SMD How To - 3

Rework with just an iron = Bad

So you've neglected to correctly identify pin 1 of your IC and you've soldered the thing on completely backwards. If you're lucky, you've noticed this before powering the board and vaporizing traces. How do you get an SMD IC off a PCB?

There are a few ways to remove an SMD component with just an iron. Pretty much all will destroy the component and potentially the PCB so these are just for informational purposes only:

1) Wick and flex. If you're trying to remove a resistor or cap with only two pins, wick away most of the solder on the pins. With hemostats, grip the piece, heat one pad and flex the component away from the molten pad. Now remove the iron - the pad will cool and the component should only be held on by one pin. Heat that pin and remove the component. This stresses the hell out of the last pad but it works.

2) Blob and swipe. If the 2-pin component is small enough (0603s especially), you can get a good blob of solder on the tip of your iron and heat both pads of the resistor or cap simultaneously.

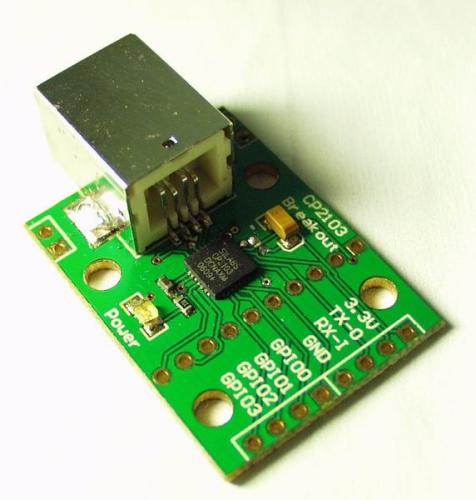

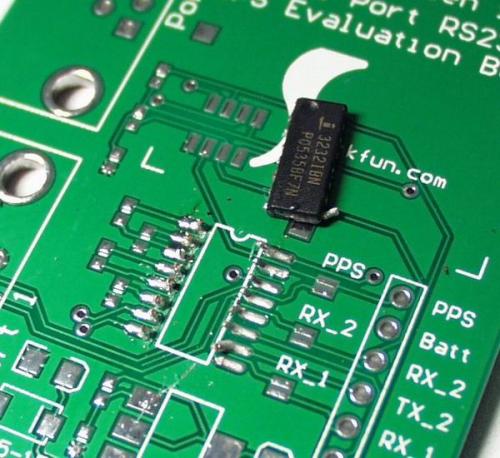

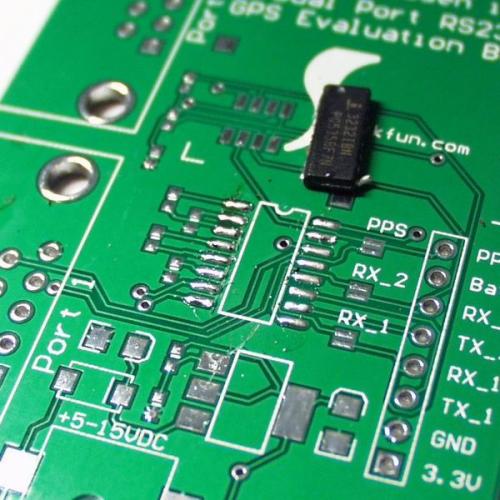

Here's a breakout board. Let's remove the 0603 resistor near the Power LED

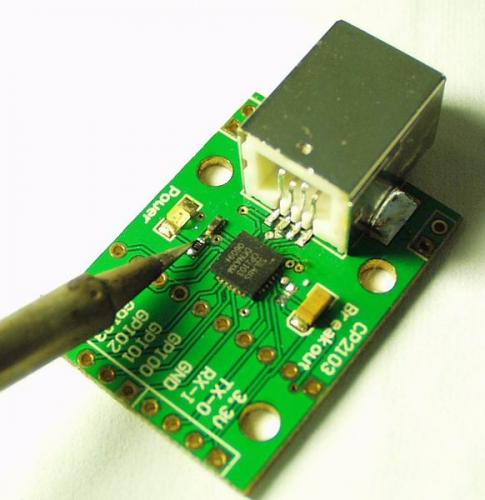

Add solder to both ends of the resistor

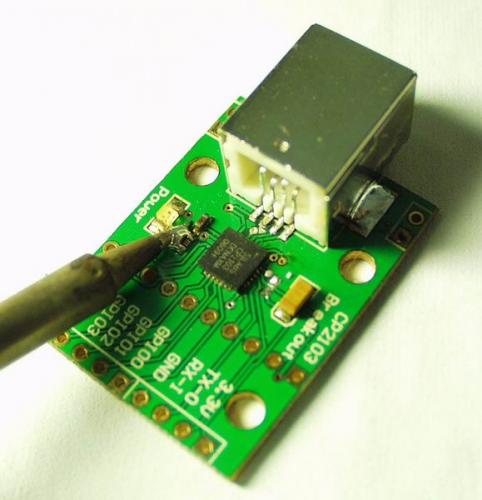

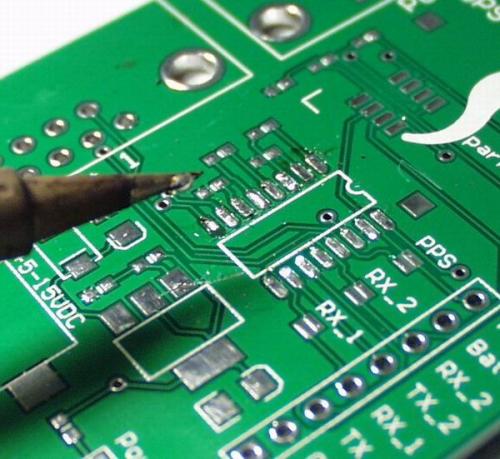

Push lightly side ways and the component should slide away after a split second.

