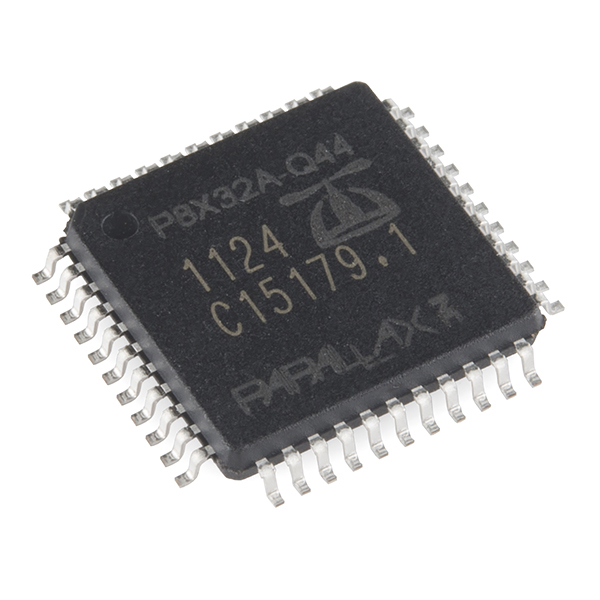

Propeller P8X32A IC

The Propeller P8X32A chip is designed to provide high-speed processing for embedded systems while maintaining low current consumption and a small physical footprint. Instead of trying to funnel all of your operations through one CPU, the Propeller runs eight separate 32-bit cores (called "cogs") so you can perform several functions in parallel! Each cog has direct access to the system clock and all GPIO pins simultaneously as well as round-robin access to 64K shared memory (32K RAM/32K ROM) Each of the Propeller's eight cogs also has two dedicated hardware counters and two special "video registers" for generating timing signals (VGA, NTSC, Servo, etc.)

Propeller P8X32A IC Product Help and Resources

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Competent - You will encounter surface mount components and basic SMD soldering techniques are required.

See all skill levels

Core Skill: Programming

If a board needs code or communicates somehow, you're going to need to know how to program or interface with it. The programming skill is all about communication and code.

Skill Level: Competent - The toolchain for programming is a bit more complex and will examples may not be explicitly provided for you. You will be required to have a fundamental knowledge of programming and be required to provide your own code. You may need to modify existing libraries or code to work with your specific hardware. Sensor and hardware interfaces will be SPI or I2C.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Competent - You will be required to reference a datasheet or schematic to know how to use a component. Your knowledge of a datasheet will only require basic features like power requirements, pinouts, or communications type. Also, you may need a power supply that?s greater than 12V or more than 1A worth of current.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

5 out of 5

Based on 1 ratings:

4 of 4 found this helpful:

A remarkable and wonderful product

The purpose of the device was to assist in the design (be a part of it) of a multi-rotational system used in the analysis of dextran (an enzyme in sugar cane - this is what destroys the sucrose in sugar can e if it is not processed within 72 hours of harvesting). Initially the system was designed with an arduino and a couple stepper motor drivers but there were hitches sometimes when the spindles rotated due to the delays on the motor (each motor had its own rpm and thus delay settable independently of the others).

This proved to be quite problematic for the arduino (it didn't like it at all).

I have since redesigned the system to use the P8X32A the concept is that each COG (only five required) is used to control an independent motor with the dedicated timer used to process delays and the dedicated COG RAM used to hold motor specific information such as timing related values.

I can then use the 6th COG to control a serial interface to the computer which can have real-time (of course a possible 14 to 16 ms delays :) worst case) response to command since the device will also be controllable from a windows application and also possibly remotely.

The 7th COG will be used to control the display and the Keypad interface.

The 8th COG will be reserved for future use.

All of this would be hell trying to do it on an arduino for timing response reasons plus alot of blocking code (Spend too much time in interrupts when large data payloads are being sent or received VIA the serial port(s), delays when updating display, monitoring the motors and ensuring the samples are rotated at the specific speed as this is important for the reaction of the enzymes with the dextran......alot of different variables and i did not want to use a 32BIT system (mbed, Rasp. PI, Beaglebone, Edison, Custom Built AT32UC3B system. Have them all but wanted a simple way of doing what i wanted without using OVERKILL, something that worked and worked well.

The Propeller P8X32A did this for me.

Thanks again, if it wasn't for sparkfun i wouldn't have known of its existence.

you guys should carry the DIP version

SparkFun's ProtoBoard works well with the Propeller chip. You'll want to use 0.1uF caps close to each of the four Vdd pins. Unfortunately SparkFun's Propeller bob doesn't have these bypass caps. The Propeller's PLL circuit is very sensitive to current running through them. The Vdd pins all need to be powered at the same voltage to prevent damage. The best way to keep all the Vdd pins at the same voltage is to provide each pin with its own bypass cap.

I'm a big fan of the Propeller myself. It makes a great controller chip for robotic projects.

the links are incorrect :(

thank you

Fixed, thank you very much!