×

SparkFun will be closed on Tuesday, December 24th, and Wednesday, December 25th, in observance of the Christmas holiday. Any orders qualifying for same day shipping placed after 2:00 p.m. (MST) on Monday, December 23rd, will be processed on Thursday, December 26th, when we return to regular business hours. Wishing you a safe and happy holiday from all of us at SparkFun!

Please note - we will not be available for Local Pick up orders from December 24th-December 27th. If you place an order for Local Pick-Up we will have those ready on Monday, December 30th.

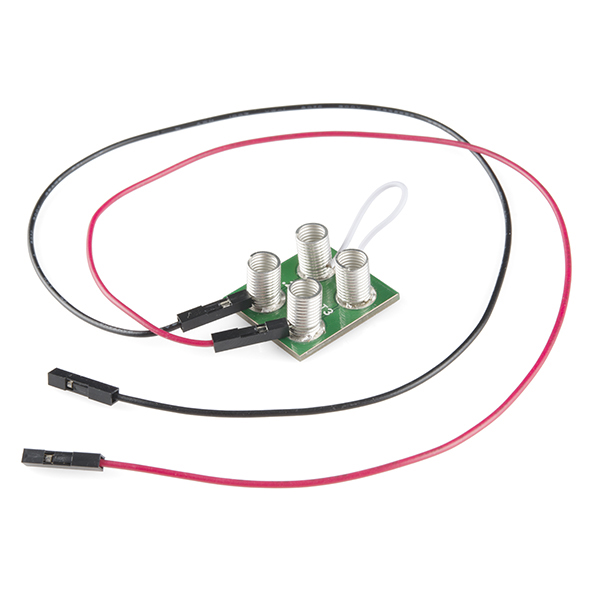

Spring Connectors (pack of 10)

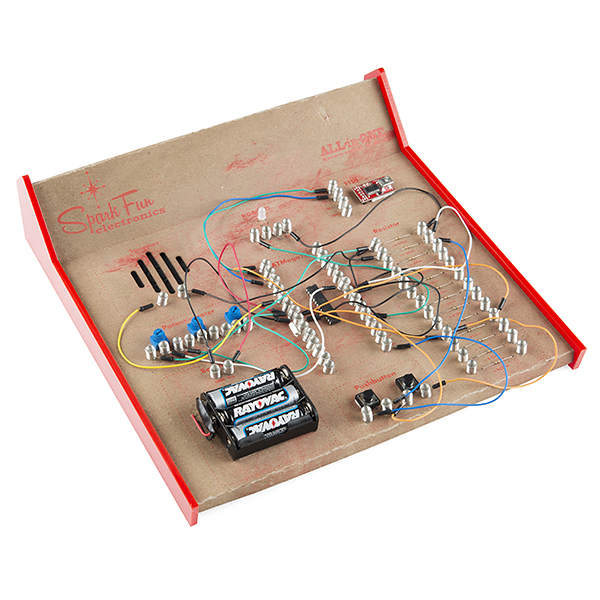

If these spring connectors look familiar to you, they should. They have been used in a multitude of beginner electronic labs teaching the basics of circuitry and electronics. All you would have to do is push the spring back and insert a wire lead in between to coils, and voilà, you have made a solderless connection. We remember how easily these spring connectors were to use when we first handled them, so why not incorporate them into a project now?

We are offering these steel spring connectors in packs of ten with each end ground flat to make soldering easier for you. These can even be used on protoboards with 0.1" spacing, by using a grid of 9 holes (check the video below).

Note: The board that you see in the photos to the left can be found under the name "SPRING-CONN" in our Eagle Library.

- 0.25x0.35"

Spring Connectors (pack of 10) Product Help and Resources

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Competent - You will encounter surface mount components and basic SMD soldering techniques are required.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

No reviews yet.

Is it possible to get my hand on 100 sets of these?

This is awesome. Only difference I see from the springs of youth is that those were tapered, so they could "screw" into the cardboard panel that held everything in place.

Are both ends flattened? I'm considering using these to make a bendy connection between two PCBs.

Edit: I have some now. Only one end is flattened, but both ends can be soldered onto a PCB without much trouble.

I was wondering, what dimensions 0.25x0.35" mean? 0.25" is diameter and 0.35" is height? What SMD land pattern would you recommend? Thanks

re. dimensions: yes

re. SMD pad: see the note in the description; download the eagle library, you'll find it as device M01 in SparkFun-Connectors.lbr, variant SPRING-CONN (SPRING-CONNECTOR package).

Thank you but I have Eagle version 5.11.0, so new libraries are no go. There is no SPRING-CONN in libraries for older Eagle versions. Could someone please add it to older GIT repository?

Ah - I definitely recommend upgrading! I should have an old 5.11.0 install around if push comes to shove, but maybe this screenshot will suffice - the pad is just an 0.28" diameter round pad. http://i.imgur.com/urRBuGp.png

It will definitely suffice! Thank you again, kind stranger :)

You can also upgrade to the new version of Eagle with the freeware download here.

is the price for each spring or for each pack of 10?

It's for a pack of 10

I got some of these and they are a lot sturdier than I expected. I soldered the component on a piece of perfboard like in the video (this was very easy) and fought with it with a pair of pliers -- it took quite a bit of force before I was able to stretch the spring out permanently. Also, the spring could firmly hold on to 4 wires easily. And they're cheap!

Oh wow, right down nostalgia alley...

Wow. suddenly i have flashbacks from when i was 10 and got a simple electronics board...man it was awesome...altough i never managed to get the AM receiver project to work, later i found out that the speaker was popped... it was a cheap set but still the starting point of my interest in electronics!

As someone who grew up with 3 or 4 of those radio shack spring terminal 100 in 1 or whatever kits, I was happy to see these. The demo box you built reminded me strongly of those.

From what material are these made? They don't seem as ductile as copper and still allow the solder to stick to them.

Nice addition, but I have one nagging feeling... Due to the the various bending and torsional stresses these things are likely to encounter, shouldn't one side have a tab bent out and straightened for through-hole mounting? Even if the whole bottom diameter is well soldered, I can't image springs that rely on just a surface mount connection holding up to the use (or should I say abuse) I put my electronics learning lab through when I was a kid...;)

In the video, the showed how easy it was to solder these down to a board, or even a perfboard and it seemed fairly sturdy. Also, as a kid, these things were typically shoved into cardboard--something not exactly known for strength.

check the video coming later today, they're surprisingly sturdy. without pliers, I can't rip one off once it's soldered on.

OK, seeing the demonstration convinced me. :)