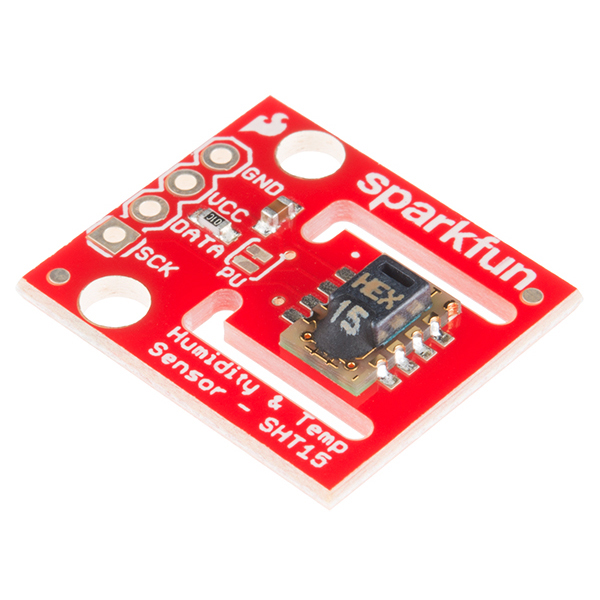

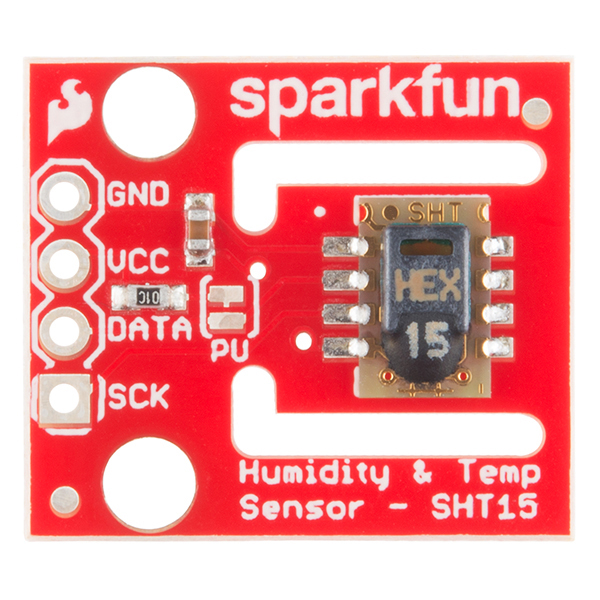

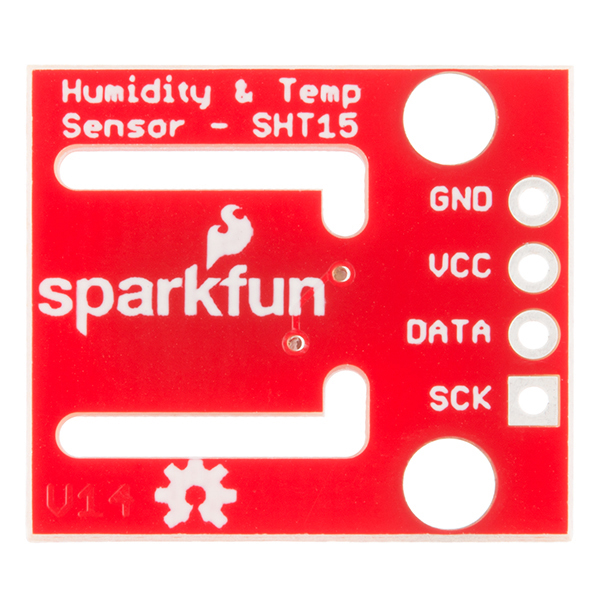

SparkFun Humidity and Temperature Sensor Breakout - SHT15

The SHT15 Breakout is an easy to use, highly accurate, digital temperature and humidity sensor. This board has been fully calibrated and offers high precision and excellent long-term stability at low cost. The digital CMOSens® technology integrates two sensors and readout circuitry on one single chip. All you need is two lines for 2-wire communication, and you’ll have relative humidity and temperature readings to help you sense the world around you!

The two sensors built into the SHT15 have been seamlessly coupled to a 14bit analog to digital converter and a serial interface circuit resulting in superior signal quality, fast response time, and a strong resistance to external disturbances. Additionally, the on board SHT15 features a 0-100% RH measurement range with a temperature accuracy of +/- 0.3°C @ 25°C. There are only four pins that need to be hooked up in order to start using this sensor in a project. One for VCC, one for GND, and the two data lines SDA and SCL.

- Operating Voltages: 2.4V min - 5.5V max

- 2 factory calibrated sensors for relative humidity & temperature

- Digital 2-wire interface (Not I2C, but similar)

- Measurement range: 0-100% RH

- Absolute RH accuracy: +/- 2% RH (10…90% RH)

- Repeatability RH: +/- 0.1% RH

- Temp. accuracy: +/- 0.3°C @ 25°C

- Precise dewpoint calculation possible

- Fast response time

- Low power consumption (typ. 30 µW)

- Schematic

- Eagle Files

- Hookup Guide

- Datasheet (SHT1x)

- GitHub

SparkFun Humidity and Temperature Sensor Breakout - SHT15 Product Help and Resources

Core Skill: Soldering

This skill defines how difficult the soldering is on a particular product. It might be a couple simple solder joints, or require special reflow tools.