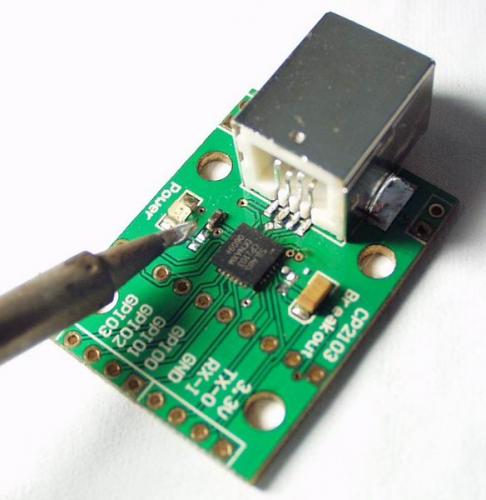

You'll end up with the component on the tip of your iron.

3) Score and flex. If you're trying to remove a multi-pin device with leads, you can use an exacto knife to score the pins near the component housing.

Be careful not to push down too hard or the knife will go through the pin legs and scratch or cut traces on the PCB below.

Once you've got one side scored or cut, score the opposite side and flex the component upwards. Flex until the pins break.

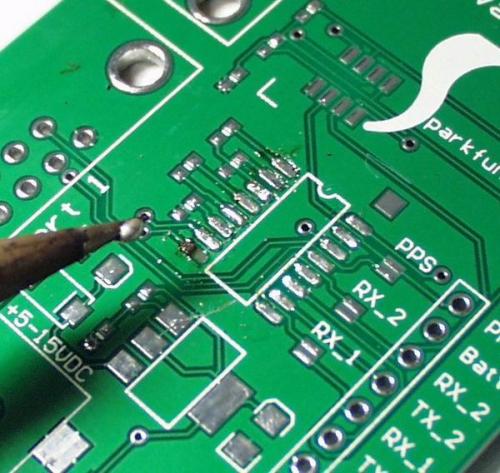

Once the main component is gone, run the iron around the pads with a bit of solder on the tip releasing all the cut and broken pins from the pads and onto the tip of the iron.

You may need to clear jumpers between pads with wick before attempting to remount the IC.

This process is tricky and can only be done once (maybe twice) before the heat/re-heat causes the pads to lift from the PCB.

Here's what happens! With the best intentions, I still managed to completely kill the pad. It is no more. But! We can fix this. More on 'green' wiring later.

4) There are commercial products and/or tricks out there that I have not used and do not endorse but aid in the removal of a soldered IC. These products are composed primarily of an alloy that is added to the soldered leads of an IC. This alloy has a lower melting point than standard solder so as you heat this alloy with a standard iron, it stays molten for much longer. This allows you to move the iron around while the alloy stays molten, and once you have all the leads molten, you then pull out the IC. I'm not sure what the cost is, but this may be a cheaper method, initially, than a hot-air rework station.

5) Removing or adjusting leadless IC like a QFN is impossible with an iron. The PCB would be destroyed and the IC along with it. You need hot air!

Page 4 - Wonderful hot-air rework

Okay, I know these guides are for people who probably haven't got a certificate in soldering, or the tools to "do the right thing". But the knife on the board, that's up to no good.

Instead, I would use diagonal cutter, to cut every leg on the small IC. Then use the soldering iron to remove with the tiny leftovers, by means of capillarity.

This makes sure that you don't damage your boards.

Then you could use solder wick to remove leftover solder, or use a vacuum soldering iron as John Price says.

Sorry if I upset anyone.

Regards,

Lerche

I agree, use some small precision side cutters to cut each IC lead individually. Hint to Sparkfun, get in some small precision side cutters, to sell to your customers, for this task. I have a pair of Swiss made side cutters and they work like a charm. @Lerche, you should not think that you are upsetting anyone, when you are in fact trying to save someone one big headache, if they cut through one or more PCB traces and damage a potentially very expensive PCB. They should, in fact, re-write this article showing our suggested method, as the method in this article is flawed and not recommended by trained people!! Look at an IPC spec if you do not agree!1 http://www.lindstromtools.us

Rick

It is a good idea to use one of those commercially available multi-pin sockets. One solders one or more of those into the pcb instead of the ic/ics. Then one places the ic/ics into the socket. If one has made an error, then one runs the risk of sacrificing an ic socket which generally has little monetary or functional value and saves the much more valuable ic/ics.

I have a vacuum soldering iron that does a decent job at removing more solder than wick, freeing the lead. With it you can (eventually) remove anything with through the board leads one lead at a time and cheaper than a hot air machine.