best sensor I've found, and it appears to be possible to control with an Arduino: http://www.sensirion.com/en/products/liquid-flow-sensors/components-for-oem-applications/lg-flow-sensor/

I haven't found any other sensors that appear to reach such low flow rates (I've looked into ultrasonic, electromagnetic, and heat-pulse types). Any thoughts?

Turbine flowmeters typically have a 10:1 turdown accuracy. With good bearings and more precise machining, 50:1 is reasonably attainable. A high - priced RF pickoff can eliminate magnetic reluctance on the turbine, and get you to 100:1. Factors such as viscosity, density, and air entrainment (for liquids) also effect accuracy. Only a positive - displacement flowmeter is truly accurate, but with that comes pressure drop and cost issues. $130 is pretty reasonable for a turbine and conditioning circuitry.

All I want this thing to do is tell me how much beer is left in my keg. Inspired by the Sparkfun Tweeting Kegerator? You bet!

I'm having a bit of trouble getting the sensor to read a value. I can poll the board with serial commands fine. Troubleshooting LEDs for serial commands flashes correctly. However, when I plug the sensor in, with water flowing through the meter, I don't get any reading...remains all zeros for the response for "R" command. The troubleshooting LED for each pulse of the meter does not flash either as if the sensor is not working... Any ideas?

Fixed. Found a few problems...I unsoldered the header pins which might have been the cause. Found out the sensor was working correctly by looking at the signal using a scope. Eventually tracked the problem down to the sensor pin on the board being shorted to ground. Cutting the trace from the 10K pullup resistor to the sensor pin on the board and soldering a tiny wire to the end of the resistor to the sensor wire did the trick. Also note if you're not using the breakout board, like I am, double check the pin trace to make sure that each wire in the RJ11 connector is going to the right wire in your project. Found out the following color codes for the wires in the RJ11 connector: RED=VCC, Black=GND, Green=Signal.

Guys, 0 - VCC is not a valid RS-232 serial level. If you connected this to a proper RS-232 port, it would not work. Please correct this in the spec as it is misleading and some people would take it to mean you can connect it to a PC or something similar directly.

RS-232 specifies that the voltage must swing between a negative voltage and a positive voltage to represent logical 0's and 1's. The minimum swing normally accepted for this is from -5V to +5v with anything in between being ignored (i.e. 0V).

Just thought to mention that RS-232 doesn't just specify the voltage swing, it also specifies a specific protocol including mark, start, and stop bits used to interpret the information.

My interpretation is that it both does and does not meet the spec. Saying it's RS-232 is much easier than trying to describe the serial protocol with the exception of the voltages, imo.

Just because it's not valid doesn't mean it won't work - most RS-232 hardware inside modern laptops can handle Vcc level swings just fine, as long as the baud rate isn't extremely high.

Just because the spec says something doesn't mean the way they build the hardware to handle the spec will only do what the spec says.

Most modern laptops don't have RS-232 ports, so that's kind of a moot point.

Whether or not the serial port accepts those levels is another question, and probably stems more from people watering down the spec by doing crap like this.

I'm not saying it 100% won't work, but referring to it as RS-232 versus TTL will just confuse the issue, and also leads to the possibility of damaging the device.

http://www.sparkfun.com/tutorials/215

Can this be used for air flow as well?

Wonder if this will work in my kegerator project... I hate when i find out my kegs are empty...

I sent an email to Atlas's tech support center. CHEER! they said: "The flow meters we use are both food and chemical safe. They are actually used in automated beverage dispensing machines by..."

He later follows up with, "We use them here a lot for all kinds of chemicals."

It would be nice if they specified what products the flow meter is compatible with.

Is this only good for water? What about hydrocarbons, like gasoline or diesel?

Check out the product page on Atlas' website

It only describes what the flow meters are made of, not what liquids they are compatible with. I supposed one could assume that if a material is compatible with a liquid, the meter is as well, but we all know what happens when we assume.

You're usually right?

After reading more, I assume that the flow meter has to be rated for hydrocarbons, because they can degrade some types of rubber and plastics.

I bought a $9 flow meter from Seedstudio (name?) that only needed a couple resisters to work with the Arduino. It currently measures out the appropriate amount of water into the coffee pot each morning via a 12 digit keypad. $130 seems a lot, but it must do a lot more?

this one's actually accurate in a laboratory setting and can be used for accurately measuring flow for mixing chemicals and such.

Did they say whether this flow meter is food grade? Like if I wished to use it to measure the amount of beer flowing out of my keg, would this be usable without putting off flavors in the beer?

Id be more concerned with foaming the hell out of your beer. I'm a homebrewer. For a good pour, you need very smooth tubing with very little interference to the flow. Putting this turbine-type meter in line with your dispensing system may foam your beer up terribly. Might not - but - I dunno, I'd worry about that.

We really ought to do some testing.

So like for making the perfect martini. :-)

exactly!

I don't think 1 ml is particularly accurate. Especially if the low end of the sensor is really 800ml/min. For 1/10th the cost you can get something 2.5 ml accuracy. http://www.adafruit.com/products/828

I might be wrong here, but it says each pulse is equal to 2.25ml. so that means you can only read in increments of 2.25ml, which does not mean 2.25ml accuracy.