Skill Level: Noob - Some basic soldering is required, but it is limited to a just a few pins, basic through-hole soldering, and couple (if any) polarized components. A basic soldering iron is all you should need.

See all skill levels

Core Skill: Programming

If a board needs code or communicates somehow, you're going to need to know how to program or interface with it. The programming skill is all about communication and code.

Skill Level: Rookie - You will need a better fundamental understand of what code is, and how it works. You will be using beginner-level software and development tools like Arduino. You will be dealing directly with code, but numerous examples and libraries are available. Sensors or shields will communicate with serial or TTL.

See all skill levels

Core Skill: Electrical Prototyping

If it requires power, you need to know how much, what all the pins do, and how to hook it up. You may need to reference datasheets, schematics, and know the ins and outs of electronics.

Skill Level: Rookie - You may be required to know a bit more about the component, such as orientation, or how to hook it up, in addition to power requirements. You will need to understand polarized components.

See all skill levels

Comments

Looking for answers to technical questions?

We welcome your comments and suggestions below. However, if you are looking for solutions to technical questions please see our Technical Assistance page.

Customer Reviews

4 out of 5

Based on 1 ratings:

Nice device, not sure how best to mount

I'm kind of a newbie to Raspberry PI. This was easy to wire up and the code examples I found were easy to modify. But I wanted to create a permanent device. I ended up soldering my leads directly to the SHT-15 and using pin connectors to attach to the Pi. That all worked. I put the Pi in an enclosure and mounted the SHT-15 onto the outside of the enclosure with (roughly) 3/4" standoffs. Configured like this it reads 4-5" hotter than actual temperature. Not sure why. I could move the sensor farther from the Pi enclosure but I've not come up with an idea that works and wouldn't make the sensor vulnerable to being detached.

I have bought this sensor a bit more than one year ago to control a fan in my bathroom. I have put the sensor at the entrance of the air pipe. It was working great but after one year and some hundred showers, the humidity sensor stopped working. When I checked it, it was looking like it was 50 years old: full of dust and oxydation. I tried to clean it but it did not help.

I might buy a new one, but I don't want that to happen again. I am looking for suggestions on how to protect this curcuit against the strong and wet wind inside an air pipe, without preventing the humidity sensor for working.

Thanks.

Hi, For starters, using a PTFE filter to cover the sensor opening will help give it a longer lifetime. (Spoiler alert) SparkFun will be selling a new temp/humidity sensor with a PTFE filter pre-installed very soon. You can also use conformal coating to cover all the electronics and a connections to make them more weatherproof. You can find kits like this one online. We also have some suggestions in this tutorial. Hope that helps!

Thanks for your answer. That's great news for this new protected sensor, any idea when this will be released? Will it be compatible with sht15?

Just letting you know we released the Si7021, which is the sensor I was mentioning.

Can't say exactly when it will be released. Unfortunately, it will not be a drop-in replacement for the SHT15 but it will be for the HTU21D. The good news is, it will be significantly cheaper than the SHT15.

The "L" shaped channels reduce heat transfer according to the datasheet. Not sure where the heat is coming from on the breakout boards, though. I believe that it lowers the thermal inertia for the sensor which may make it a little more responsive to temperature changes.

Is the purpose of the two 'L' shaped channels so the board can be cut to reduce size? Or am I about to destroy my breakout?

lol, I suppose you could make it smaller if you wanted. The purpose of the milled-out L shapes is to help with parasitic heat from a system. If you had this sensor soldered to a board that ran warmer than the environment you're trying to measure, it will give you inaccurate data. Not having a copper pour and reducing the surface area of the PCB helps to keep the readings from the sensor closer to accurate.

Looks awesome and I'm sure it runs great. However my dyslexic mind keeps seeing the model number as a word that is synonymous with the stuff a dog would leave on your lawn. Consider putting a dash "-" between the letters and numbers of the model number.

;) SHT15 is the part number for the chip - SparkFun didn't pick it. (Well, they picked the part for this BOB, but they didn't pick the name/number for the part).

This appears to have a response time of 8 seconds, but a read delay of 320ms at full resolution, so I am guessing response time is the lag between actual temperature change and measured temperature change, but update polling can be about 3 times a second.

I agree with your concussion that the 8 Second Response Time is the time the sensors take to respond to an increase or decrease in the temperature or humidity.

Per the docs, "... SHT1x should not be active for more than 10% of the time – e.g. maximum one measurement per second at 12 Bit accuracy shall be made ..."

So if the SHT15 takes 320 milliseconds to process a 14 bit measurement then you "should not" poll more than ONCE every 3 seconds to maintain 10% On-Time and 90% Off-Time requirement. Do not POLL 3 times per second.